Polymer resin composition and application thereof to high-frequency circuit boards

A polymer and composition technology, applied in the direction of circuit substrate materials, applications, printed circuits, etc., can solve the problems of high cross-linking density, high brittleness, large dielectric constant and dielectric loss of the substrate, etc., and achieve thermal expansion coefficient The effect of low, low dielectric loss and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

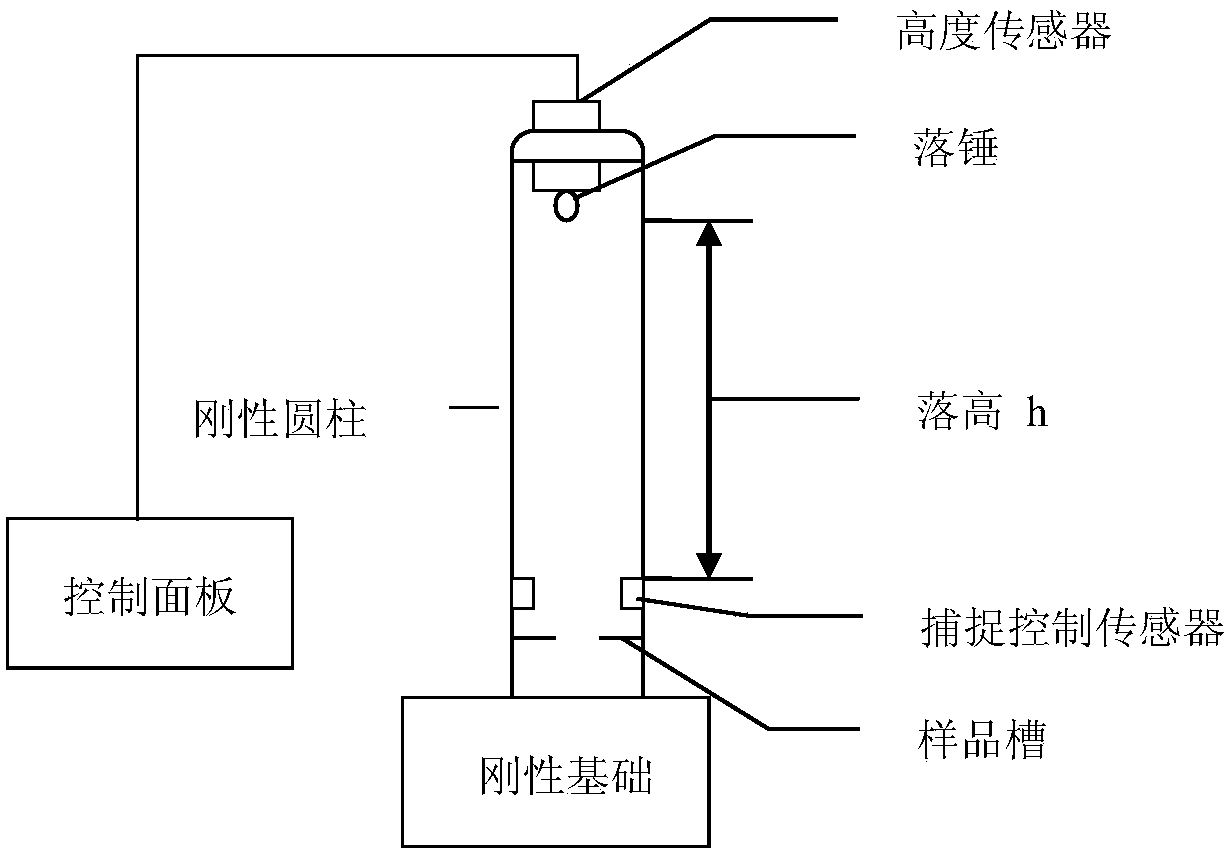

Image

Examples

preparation example 1

[0087] Synthesis of Vinylbenzyl Ether Modified Poly(p-Hydroxystyryl-styrene) Polymer SY-1:

[0088] Dissolve S-1 containing 1 mol of phenolic hydroxyl group in ethanol solvent, stir until it is completely dissolved, heat up to 50°C, and blow nitrogen gas for 30 minutes; add 1.2 mol of sodium methoxide and react for 1 hour; add 1.2 mol of vinylbenzyl chloride , reacted for 8 hours; after the reaction, the product was precipitated from ethanol, added toluene for dissolution, and washed 1 or 2 times; then dropped into ethanol to precipitate, and the precipitated product was dissolved in toluene to obtain vinyl benzyl ether modified poly(p- Hydroxystyryl-styrene) polymer SY-1, ready for use.

preparation example 2

[0090] Synthesis of vinylbenzyl ether modified poly(p-hydroxystyrene-styrene) polymer SY-2:

[0091] Dissolve CST15 containing 1 mol of phenolic hydroxyl group in ethanol solvent, stir until it is completely dissolved, heat up to 50°C, and blow nitrogen gas for 30 minutes; add 1.2 mol of sodium methoxide, and react for 1 hour; add 1.2 mol of vinylbenzyl chloride, and react 8 hours; after the reaction, the product was precipitated from ethanol, dissolved in toluene, washed once or twice with water; then dropped into ethanol to precipitate, and the precipitated product was dissolved in toluene to obtain vinyl benzyl ether modified poly(p-hydroxyphenyl Vinyl-styrene) polymer SY-2, ready for use.

preparation example 3

[0093] Synthesis of Vinylbenzyl Ether Modified Poly(p-Hydroxystyryl-styrene) Polymer SY-3:

[0094] Dissolve CST50 containing 1 mol of phenolic hydroxyl group in ethanol solvent, mechanically stir until it is completely dissolved, heat up to 50°C, and pass nitrogen gas for 30 minutes; add 1.2 mol of sodium methoxide, and react for 1 hour; add 1.2 mol of vinylbenzyl chloride, and react 8 hours; after the reaction, the product was precipitated from ethanol, dissolved in toluene, washed once or twice with water; then dropped into ethanol to precipitate, and the precipitated product was dissolved in toluene to obtain vinyl benzyl ether modified poly(p-hydroxyphenyl Vinyl-styrene) polymer SY-3, ready for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com