Frictional resistance calibrating device aiming at liquid crystal coating

A technology of liquid crystal coating and frictional resistance, which is applied in the field of frictional resistance calibration devices, can solve the problems of not meeting the test accuracy requirements, not easy to control, complicated methods, etc., and achieve simple structure, easy adjustment, and easy acquisition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

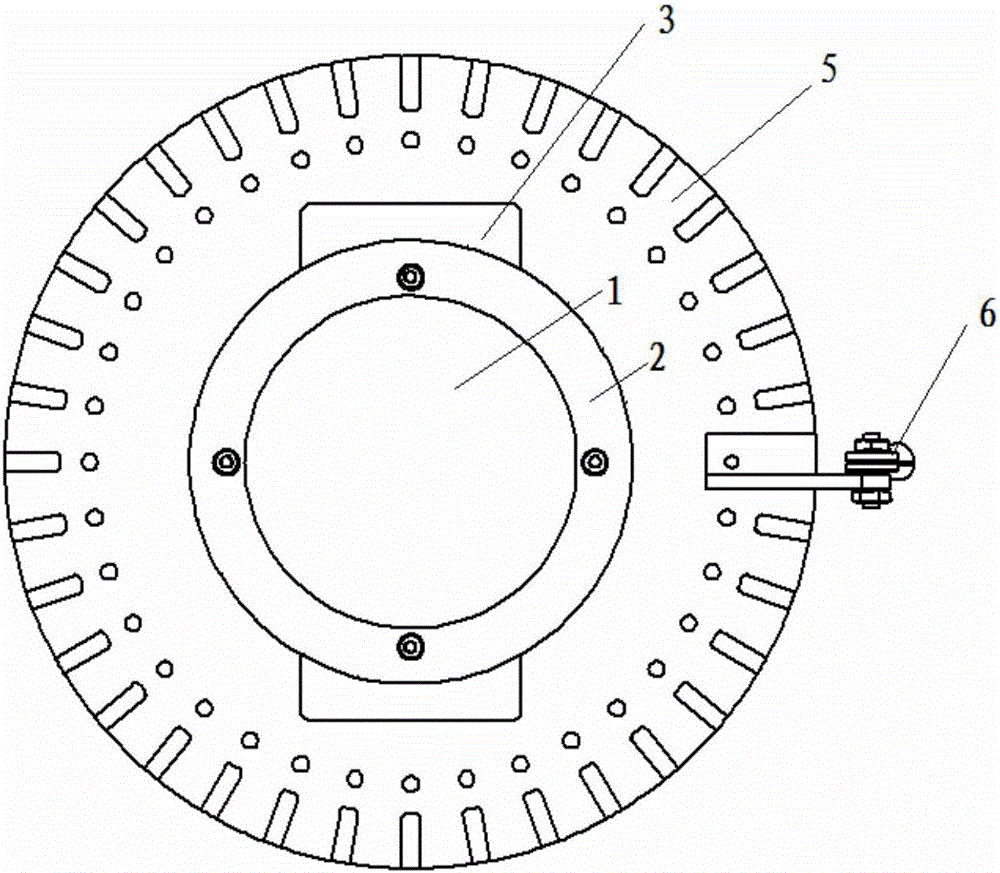

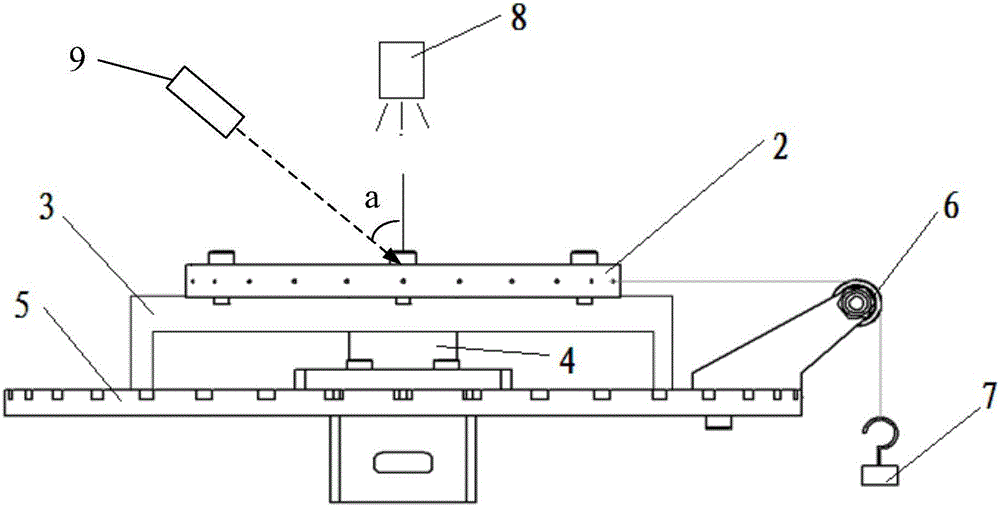

[0022] The static friction force is used as the standard input required for calibration, so as to observe the response of the sensing element—the liquid crystal coating—to the friction force, and obtain the required calibration data. Liquid crystal coating is a material sensitive to shear force. When subjected to shear force, the wavelength of light reflected by the liquid crystal to the outside world will change, allowing people to observe the color change of the liquid crystal. The largest color change can be observed in the direction of . Therefore, a piece of glass can be placed on the surface of the liquid crystal coating, and the glass is in direct contact with the liquid crystal coating, and the weight is passed through the fixed pulley to apply a lateral pulling force (not greater than the maximum static friction force) to it. In the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com