Method for testing and evaluating anti-loosening performance of bolt connection pair

An evaluation method and connection pair technology, applied in the field of mechanical assembly, can solve the problem of inability to test the anti-loosening performance, and achieve the effect of improving the anti-loosening performance and reliability, objective test results, and perfect and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

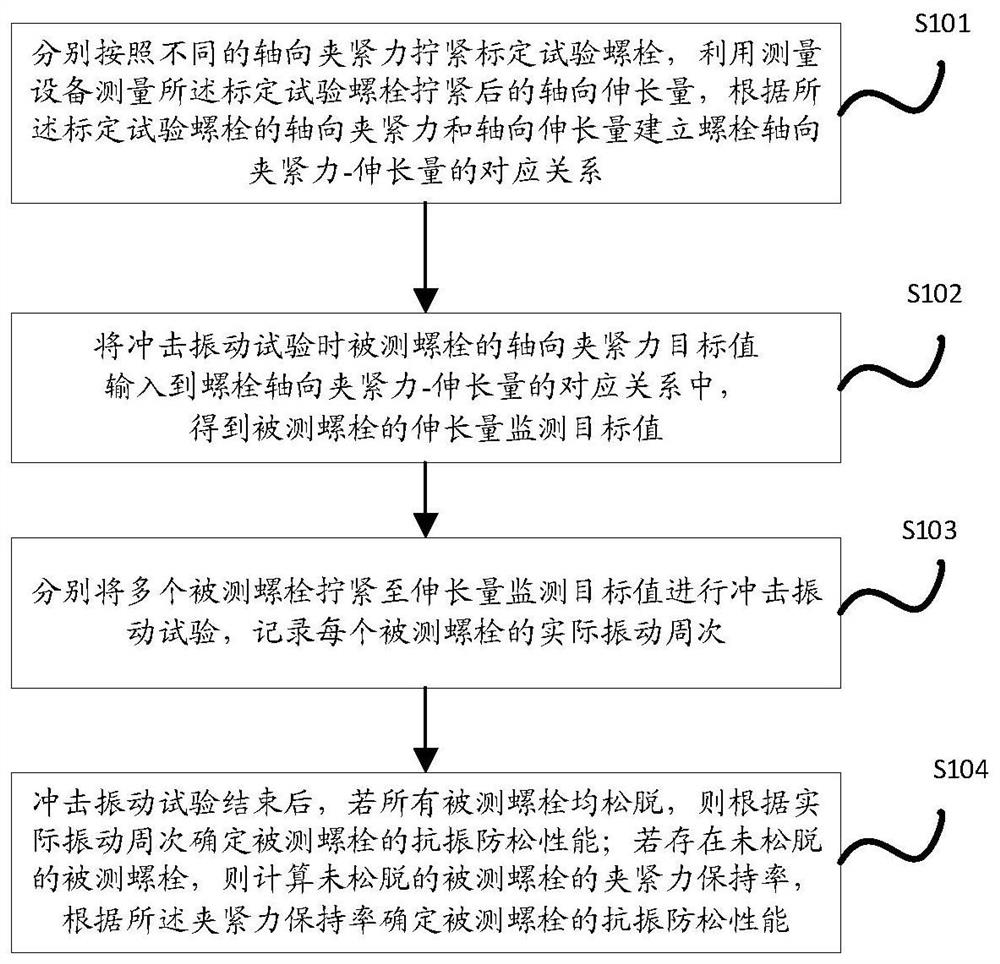

[0044] Embodiment 1 of the present application provides a method for testing and evaluating the anti-loosening performance of a bolted joint, comprising the following steps:

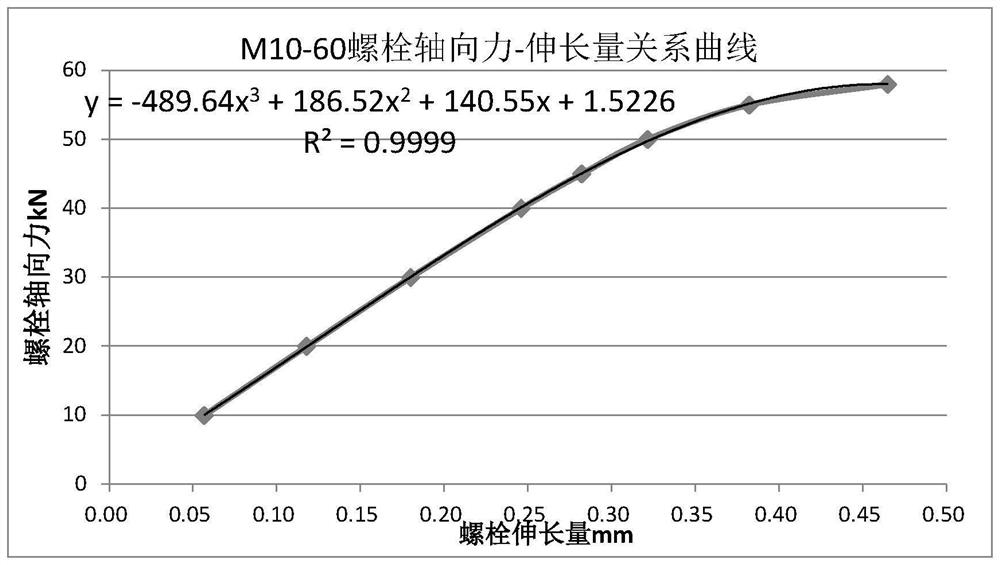

[0045] Step S101, on the bolt tightening performance testing machine, tighten the calibration test bolts sequentially according to different axial clamping forces, use an ultrasonic measuring instrument to measure the axial elongation of the calibration test bolts after tightening, and according to the axial clamping force of the calibration test bolts The corresponding relationship between the bolt axial clamping force and the elongation is established by the tightening force and the measured axial elongation, and the corresponding relationship curve between the obtained bolt axial clamping force and elongation is as follows image 3 as shown, image 3 In , the relationship between bolt axial clamping force-elongation can be expressed as: y=-489.64x 3 +186.52x 2 +140.55x+1.5226, where, y represents th...

Embodiment 2

[0050] Embodiment 2 of the present application provides a method for testing and evaluating the anti-loosening performance of a bolted joint, comprising the following steps:

[0051] Step S101, on the bolt tightening performance testing machine, tighten the calibration test bolts sequentially according to different axial clamping forces, use an ultrasonic measuring instrument to measure the axial elongation of the calibration test bolts after tightening, and according to the axial clamping force of the calibration test bolts Tightening force and measured axial elongation establish the corresponding relationship of bolt axial clamping force-elongation, and the corresponding relationship curve diagram of the obtained bolt axial clamping force-elongation is the same as embodiment 1; this implementation In the example, the calibration test bolt is a bolt with a diameter of 10mm and a length of 60mm, and the number can be set to five;

[0052] Step S102, it is known that the target...

Embodiment 3

[0056] Embodiment 3 of the present application provides a method for testing and evaluating the anti-loosening performance of a bolted joint, comprising the following steps:

[0057] Step S101, on the bolt tightening performance testing machine, tighten the calibration test bolts sequentially according to different axial clamping forces, use an ultrasonic measuring instrument to measure the axial elongation of the calibration test bolts after tightening, and according to the axial clamping force of the calibration test bolts Tightening force and measured axial elongation establish the corresponding relationship of bolt axial clamping force-elongation, and the corresponding relationship curve diagram of the obtained bolt axial clamping force-elongation is the same as embodiment 1; this implementation In the example, the calibration test bolt is a bolt with a diameter of 10mm and a length of 60mm, and the number can be set to five;

[0058] Step S102, it is known that the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com