Intelligent high-temperature high-voltage experimental instrument for dynamic leak stopping evaluation

A high-temperature, high-pressure, dynamic technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of not being able to truly simulate the actual situation of leakage formations, unreasonable positions, and inability to perform simultaneously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

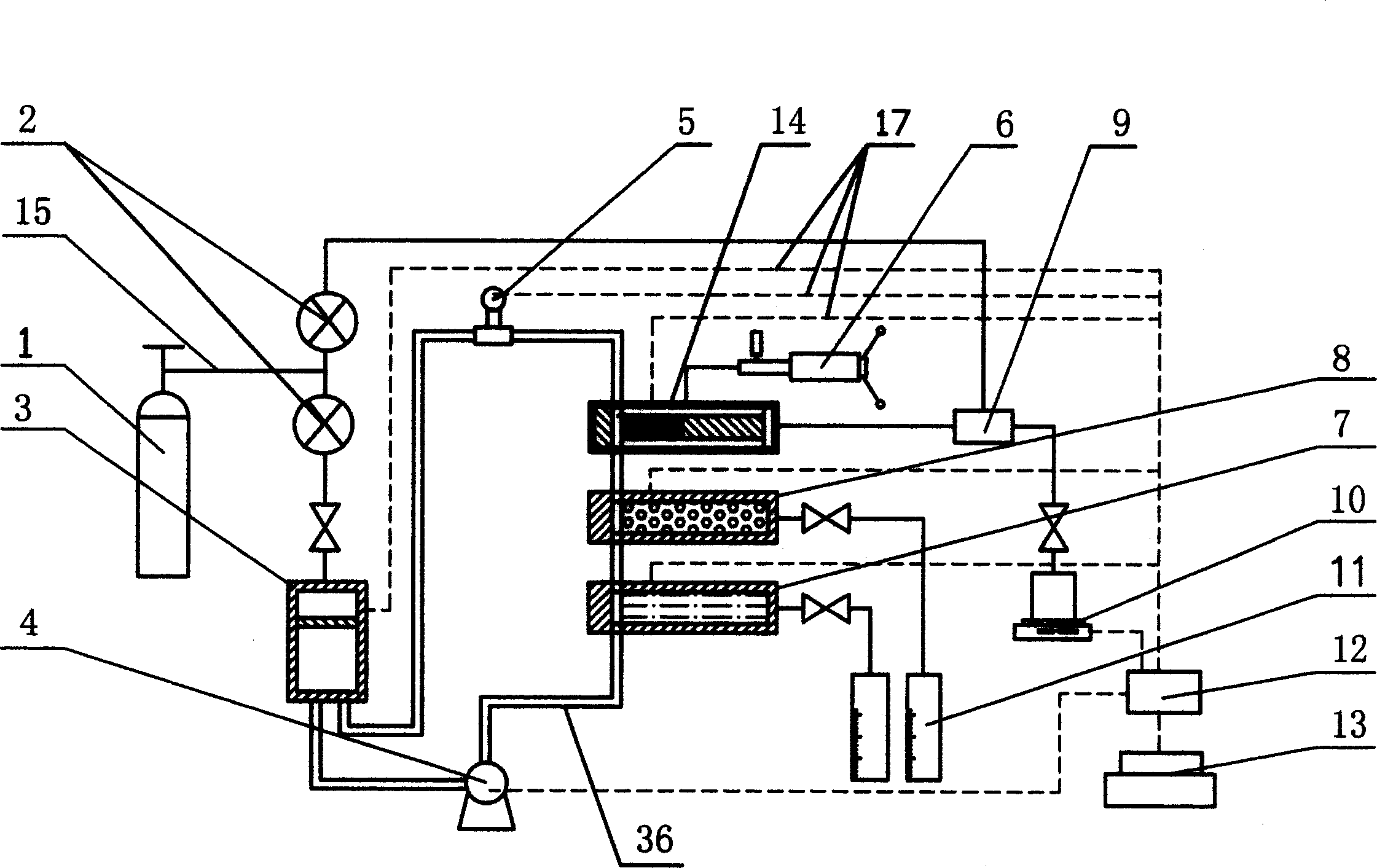

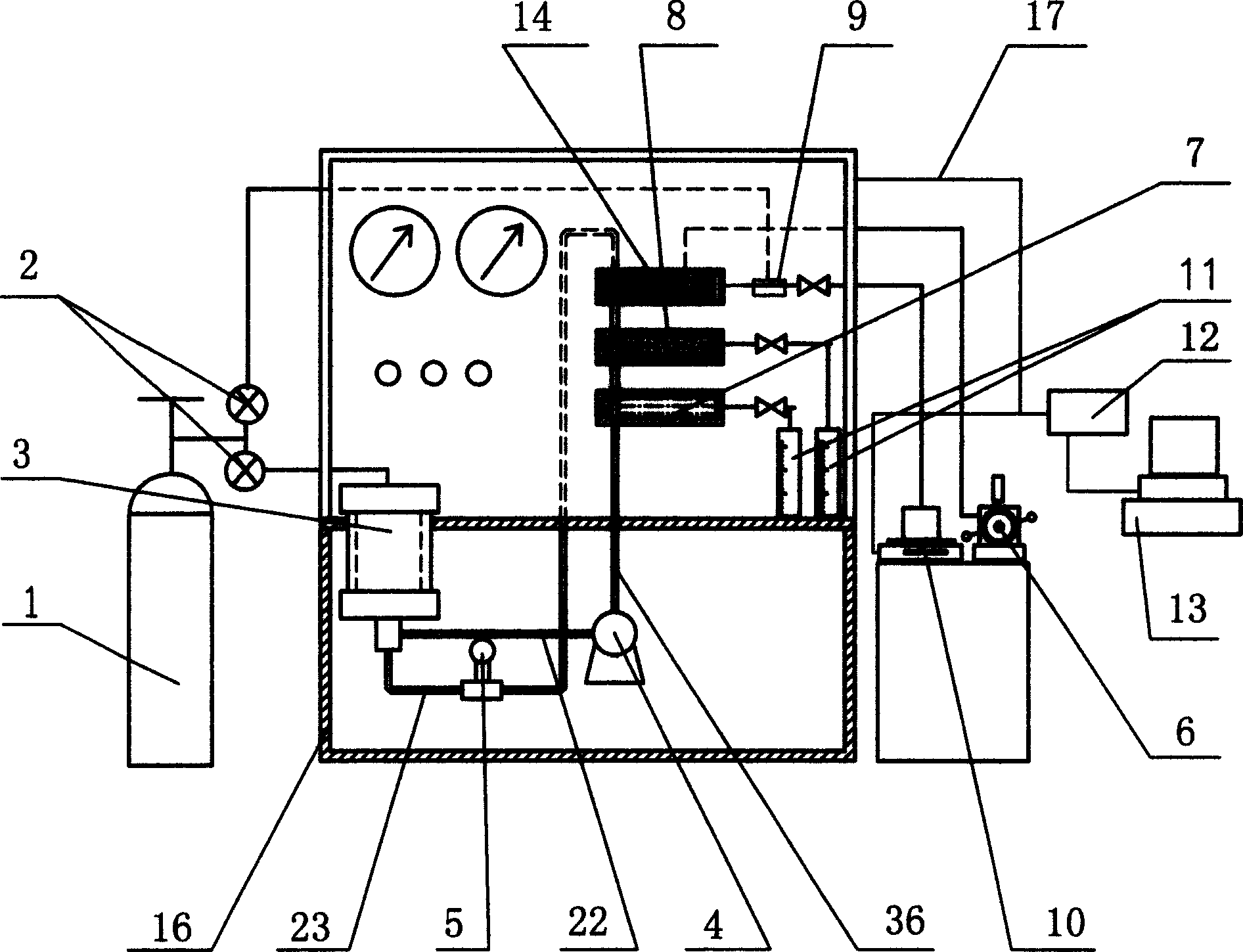

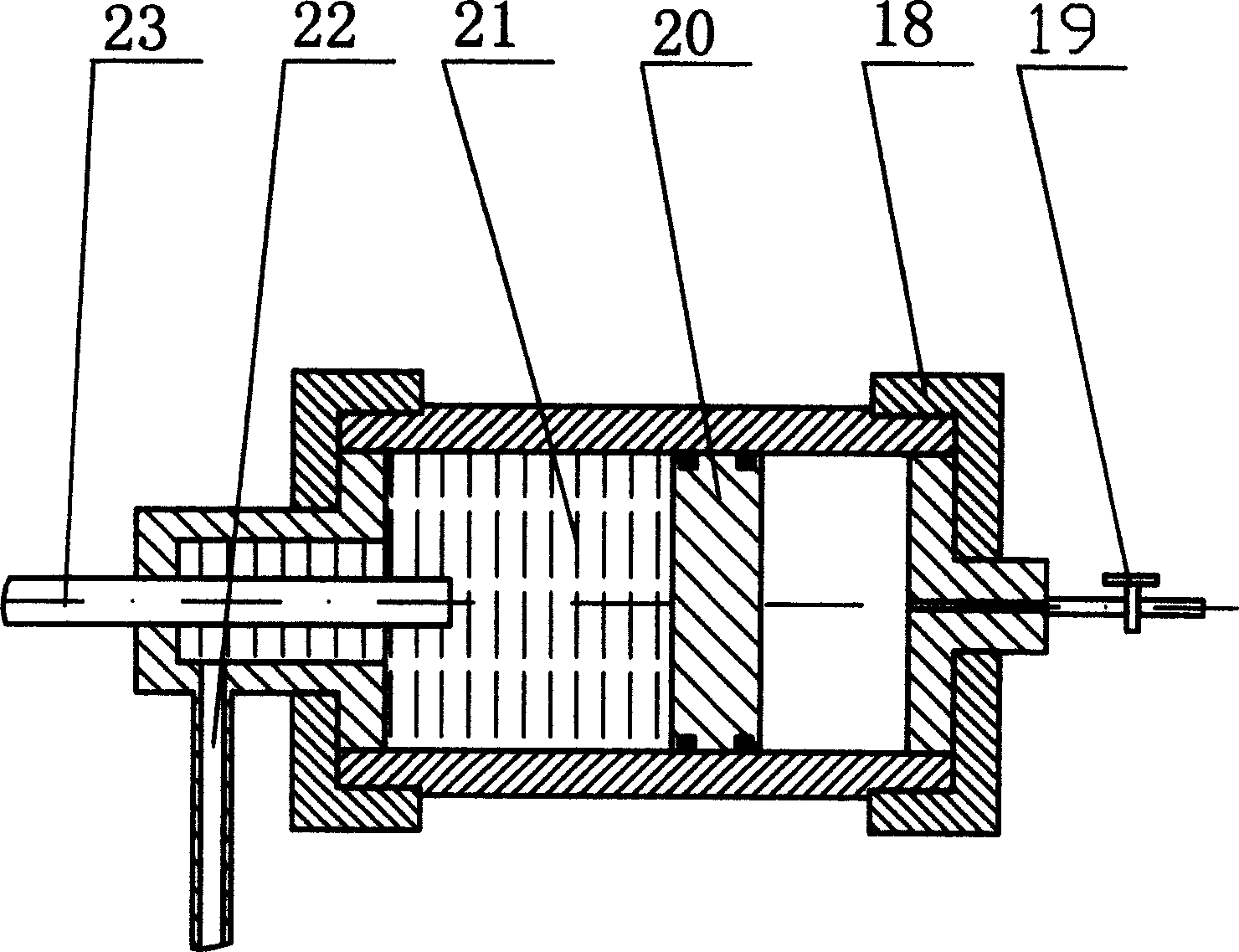

[0015] The intelligent high-temperature and high-pressure dynamic plugging evaluation experimental instrument consists of air source 1, high-pressure relief valve 2, piston type high-temperature and high-pressure mud tank 3, mud pump 4, flow meter 5, ring pressure pump 6, slotted plate holder 7, steel ball Leaking bed holder 8, back pressure controller 9, electronic balance 10, glass measuring cylinder 11, data collector 12, computer and printer 13, core holder 14, gas pressurized pipeline 15, shell 16, control line 17 , Gland 18, valve 19, piston 20, outer sleeve 22, inner casing 23, core fixing rod 24, mud channel 25, rubber cylinder 26, core 27, core adjusting rod 28, ring pressure inlet 29, seam plate 30, The slit plate adjusting rod 31, the mud outlet valve 32, the steel ball 33, the steel ball baffle 34, the baffle adjusting rod 35, and the liquid circulation pipeline 36 are composed.

[0016] In the experiment, man-made or natural core 27 is installed in the core holder 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com