A kind of polymer resin and its application in high frequency circuit board

A polymer, polyphenylene ether resin technology, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of low glass transition temperature, high brittleness, high thermal expansion coefficient, and achieve vitrification. The effect of high transition temperature, meeting the requirements of toughness and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

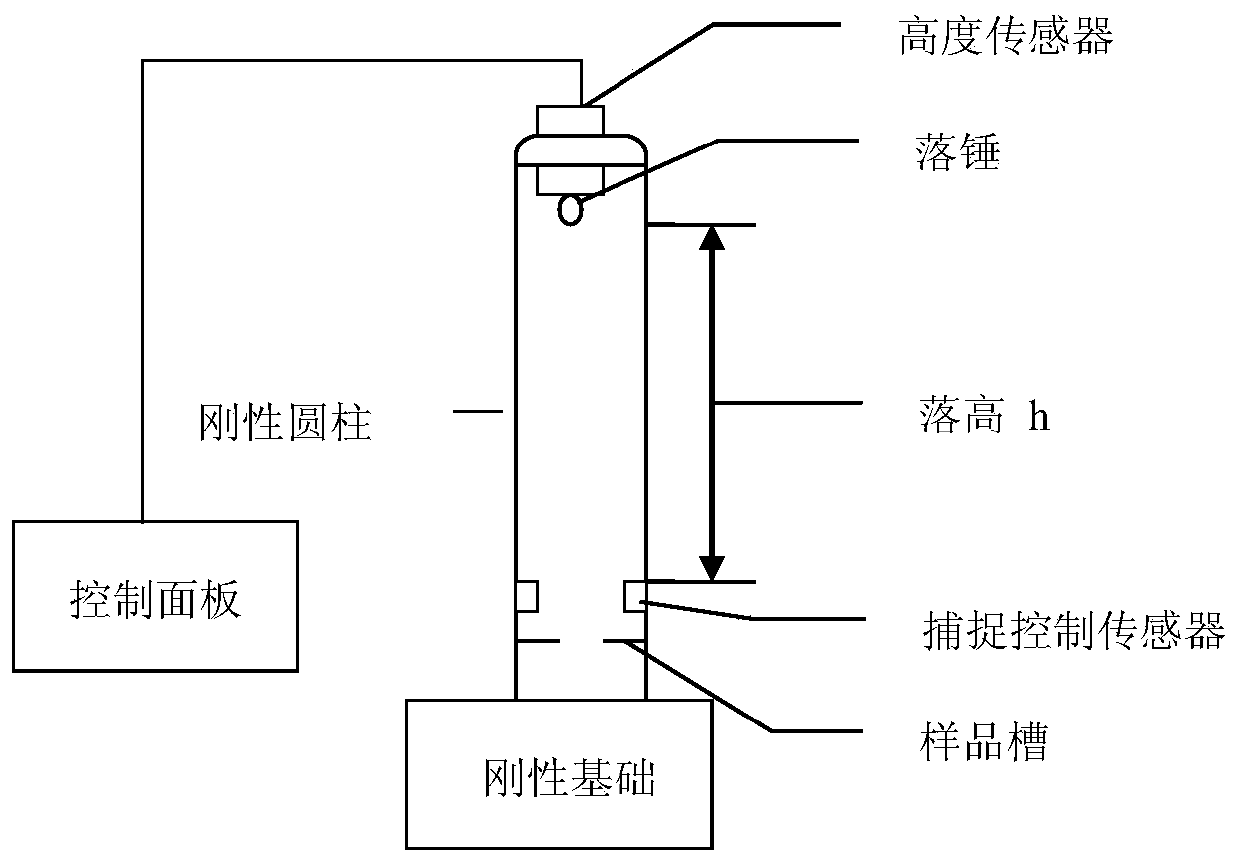

Image

Examples

preparation example 1

[0092] Synthesis of Vinylbenzyl Ether Modified Poly(p-Hydroxystyryl-styrene) Polymer SY-1:

[0093] Dissolve S-1 containing 1 mol of phenolic hydroxyl group in ethanol solvent, stir until it is completely dissolved, heat up to 50°C, and blow nitrogen gas for 30 minutes; add 1.2 mol of sodium methoxide and react for 1 hour; add 1.2 mol of vinylbenzyl chloride , reacted for 8 hours; after the reaction, the product was precipitated from ethanol, added toluene for dissolution, and washed 1 or 2 times; then dropped into ethanol to precipitate, and the precipitated product was dissolved in toluene to obtain vinyl benzyl ether modified poly(p- Hydroxystyryl-styrene) polymer SY-1, ready for use.

preparation example 2

[0095] Synthesis of vinylbenzyl ether modified poly(p-hydroxystyrene-styrene) polymer SY-2:

[0096] Dissolve CST15 containing 1 mol of phenolic hydroxyl group in ethanol solvent, stir until it is completely dissolved, heat up to 50°C, and blow nitrogen gas for 30 minutes; add 1.2 mol of sodium methoxide, and react for 1 hour; add 1.2 mol of vinylbenzyl chloride, and react 8 hours; after the reaction, the product was precipitated from ethanol, dissolved in toluene, washed once or twice with water; then dropped into ethanol to precipitate, and the precipitated product was dissolved in toluene to obtain vinyl benzyl ether modified poly(p-hydroxyphenyl Vinyl-styrene) polymer SY-2, ready for use.

preparation example 3

[0098] Synthesis of Vinylbenzyl Ether Modified Poly(p-Hydroxystyryl-styrene) Polymer SY-3:

[0099] Dissolve CST50 containing 1 mol of phenolic hydroxyl group in ethanol solvent, mechanically stir until it is completely dissolved, heat up to 50°C, and pass nitrogen gas for 30 minutes; add 1.2 mol of sodium methoxide, and react for 1 hour; add 1.2 mol of vinylbenzyl chloride, and react 8 hours; after the reaction, the product was precipitated from ethanol, dissolved in toluene, washed once or twice with water; then dropped into ethanol to precipitate, and the precipitated product was dissolved in toluene to obtain vinyl benzyl ether modified poly(p-hydroxyphenyl Vinyl-styrene) polymer SY-3, ready for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com