Glass disc cutting method

A cutting method and glass technology, which are applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems that the upper and lower drill bits are not coaxial, and the coaxial difficulties of the upper and lower drill bits are difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] figure 1 It is a schematic diagram of a fried edge glass disc. The edge of the glass disc shattered.

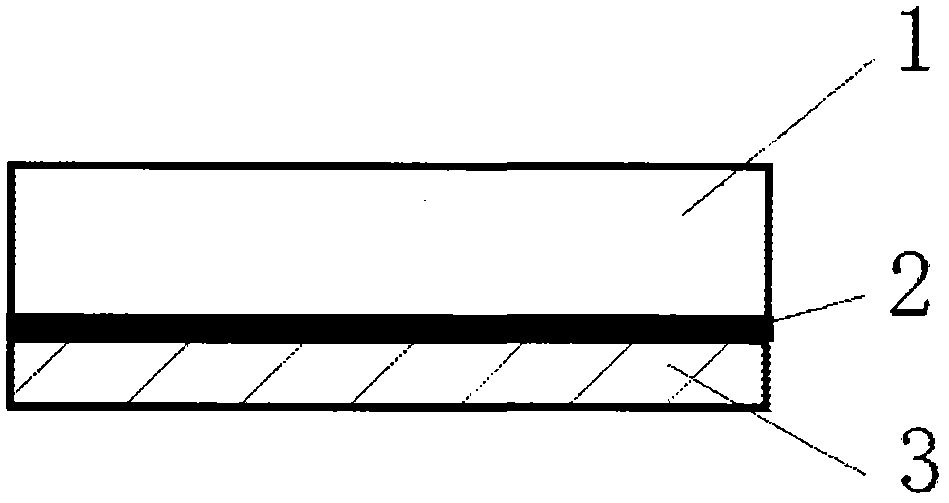

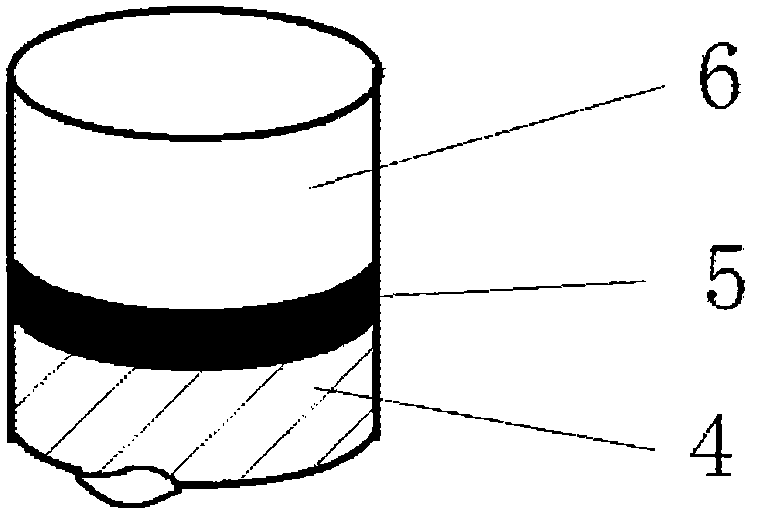

[0015] figure 2 It is a glass plate with a lower backing plate, which consists of a glass plate 1, an intermediate adhesive layer 2 and a lower backing plate 3, and what the lower backing plate 3 has used is a 3 mm thick common building glass plate. The glass plate is an ordinary building glass plate, and the glue is a good adhesive. Put the glued glass plate into the glass puncher to drill holes. The drill bit is a hollow drill bit. During the drilling process, the inner and outer sides of the hollow drill bit should be cooled with water. After drilling through the glass plate, the removed glass disc is as image 3 shown. It is composed of an upper glass disc 6, an intermediate adhesive layer 5 and a lower lining glass disc 4. The lower surface of the glass disc 6 is supported by the lining glass plate 3 and fixed by the adhesive layer 2 during the drilling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com