Coal mine intrinsic safety type camera device capable of automatically cleaning camera window

A technology for automatic cleaning and camera devices, applied in cleaning methods and tools, cleaning methods using tools, image communication, etc., can solve problems such as inconvenience, affecting video surveillance effects, regular cleaning, etc., to achieve the effect of ensuring light transmission and easy disassembly , Improve the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

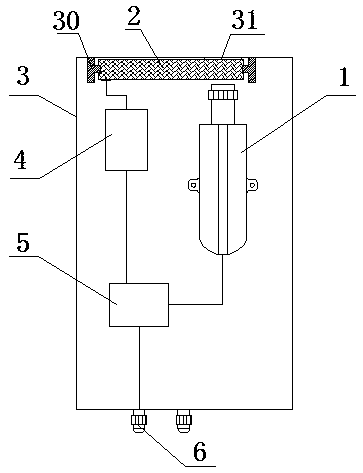

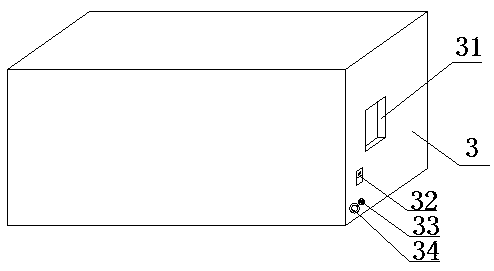

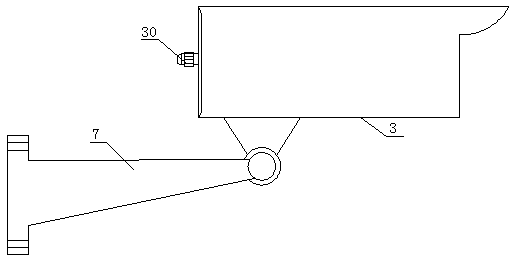

[0022] see figure 1 , figure 2 , image 3 , the present embodiment provides a coal mine intrinsically safe imaging device for automatically cleaning the imaging window, which is composed of a camera 1, an automatic cleaning mechanism 2, and a protective cover 3. The protective cover 3 is a box-type structure, and the front end plate of the protective cover 3 is arranged Camera port 31; camera 1 and automatic cleaning mechanism 2 are integrated in protective cover 3, and automatic cleaning mechanism 2 is between the camera head of camera 1 and the camera port 31 of protective cover 3, and control main board 4, Power supply module 5; The quick joint 6 of camera 1 signal transmission is installed on the rear end plate of protective cover 3, and the control switch 32 that is electrically connected with control mainboard 4 is installed on the front end pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com