Hydrostatic pressure test machine

A technology of hydrostatic pressure and testing machine, which is applied in the direction of applying stable tension/pressure to test material strength, testing of mechanical components, testing of machine/structural components, etc., and can solve the problem of poor versatility of hydrostatic testing machines, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

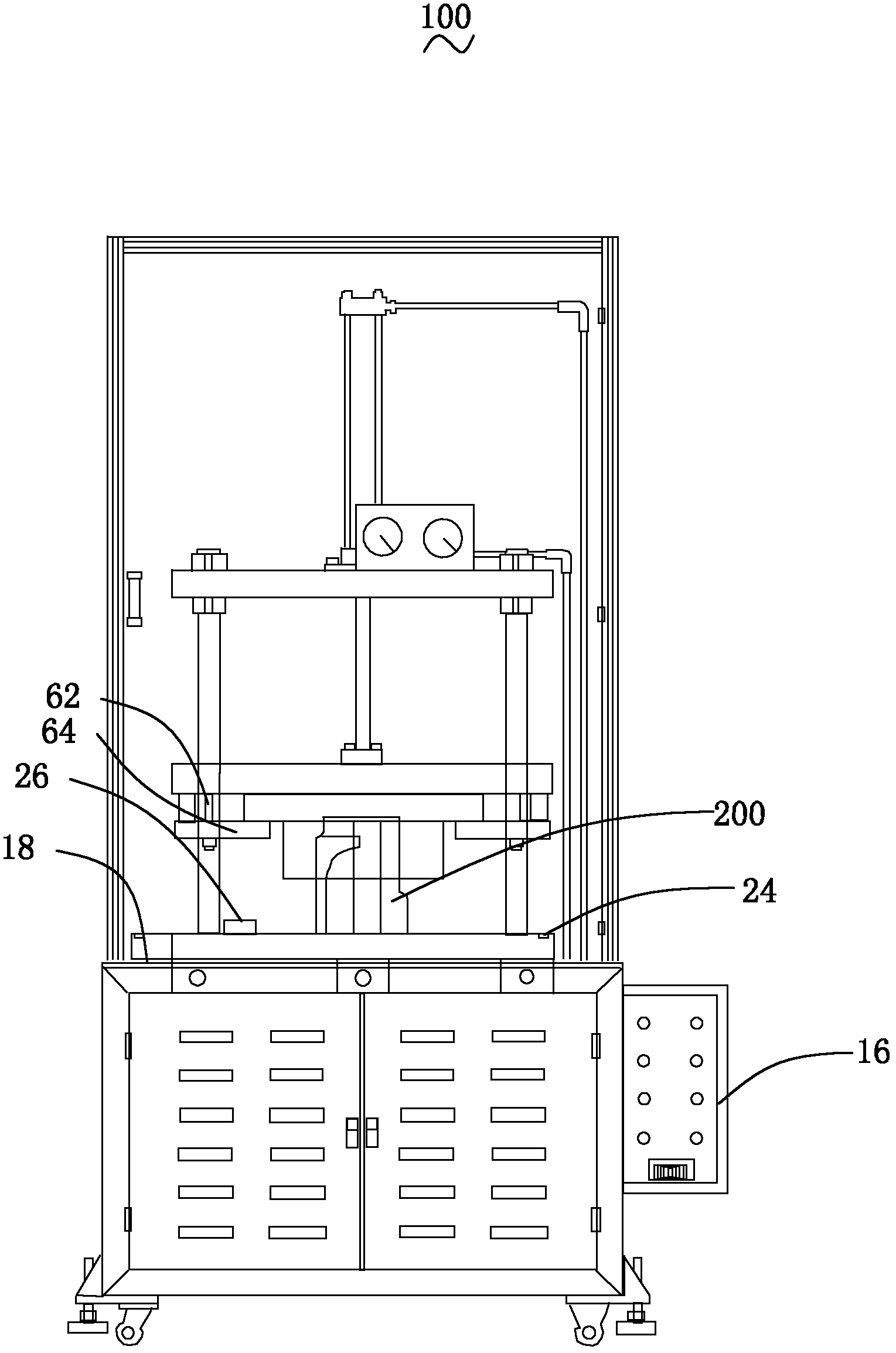

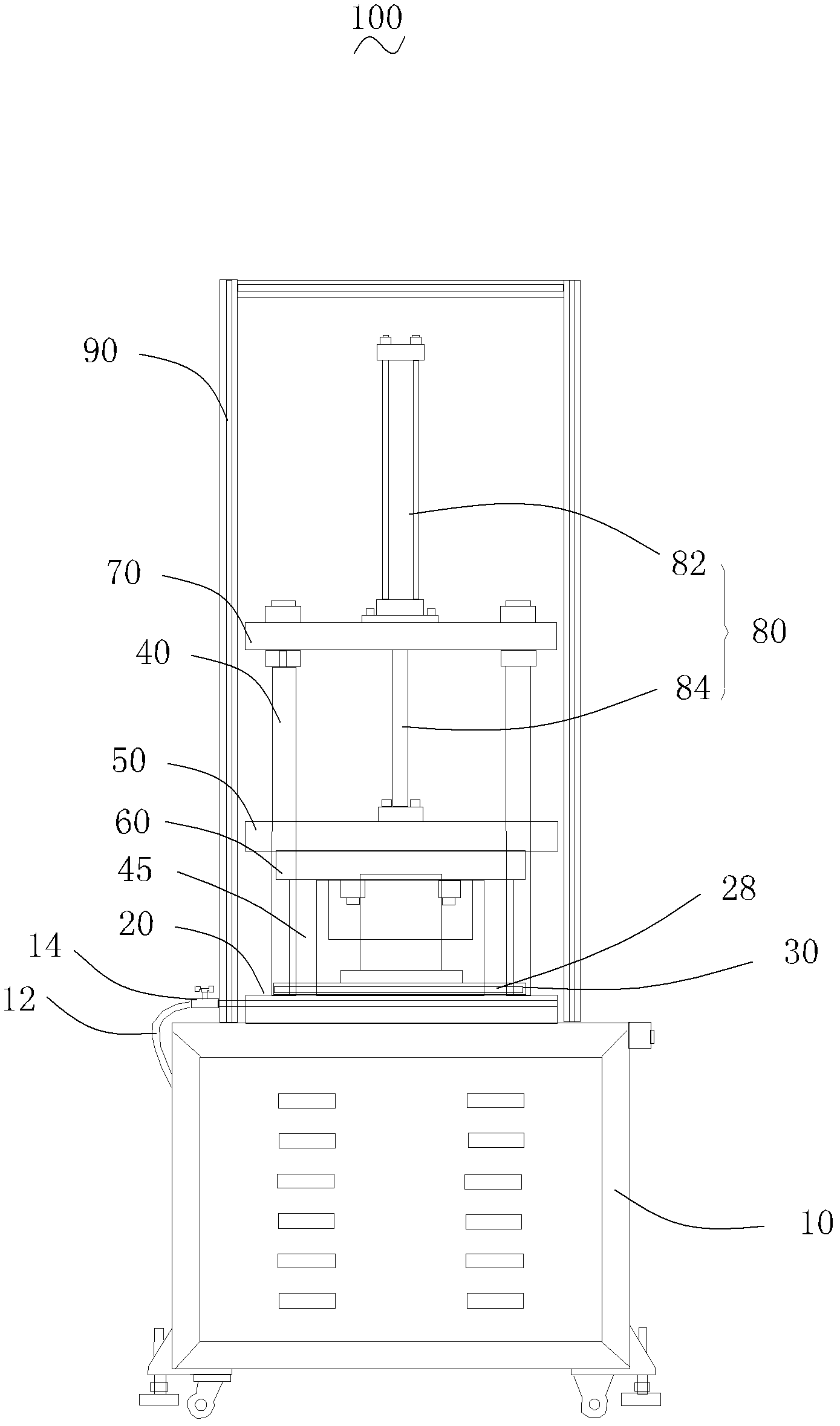

[0017] The lamps will be further clarified below in conjunction with the accompanying drawings and specific embodiments.

[0018] Please also see figure 1 and figure 2 , The hydrostatic pressure testing machine 100 of an embodiment is used for performing hydrostatic pressure test on the workpiece 200, and the workpiece 200 is the casing of electrical equipment, which has an opening (not shown in the figure). The hydrostatic testing machine 100 includes an operating platform 20 , a guide 40 , a pressing member 50 and a driving member 80 . A water inlet hole (not shown) is opened in the middle of the operation platform 20 . A first positioning member 26 and a second positioning member 28 are also provided on the operating platform 20 . The first positioning member 26 is slidable relative to the operating platform 20 along a first direction, and the second positioning member 28 is slidable relative to the operating platform 20 along a second direction perpendicular to the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com