A kind of high corrosion resistance high aluminum content low density steel and its preparation method

A low-density steel and high corrosion-resistant technology, applied in the field of metal materials, can solve the problems of impact toughness and corrosion resistance, low corrosion performance, low density and high strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

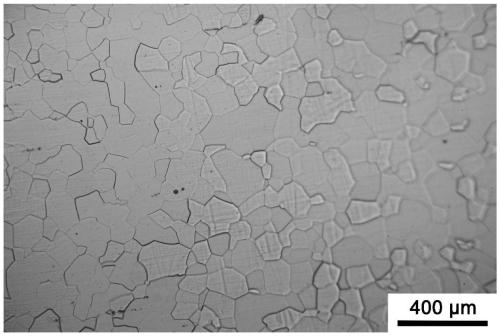

Image

Examples

Embodiment 1

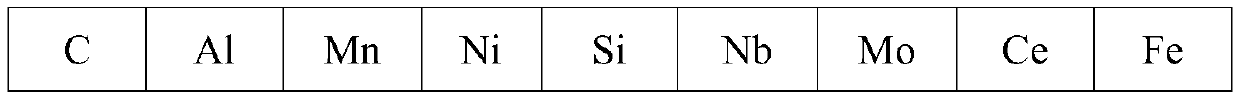

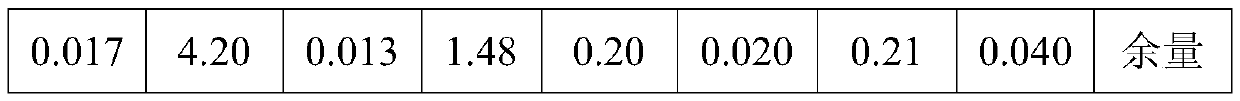

[0030] The steel grade composition (mass percentage) of embodiment 1 of the present invention is as shown in table 1

[0031] Table 1: Alloy composition (wt%)

[0032]

[0033]

[0034] After forging, the steel billet with a thickness of 170mm is held at a homogenization temperature of 1100°C for 100 minutes for homogenization treatment, and then rolled at 1000°C. The rolling is divided into 3 stages, the first stage is rolling in the recrystallization zone, 3 passes , the pass reduction rates were 15.8%, 16.6%, 17.3%, the pass intervals were 6s, 8s, 10s, and the final rolling temperature was 960°C; In the first stage, the rolling direction is rolled at 60°, 3 passes, the pass reduction rates are 22.0%, 23.1%, 23.3%, and the pass intervals are 10s, 12s, 15s; the third stage is non-recrystallization Longitudinal rolling in the zone, the same as the rolling direction of the first stage, 3 passes, the pass reduction rates are 26.1%, 26.5%, 28%, the pass intervals are 15s, ...

Embodiment 2

[0037] The steel grade composition (mass percentage) of embodiment 2 of the present invention is as shown in table 2

[0038] Table 2: Alloy composition (wt%)

[0039] C Al mn Ni Si Nb Mo Ce Fe 0.02 4.26 0.051 1.08 0.19 0.018 0.41 0.030 margin

[0040] After forging, the steel billet with a thickness of 170mm is held at a homogenization temperature of 1150°C for 80 to 120 minutes for homogenization treatment, and then rolled at 1000°C. The rolling is divided into 3 stages, the first stage is rolling in the recrystallization zone, and 3 Passes, pass reduction rates were 15.3%, 15.9%, 17.2%, pass intervals were 5s, 8s, 9s, finish rolling temperature was 955°C; Rolling at an angle of 60° to the rolling direction of the first stage, 3 passes, the pass reduction rates are 20.8%, 21.0%, 21.8%, and the pass intervals are 11s, 13s, 15s; the third stage is not Longitudinal rolling in the recrystallization zone, the same rolling direction as th...

Embodiment 3

[0043] The steel grade composition (mass percentage) of embodiment 3 of the present invention is as shown in table 3

[0044] Table 3: Alloy composition (wt%)

[0045] C Al mn Ni Si Nb Mo Ce Fe 0.018 4.26 0.042 1.06 0.19 0.020 0.29 0.032 margin

[0046] After forging, the steel billet with a thickness of 150mm is held at a homogenization temperature of 1150°C for 80 to 120 minutes for homogenization treatment, and then rolled at 1000°C. The rolling is divided into 3 stages, the first stage is rolling in the recrystallization zone, and 3 stages Passes, pass reduction rates were 16.0%, 17.5%, 19.2%, pass intervals were 6s, 9s, 10s, finish rolling temperature was 965°C; Rolling at an angle of 75° to the rolling direction of the first stage, 3 passes, the pass reduction rates are 21.4%, 25.7%, 26.5%, and the pass intervals are 11s, 14s, 14s; the third stage is not Longitudinal rolling in the recrystallization zone, the same rolling direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com