Rack

a technology of glass discs and racks, which is applied in the field of racks, can solve the problems of poor quality of optical disc masters, difficult to insert glass discs into semi-cylinders without scratching, and achieve the effect of easy hand-held inserting and easy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

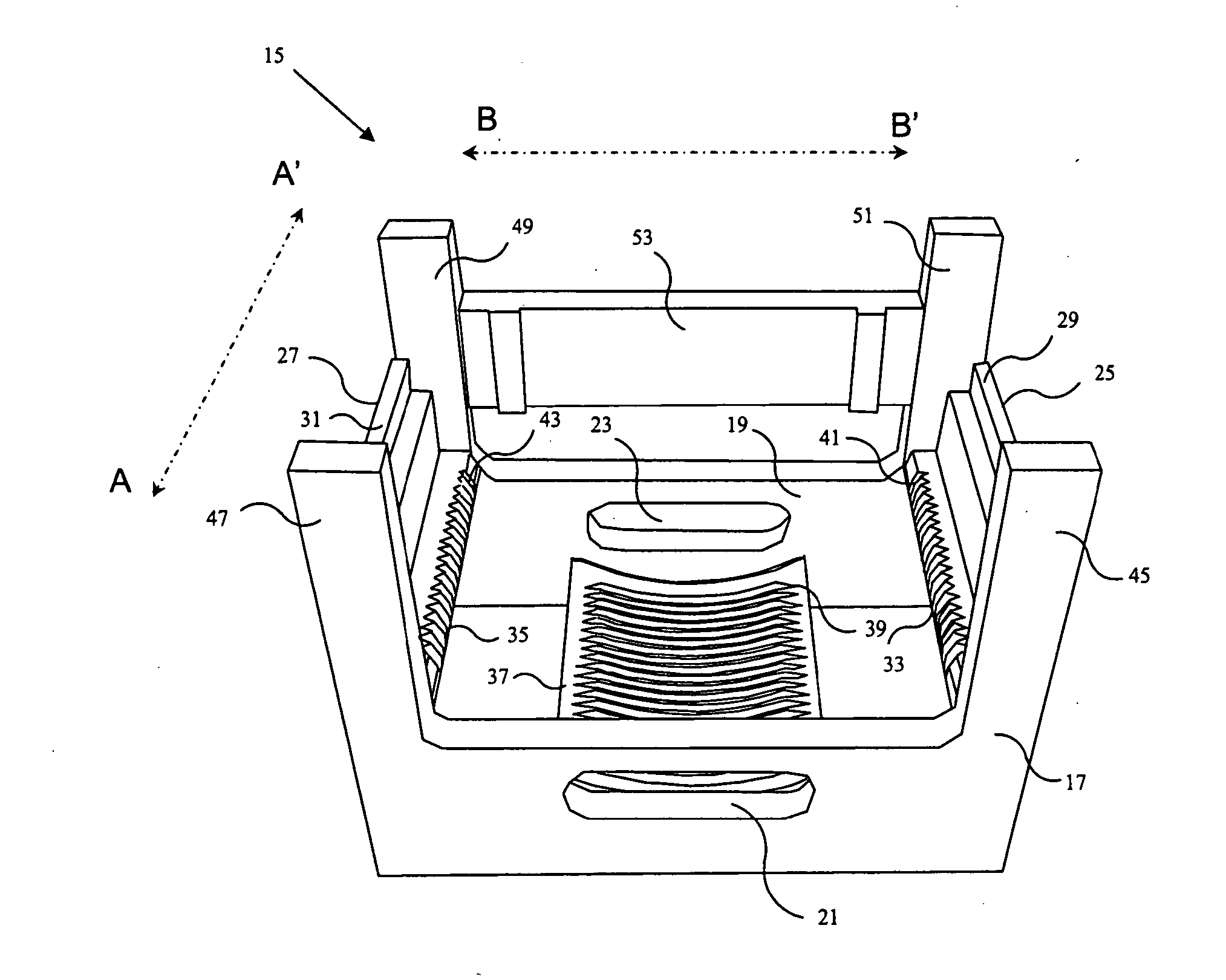

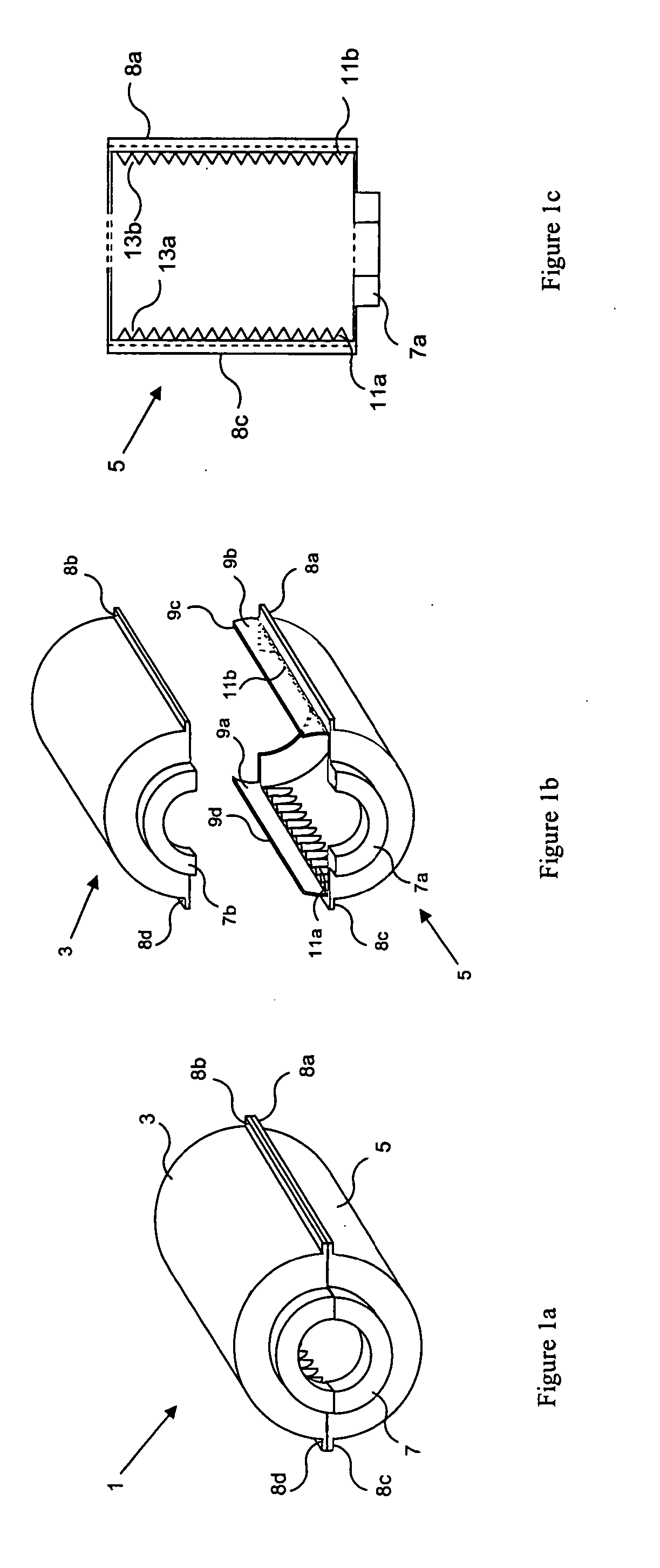

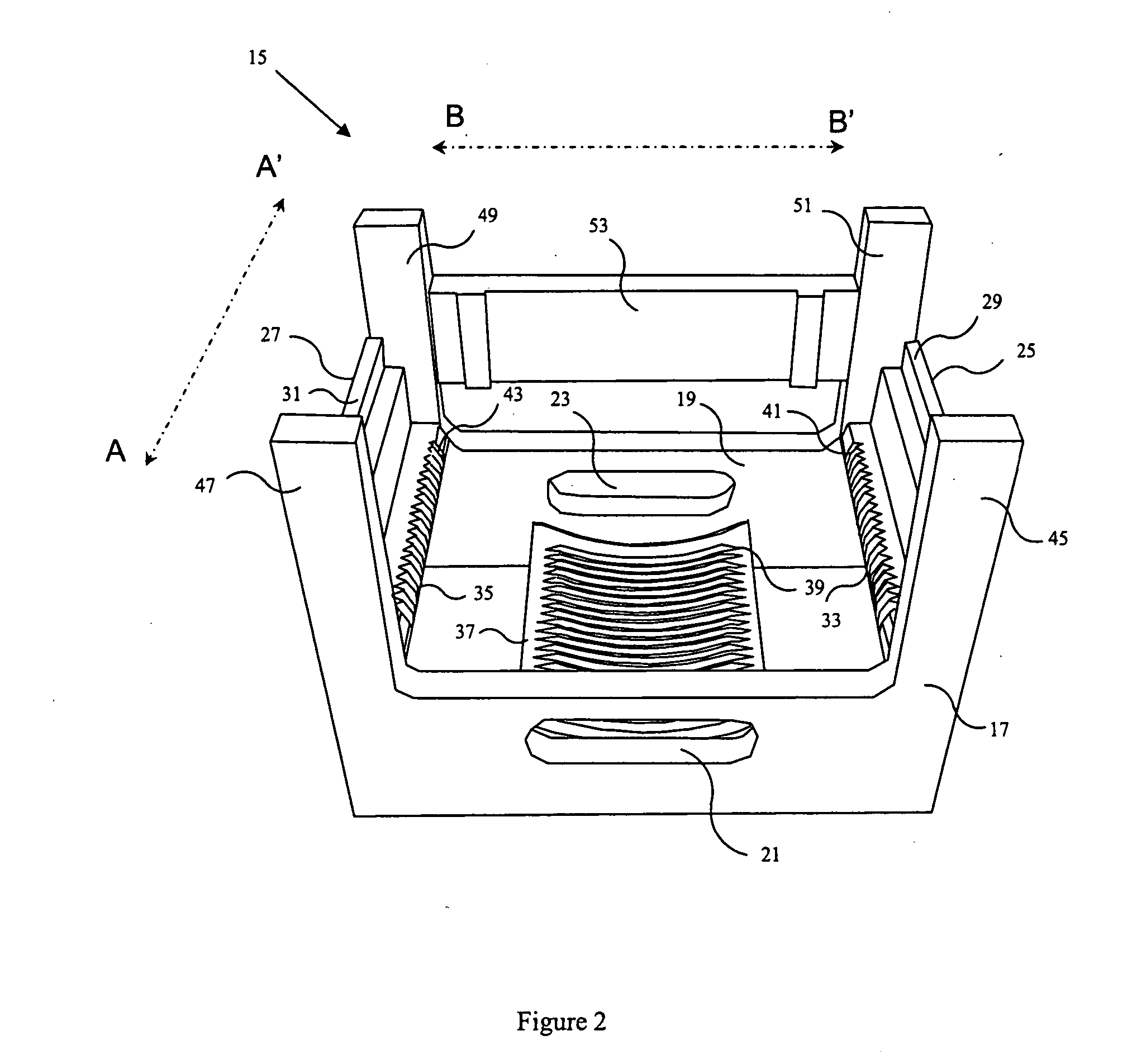

[0030]FIG. 1 shows a conventional storage barrel 1 consisting of two hollow storage semi-cylinders 3 and 5. The semi-cylinders 3 and 5 engage and discs slotted inside the barrel are protected from damage whilst in transit. The barrel 1 is a standard size to fit into an optical disc mastering machine. The collar 7 is used to fit the barrel into the mastering machine in the correct orientation and is split into two halves, 7a and 7b. Running along the length of the rim on each storage semi-cylinder are flanges 8a, 8b, 8c and 8d. The storage semi-cylinder 5 has retaining strips 9a and 9b running down the length of each side which curve inwardly and follow the radius of curvature of the barrel. In use, the outer surfaces of the retaining strips face the inner surface of the storage semi-cylinder 3. There are no retaining strips on storage semi-cylinder 3. The retaining strips 9a and 9b are able to exert a compressive force on the edge of the discs and prevent excessive movement of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com