In-line water tightness testing device for elastic sealing gasket of shield tunnel

An elastic sealing gasket and shield tunneling technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness and applying stable tension/pressure to test the strength of materials, etc., can solve the difficult and unsatisfactory verification of the waterproof ability of sealing gaskets Issues such as the requirements for the quality inspection of shield tunnel gasket quality, to achieve the effect of an accurate evaluation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

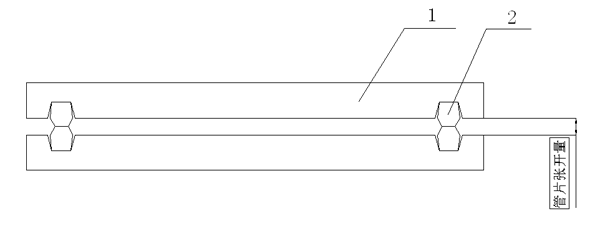

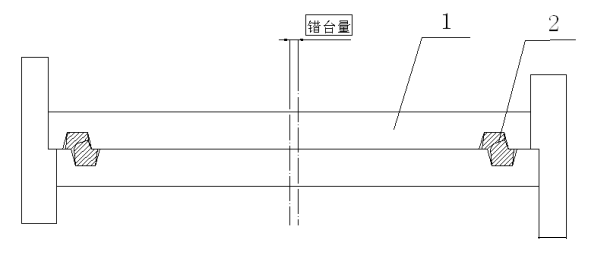

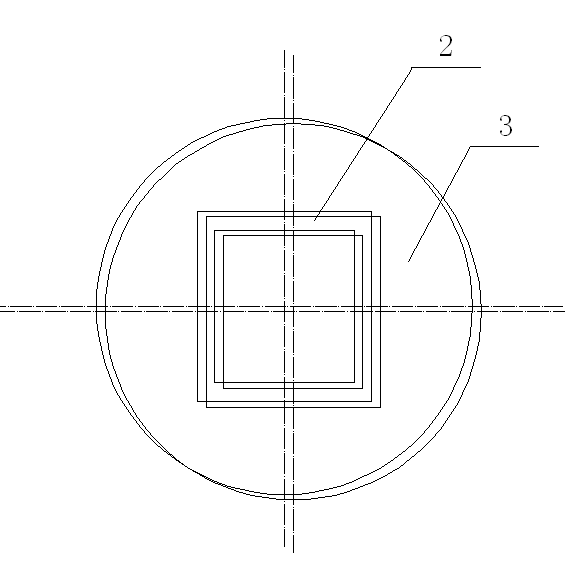

[0027] attached Figure 1-12 The middle marks 1-15 represent segment 1, elastic gasket 2, circular profile cover plate 3, rectangular profile cover plate 4, gasket 5, limit plate bolt hole 6, leg 7, lower cover plate 8, Rectangular groove 9, bolt (hole) 10, water inlet hole 11, upper cover plate 12, air outlet hole 13, water pressure gauge screw hole 14, limit plate 15.

[0028] During the design process of the gasket, there is no suitable theoretical guidance. Therefore, it belongs to empirical design, and in the production process, its production quality can only be controlled by simple calipers and hardness testers for shape and hardness. It is impossible to actually simulate the waterproof actual situation under its working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com