The manufacturing method of high-strength plate q960 produced by the steel coil rolling mill

The technology of a furnace coil rolling mill and a manufacturing method is applied in the field of metal materials to achieve the effects of low carbon equivalent, stable comprehensive performance and flat shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A method for producing high-strength plate Q960 by a steckel mill, the method comprising the following steps:

[0017] 1) In terms of smelting process, converter steelmaking is adopted, top-lower compound blowing is used for deep decarburization; RH vacuum treatment is used for further decarburization, and microalloying is carried out to obtain a billet that meets the requirements; the weight percentage of the chemical composition of the billet is: C 0.12~0.20%, Mn 0.80~1.60%, Si0.02~0.40, P≤0.015, S≤0.005, B 0.001~0.003, and add appropriate amount of Cr, Mo, V, Ni alloy elements, and satisfy the carbon equivalent Ceq= +Mn / 6+Cr / 5+Mo / 4+V / 14+Ni / 40+Si / 24≤0.60;

[0018] 2) In terms of rolling process, the steel billet is used for controlled rolling. The heating temperature of the billet before rolling is 1150-1250°C, the reduction of each pass is 10-25%, and the reduction temperature is 900-1200°C. The furnace temperature was <1000°C.

[0019] According to the present inv...

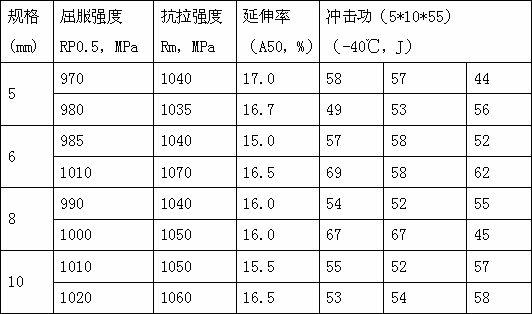

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com