Evaluation testing method for damage of drilling fluid to compact gas reservoir

An experimental method and drilling fluid technology, applied in the direction of material inspection, suspension and porous material analysis, analysis by nuclear magnetic resonance, etc., can solve the problem of strong heterogeneity of core, loss of core thickness, poor repeatability and reproducibility of experiments, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

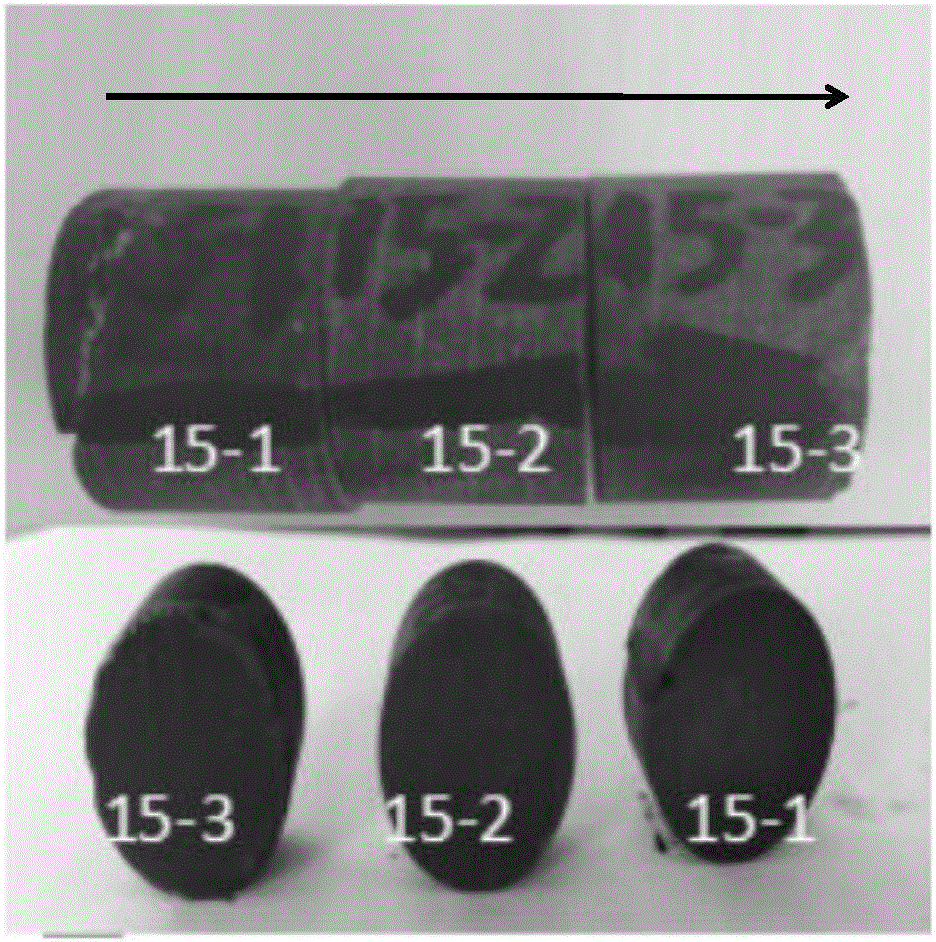

[0074] Taking the tight sandstone core of the Kelasu gas field as an example, according to the well test data, the original water saturation of the reservoir S wi 25-35%. Select 6 tight sandstone cores and use the method of the invention to evaluate the damage degree of drilling fluid invasion. Here, No. 15 core sample is adopted as the experimental object, and the experimental method for evaluating the damage of drilling fluid in tight gas reservoirs provided by the present invention comprises the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com