Toughened modified vinyl ester resin and synthesis method thereof

A vinyl ester resin, toughening modification technology, applied in the field of toughening modified vinyl ester resin and its synthesis, to achieve the effects of clear reaction end point control, high elongation at break and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides the synthetic method of described toughening modified vinyl ester resin, comprises the following steps:

[0047] (1) Add diisocyanate and flexible diol in sequence in the reaction kettle, then add catalyst A, start stirring until the isocyanate content reaches 1-9% (mass fraction) as the reaction end point, and obtain an isocyanate-terminated polyurethane prepolymer;

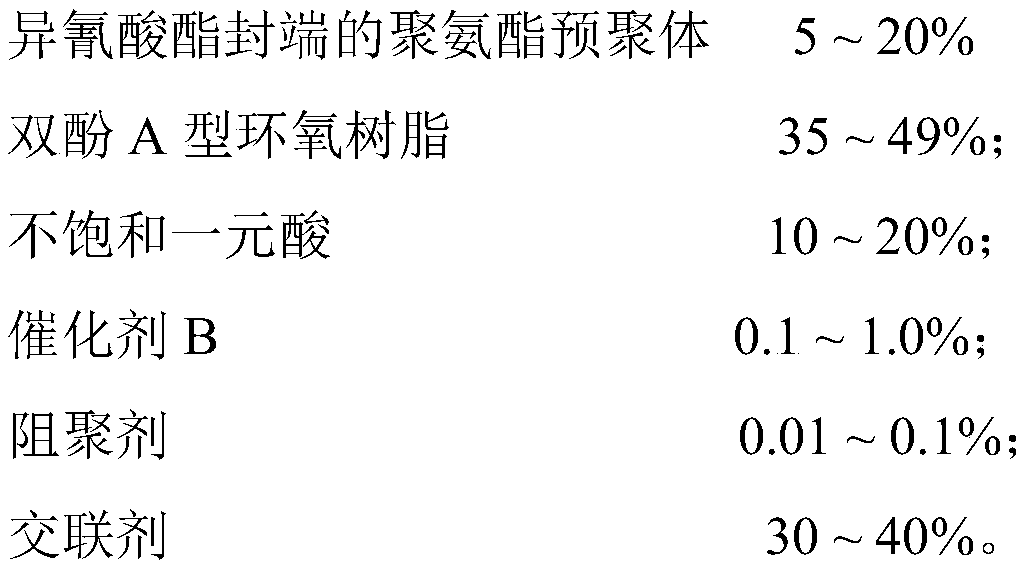

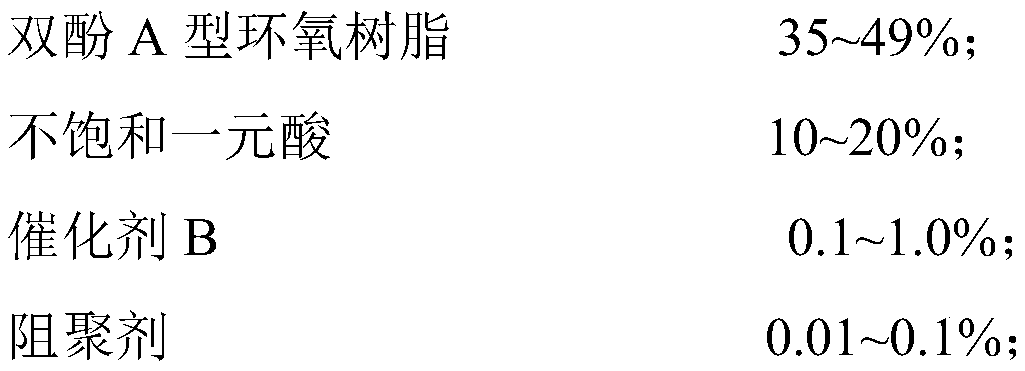

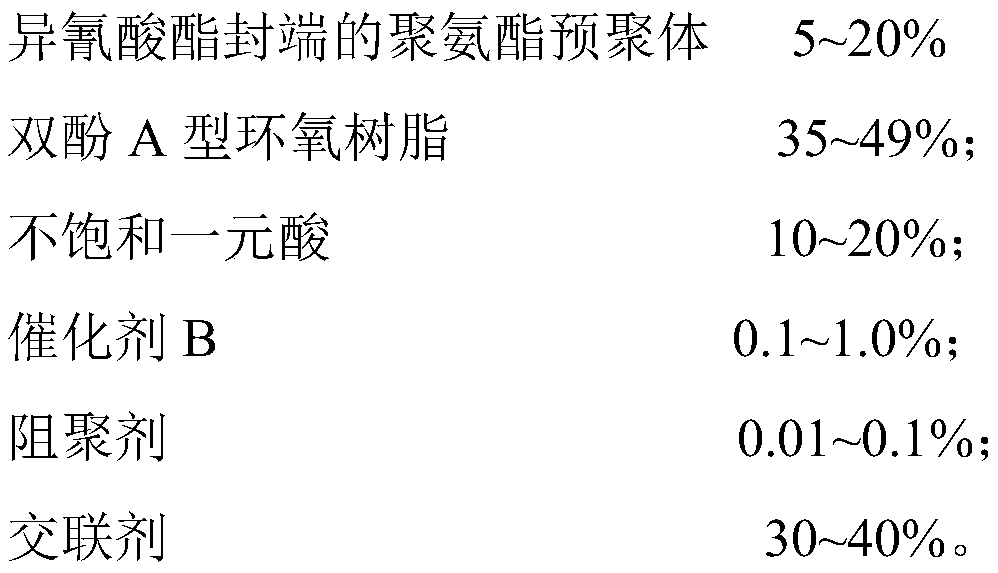

[0048] (2) In the stirred reactor, add in order by mass percentage:

[0049]

[0050] Carry out the reaction until the acid value drops below 12mgKOH / g;

[0051] (3) After cooling the reaction product obtained in step (2), add 5 to 20% of the isocyanate-terminated polyurethane prepolymer obtained in step (1) to react, and when the content of isocyanate groups is zero, the end point of the reaction is reached, and adding 30-40% cross-linking agent, stir evenly to obtain toughened modified vinyl ester resin.

[0052] In one embodiment of the present invention, in ste...

Embodiment 1

[0062] Put 3000g polyethylene glycol 600, 1890g toluene diisocyanate, 3g dibutyltin dilaurate into the reaction kettle, gradually raise the temperature to 80°C, measure the content of isocyanate group every half hour until the content of isocyanate group is 8.6%. At the end point, an isocyanate-terminated polyurethane prepolymer is obtained.

[0063] In another reaction kettle, add 1850g E-51 bisphenol A epoxy resin, 720g acrylic acid, 12.85g benzyltriethylammonium chloride, 0.1285g methyl hydrogen kiln under stirring state, and control the reaction temperature at 100 to 120°C Under the reaction, measure the acid value every half an hour until the acid value drops below 12mgKOH / g, cool the reaction product to about 70°C and add 755g of polyurethane prepolymer prepared by the above steps, keep the reaction temperature at 70°C, Add 3.5g of dibutyltin dilaurate, measure the isocyanate content every half an hour, until the isocyanate content is zero as the reaction end point, add ...

Embodiment 2

[0065] Put 3000g polyethylene glycol 1000, 2835g diphenylmethane diisocyanate, 1.5g dibutyltin dilaurate into the stirred reactor, keep the reaction temperature at about 75°C, measure the isocyanate content every half hour until the isocyanate content is 5.6% was the end point of the reaction. In another stirred reactor, add 1850gE-51 bisphenol A epoxy resin, 860g methacrylic acid, 10.84g benzyldimethylamine, 1.084g hydroquinone, the reaction temperature is controlled at 100~120°C, every Measure the acid value once half an hour until the acid value drops below 12mgKOH / g as the end point of the reaction, cool the reaction product to about 70°C, add 797g of polyurethane prepolymer, add 4g of dibutyltin dilaurate, control the reaction temperature at 70°C, Measure the isocyanate group content every half hour until the isocyanate content is 0 and reach the end of the reaction, add 2000g styrene and 350g methyl methacrylate, and stir evenly to obtain a toughened modified vinyl ester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com