Method for improving impact performance of MCA flame-retardant PA66

A technology of impact performance and three-thread thread, which is applied in the field of improving the impact performance of MCA flame-retardant PA66, can solve the problems of high MCA addition, affecting material toughness, and insufficient dispersion of flame retardants, so as to achieve toughness improvement, sufficient dispersion, and reduction Effect of Manufacturing Cost and Formulation Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

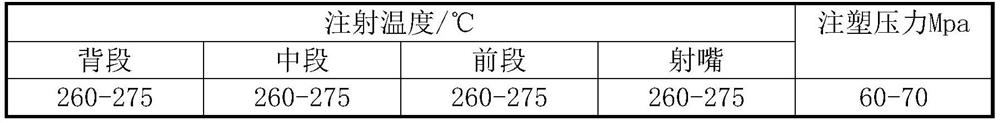

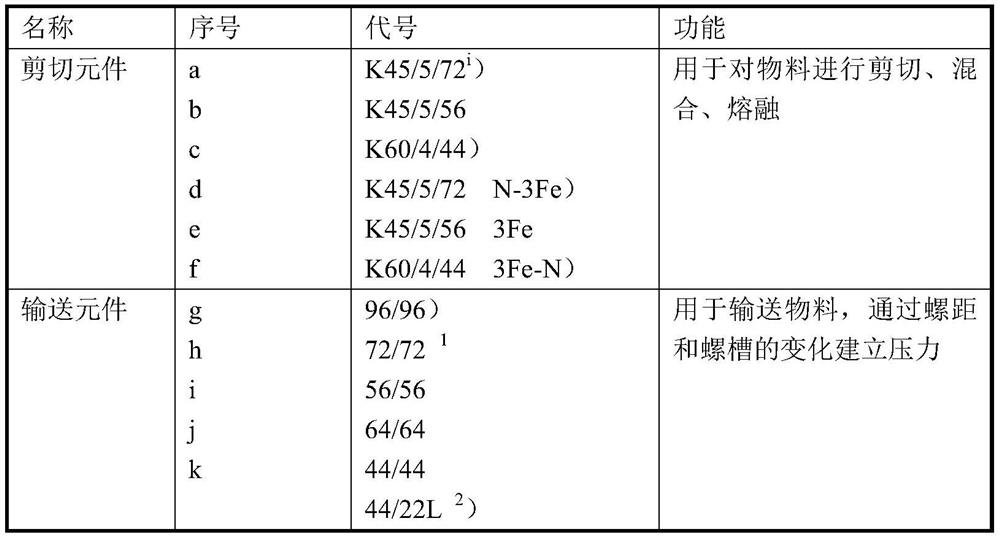

[0036] The screw of a twin-screw extruder consists of threaded elements. The used screw elements and their specifications are shown in Table 2

[0037] Table 2. Specifications of threaded components

[0038]

[0039] 1) In "K45 / 5 / 72", 45 refers to the kneading disc corner, 5 refers to 5 kneading discs, 72 refers to the total length of the element is 72mm, and others are similar;

[0040] 2) In "72 / 72", the pitch of the first 72 fingers is 72mm, the length of the last 72 fingers is 72mm, and the others are similar;

[0041] 3) In ""44 / 22L", L" refers to left-handed threaded components, and others are similar;

[0042] 4) In "K45 / 5 / 56 3Fe", 3Fe refers to three-start threaded components; "N-3Fe" and "3Fe-N" in the table refer to transitional components to double-started threaded components.

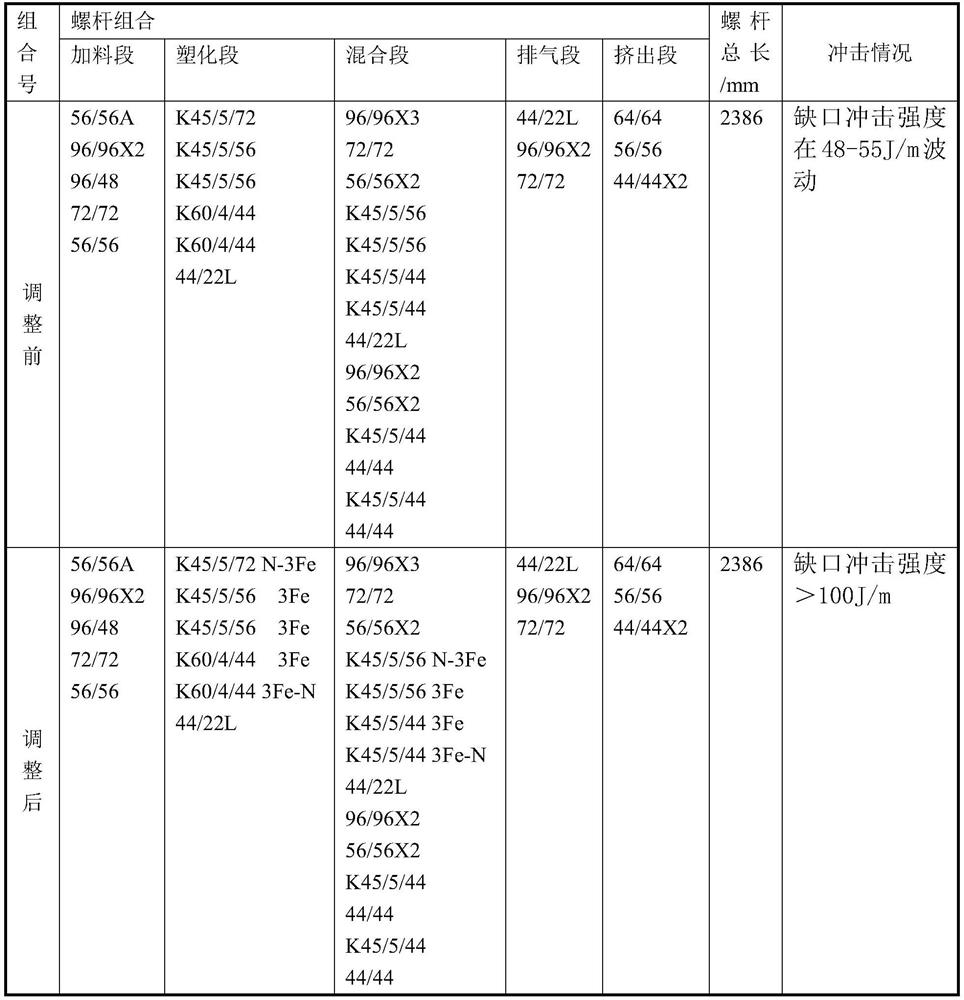

[0043] Table 3. Screw combination and extrusion process before and after adjustment

[0044]

[0045] "X2" and "X3" respectively indicate that there are two or three components.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com