Vacuum pressure impregnation insulation process for stator strip coils of large high-voltage shielded motors

A shielded motor, high-voltage technology, applied in the field of vacuum pressure impregnation insulation technology of large-scale high-voltage shielded motor stator strip coil, which can solve the problems of large deformation and increased core diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

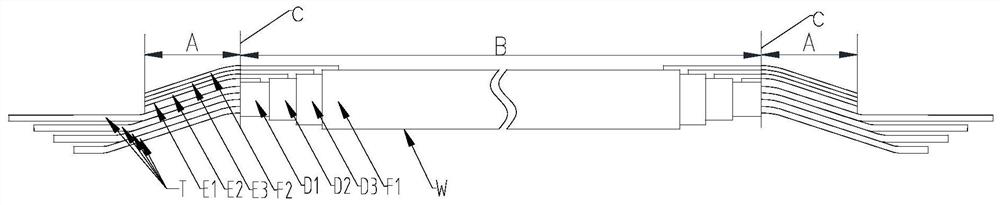

[0022] Such as figure 1 A large-scale high-voltage shielded motor stator strip coil VPI insulation process for the coil shown, the implementation steps are as follows:

[0023] 1) Draw line C1 and line C2 respectively at the tangent point between the straight line part B of the strip-formed coil conductor T and the inner corner A of the ends A of the coil conductor;

[0024] 2) Start from line C1 and wrap the first layer of insulating tape D1 half-fold along the straight line part B of the coil to line C2 at the other end of the straight line B of the coil. The start and end positions are set on the narrow side W of the coil, and Adhesive tape head;

[0025] 3) Start the second layer of D2 insulation tape wrapping with half the insulation bandwidth back from the first layer of insulation D1 wrapping, and end the wrapping at half a bandwidth away from the end of the first layer of insulation tape D1, and use adhesive tape at the end head;

[0026] 4) According to step 3), co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com