A kind of anti-tiger skin texture polypropylene resin composition and preparation method thereof

A polypropylene resin, anti-tiger grain technology, applied in the field of polymer material modification, can solve the problems of tiger skin grain, flow marks, etc., to improve the crystallization temperature, avoid flow imbalance, and excellent toughening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

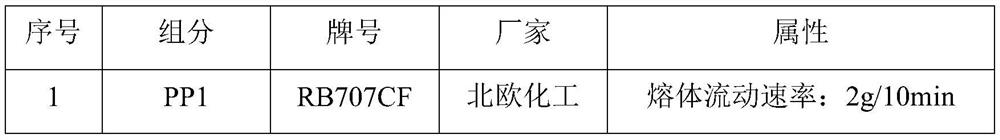

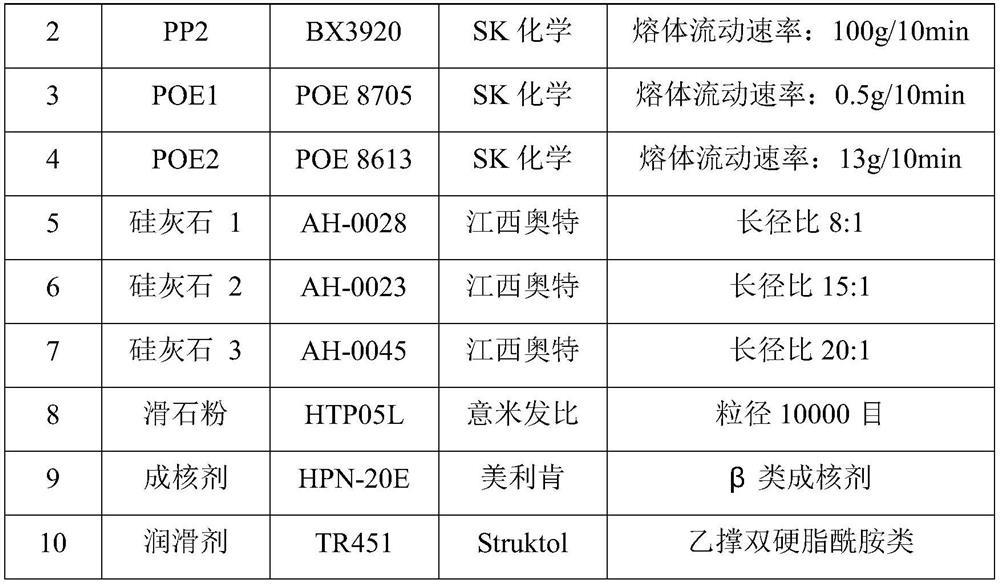

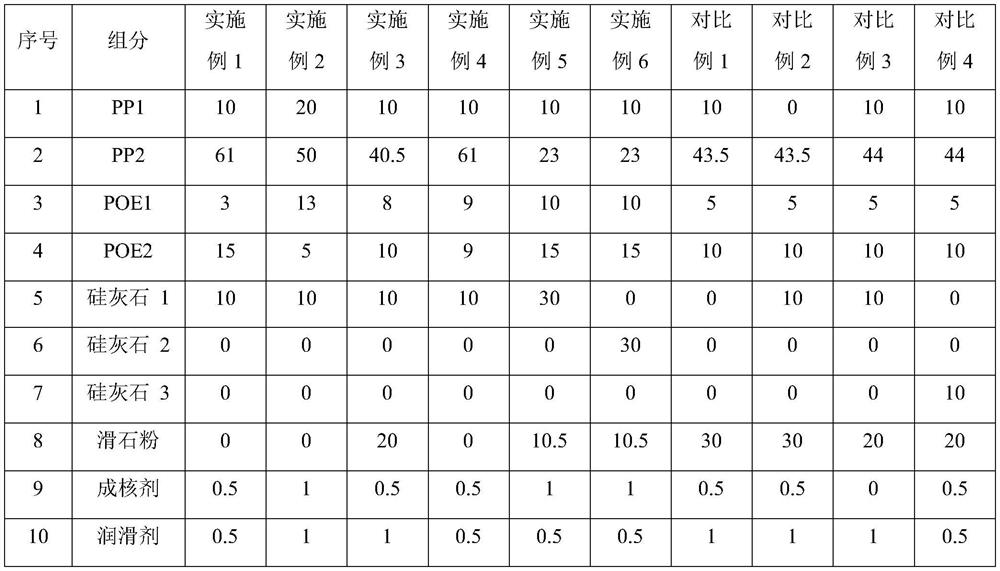

Method used

Image

Examples

Embodiment 7

[0039] The first copolymerized polypropylene (230°C, 2.16kg melt flow rate: 0.5g / 10min), the second copolymerized polypropylene (230°C, 2.16kg melt flow rate: 30g / 10min), ethylene-propylene copolymer ( 190°C, 2.16kg melt flow rate: 0.5g / 10min), ethylene-butene copolymer (190°C, 2.16kg melt flow rate: 10g / 10min), talc powder with a particle size of 5000 meshes, an aspect ratio of 10:1 wollastonite, β-type nucleating agent and ethylene bis-stearamide were placed in a high-speed mixing pot and mixed for 5 minutes according to the ratio in Example 1. The remaining preparation steps were the same as those in Example 1. The finished product of the anti-tiger skin texture polypropylene resin composition.

Embodiment 8

[0041] 10% of the first copolymerized polypropylene (230°C, 2.16kg melt flow rate: 3g / 10min), 64% of the second copolymerized polypropylene (230°C, 2.16kg melt flow rate: 60g / 10min), 5% ethylene-propylene copolymer (190°C, 2.16kg melt flow rate: 1 g / 10min), 5% ethylene-butene copolymer (190°C, 2.16kg melt flow rate: 30g / 10min), 5% pellets The talc powder with a diameter of 7000 meshes, 10% wollastonite with an aspect ratio of 10:1, 0.5% β-type nucleating agent, and 0.5% ethylene bis-stearamide were prepared according to the same preparation method as in Example 1. The finished product of the tiger skin pattern polypropylene resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com