A kind of x80 large-diameter thick-walled straight seam submerged arc welded pipe suitable for low temperature and its manufacturing method

A technology of straight seam submerged arc welding and manufacturing method, which is applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., to achieve good low temperature toughness, excellent low temperature toughness, and the effect of eliminating undercuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

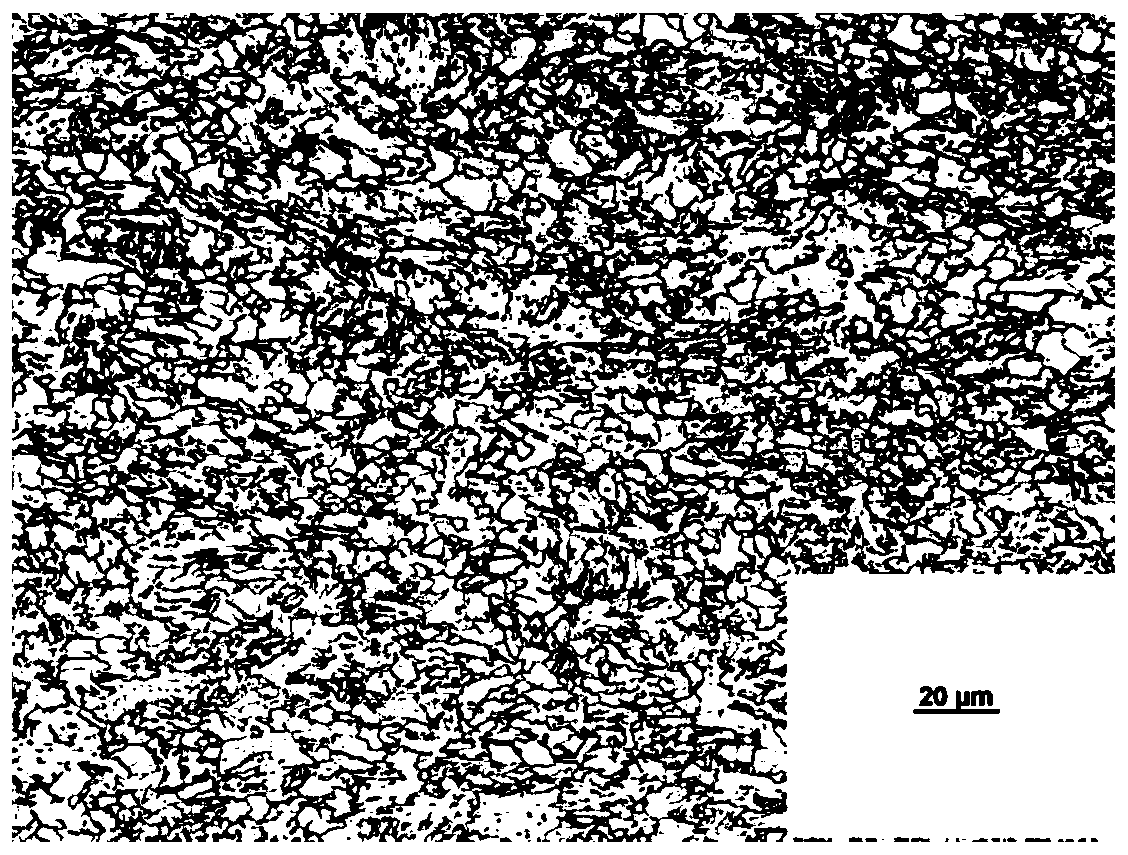

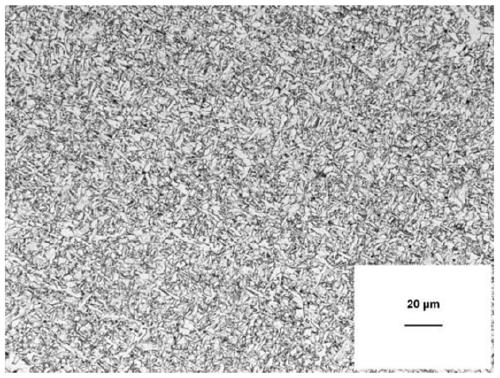

[0034] Example 1: Manufacture of X80 steel grade Φ1422×30.8mm low-temperature LSAW pipe.

[0035] (1) Raw material, X80 steel grade hot-rolled steel sheet with a wall thickness of 30.8mm is used, and its main alloying element content: C0.05%, Si 0.21%, Mn 1.67%, S 0.001%, P 0.010%, Ni 0.18%, Cr 0.16%, Cu 0.21%, Nb 0.07%, V 0.005%, Ti 0.016%, Mo 0.12%, Al 0.03%, N 0.006%, B 0.0003%, and the balance is Fe.

[0036] (2) Ultrasonic inspection of steel plate, 100% ultrasonic inspection of steel plate.

[0037] (3) For milling, the bevel size is 70° for the upper bevel, 70° for the lower bevel, 11.5mm in the depth of the lower bevel, and 10.0mm in the blunt edge.

[0038] (4) Pre-bending the edge, using a pre-bending machine to pre-bend the edge of the board to make the edge curvature meet the requirements.

[0039] (5) JCO forming, in the forming machine, first press one side of the pre-bent steel plate into a "J" shape, and then press the other half of the steel plate in the same way and p...

Embodiment 2

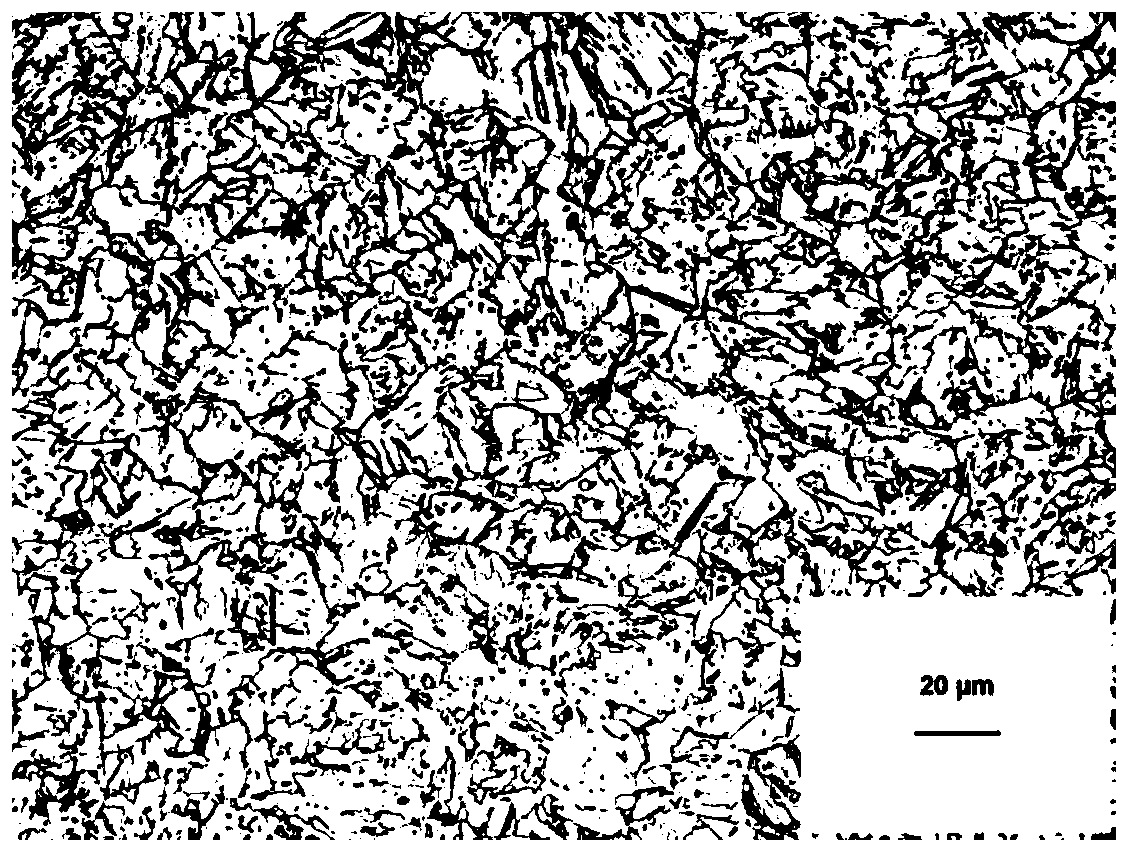

[0057] Example 2: Manufacture of X80 steel grade Φ1422×33.8mm low temperature longitudinal submerged arc welded pipe.

[0058] (1) Raw material: X80 steel grade hot-rolled steel sheet with a wall thickness of 33.8mm is used. The main alloying element content: C0.07%, Si 0.25%, Mn 1.65%, S 0.002%, P 0.010%, Ni 0.19%, Cr 0.24%, Cu 0.12%, Nb 0.05%, V 0.04%, Ti 0.016%, Mo 0.20%, Al 0.03%, N 0.005%, B 0.0003%, and the balance is Fe.

[0059] (2) Ultrasonic inspection of steel plate, 100% ultrasonic inspection of steel plate.

[0060] (3) For milling, the bevel size is 70° for the upper bevel, 70° for the lower bevel, 12.5mm in the depth of the lower bevel, and 10.0mm in the blunt edge.

[0061] (4) Pre-bending the edge, using a pre-bending machine to pre-bend the edge of the board to make the edge curvature meet the requirements.

[0062] (5) JCO forming, in the forming machine, first press one side of the pre-bent steel plate into a "J" shape, and then press the other half of the steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com