Visible light assisted diamond chemical mechanical polishing solution and polishing method

A chemical-mechanical and visible light technology, applied in polishing compositions containing abrasives, grinding tools, etc., can solve the problems of low polishing efficiency, polluted environment, poor polishing quality, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

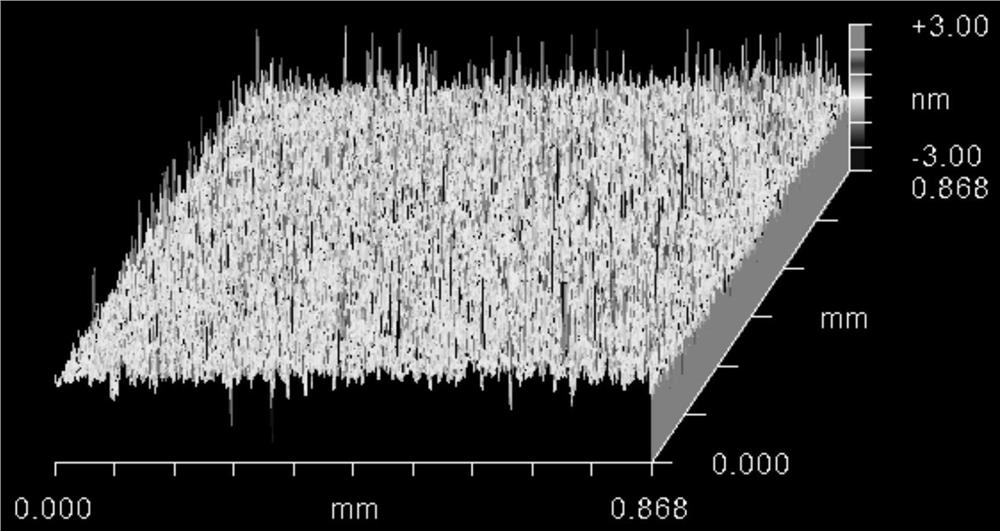

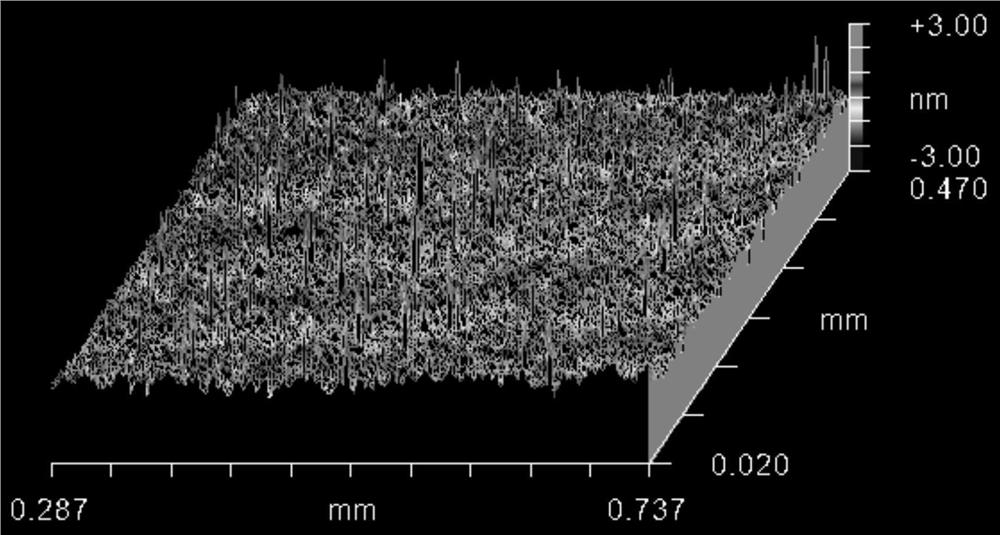

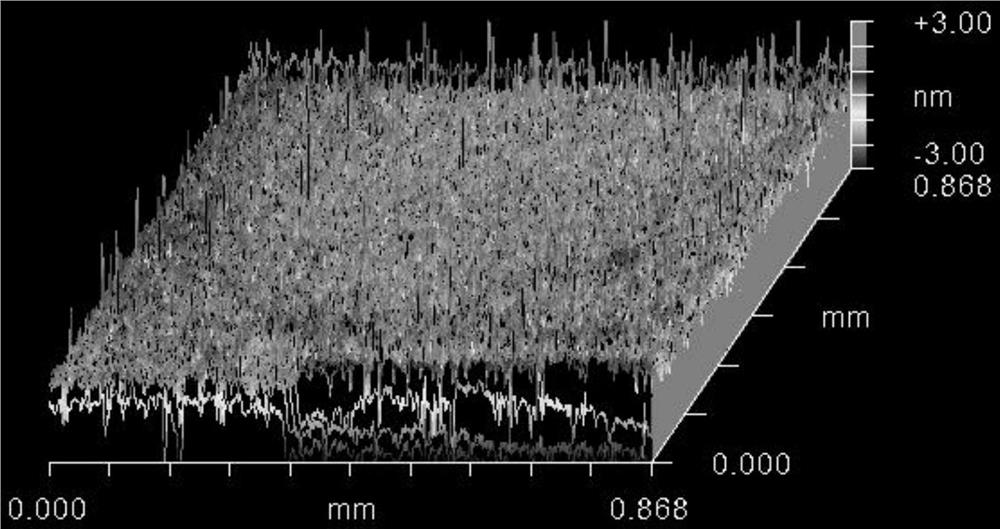

Image

Examples

Embodiment 1

[0023] 1) Prepare components A and B of polishing fluid. Among them, in component A: the concentration of hydrogen peroxide is 20wt%, the concentration of diamond powder is 0.06g / ml, the particle size is 0.5-1μm, and the weight percentage of deionized water is 74%. After mixing, stir evenly and oscillate in an ultrasonic device 10min. Among them, in component B: ZnO-Fe 2 o 3 The concentration is 0.1334g / l, oscillating in ultrasonic equipment for 10min.

[0024] 2) Use the size , Surface roughness Ra10nm glass disk as a polishing disk, rinse with deionized water before polishing.

[0025] 3) Place a 100w incandescent light bulb on a bracket at 15cm directly above the polishing disc. Under the irradiation of a visible light source, components A and B of the polishing solution are added dropwise at the same time to perform chemical mechanical polishing on the single crystal diamond crystal; the polishing equipment is an automatic pressure Grinding and polishing machine, set...

Embodiment 2

[0028] 1) Prepare components A and B of polishing fluid. Among them, in component A: the concentration of hydrogen peroxide is 15wt%, the concentration of diamond micropowder is 0.04g / ml, the particle size is 0-0.25μm, and the weight percentage of deionized water is 81%. Shake for 10 minutes. Wherein, in component B: the concentration of titanium dioxide-doped nano-diamond is 0.02667g / l, and it is vibrated in an ultrasonic device for 10 minutes.

[0029] 2) Use the size , Surface roughness Ra10nm glass disk as a polishing disk, rinse with deionized water before polishing.

[0030] 3) Place a 100w incandescent light bulb on a stand 10cm directly above the polishing disc. Under the irradiation of a visible light source, components A and B of the polishing solution are added dropwise at the same time to chemically mechanically polish the single crystal diamond crystal; the polishing equipment is an automatic pressure Grinding and polishing machine, set the polishing pressure ...

Embodiment 3

[0033] 1) Prepare components A and B of polishing fluid. Among them, in component A: the concentration of hydrogen peroxide is 25wt%, the concentration of diamond powder is 0.08g / ml, the particle size is 1-3μm, and the weight percentage of deionized water is 67%. After mixing, stir evenly and oscillate in an ultrasonic device 10min. Among them, in component B: the concentration of copper-iron hydrotalcite doped with nano-diamond is 0.2667g / l, and it is shaken in an ultrasonic device for 10 minutes.

[0034] 2) Use the size , Surface roughness Ra10nm glass disk as a polishing disk, rinse with deionized water before polishing.

[0035] 3) Place a 100w incandescent light bulb on a stand 20cm directly above the polishing disc. Under the irradiation of a visible light source, components A and B of the polishing solution are added dropwise at the same time to chemically mechanically polish the single crystal diamond crystal; the polishing equipment is an automatic pressure Grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com