Friction experiment table for initiatively regulating and controlling thickness of lubricating film between friction pair

A technology of lubrication test bench and friction pair, which is applied in the field of mechanical friction to achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

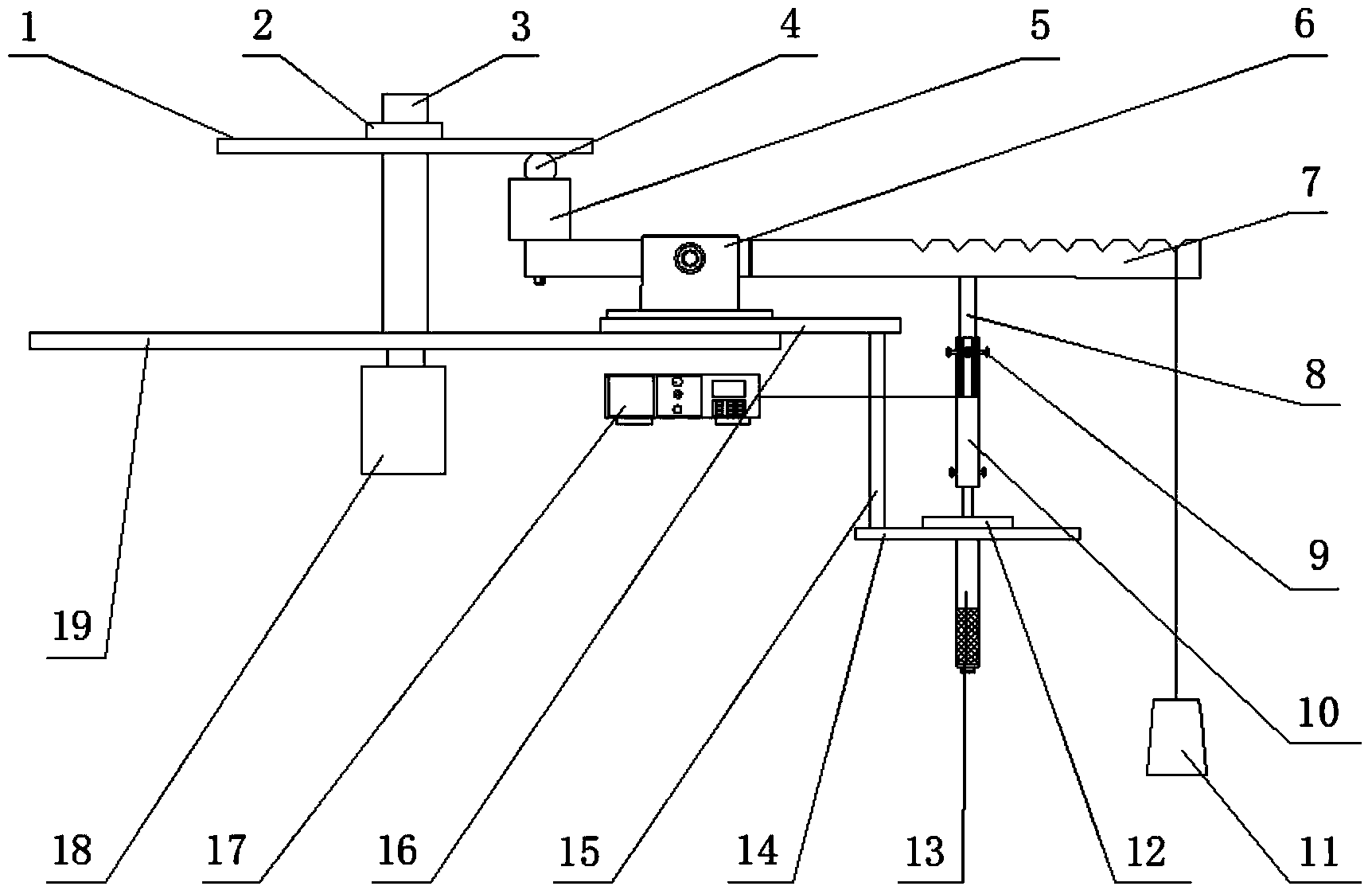

[0010] The friction test bench that actively regulates the thickness of the lubricating film between the friction pairs proposed by the present invention has a structure such as figure 1 As shown, it includes a lubrication test bench 19, a glass disc 1, a motor 18, a rotating shaft 3, a steel ball 4, an oil cup 5, a hinge 6, a lever 7 and a piezoelectric ceramic rod 8, and the motor is connected to a power supply (not shown in the figure) , the rotating shaft 3 is linked with the output shaft of the motor 18, the output shaft 18 passes through the lubrication test bench 19, the glass disc 1 is fixed on the upper end of the rotating shaft 3 by the fixing screw 2, and the glass disc 1 is linked with the rotating shaft 3. The hinge 6 is placed on the lubrication test bench 19, the lever 7 passes through the hinge 6, the oil cup 5 is placed on one end of the lever 7, and the weight 11 is hung on the other end of the lever 7. The steel ball 4 is placed between the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com