Pre-service hydrostatic test integrated system on secondary side of steam generator

A steam generator and hydraulic test technology, which is applied in nuclear power generation, nuclear reactor monitoring, and reactors, etc., can solve the problems of poor safety of the suppression system, many temporary interfaces on site, and many test operators, so as to shorten the test period and reduce the volume. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

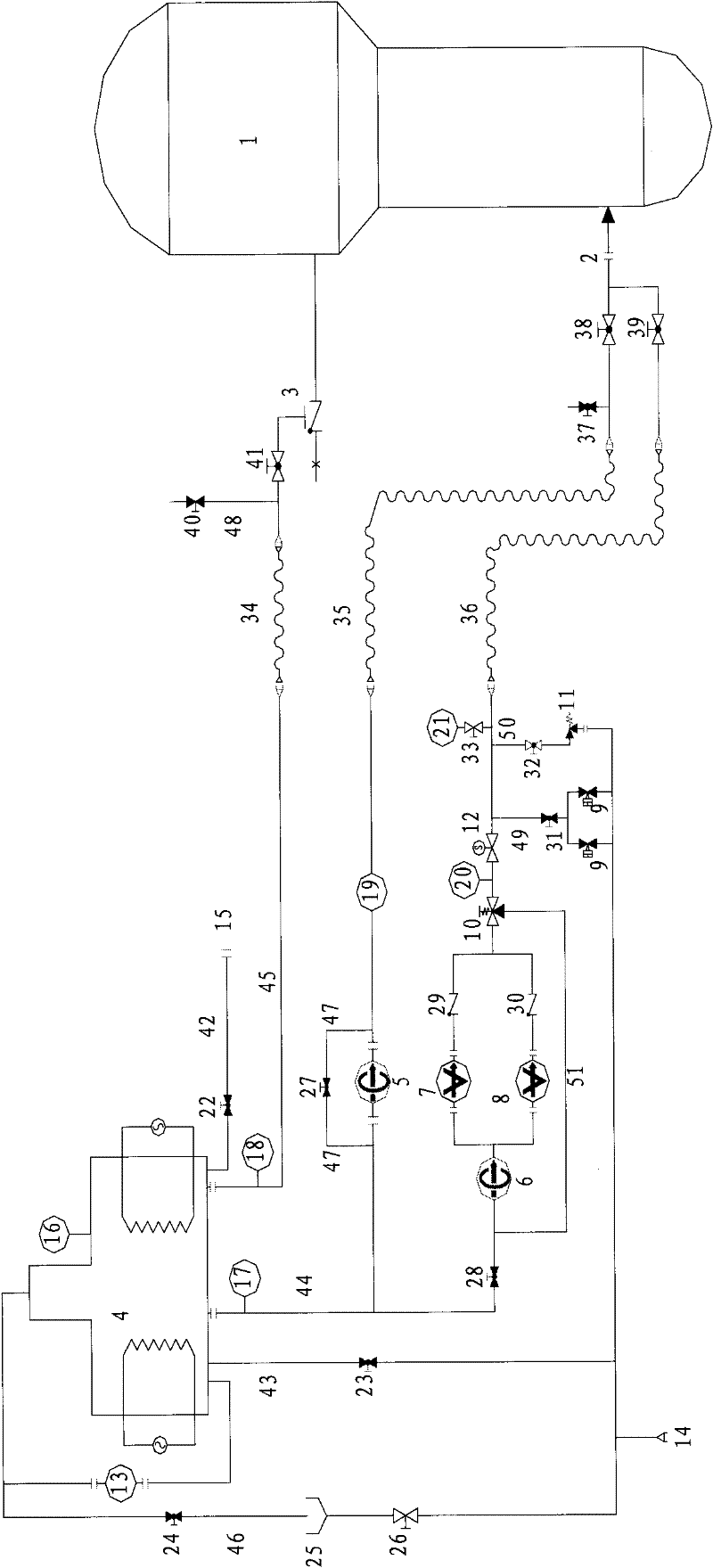

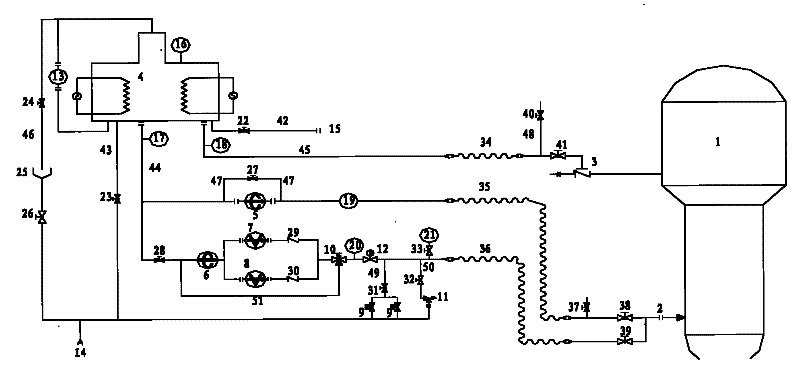

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0015] Such as figure 1 As shown in the figure, an integrated system for hydraulic pressure test before the secondary side of the steam generator in the PWR nuclear power plant includes a high power density electric heating water tank 4, a circulation pump 5, a front booster pump 6, and a large flow pressure pump 7 , small flow pressure pump 8, bypass pressure relief regulating valve 9, adjustable pressure return device 10, pressure outlet safety valve 11, pressure outlet solenoid valve 12, heating water tank level gauge 13, system drainage interface 14, system water replenishment interface 15 , water tank thermometer 16, water tank outlet thermometer 17, water tank return water thermometer 18, heating circulation flow meter 19, pressure gauge at the pressure outlet 20, local pressure gauge 21 at the pressure outlet, water tank replenishment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com