Electron beam evaporation technology based preparation method for ZnO high-transmittance and high-conductivity film

An electron beam evaporation, high transmittance technology, applied in vacuum evaporation coating, ion implantation coating, metal material coating process, etc. Low rate and other problems, to achieve the effect of low price, high stability, broad-spectrum transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

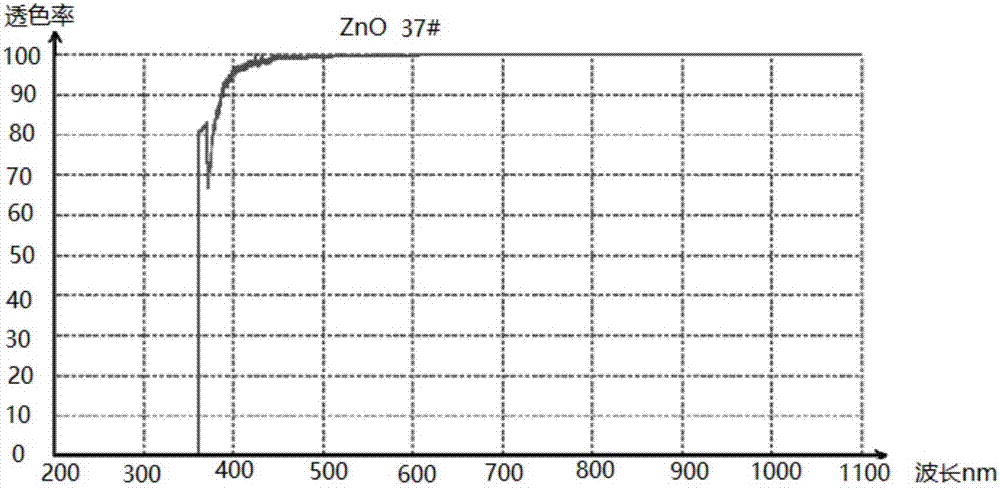

[0022] An embodiment of the present invention provides a method for preparing a ZnO thin film with high transmittance and high conductivity based on electron beam evaporation technology, including the following steps:

[0023] S1. Glass cleaning process

[0024] Place a certain size of glass on the bracket of the cleaning tank, use washing powder + detergent to scrub both sides of the glass with a sponge, after cleaning, rinse with tap water, then rinse with deionized water and dry naturally; place the glass on stainless steel Ultrasonic cleaning with acetone for 5 minutes on the hanger, and then ultrasonic cleaning with absolute ethanol for 5 minutes; ultrasonic cleaning with deionized water twice, 5 minutes each time. Put the washed glass into the oven to dry for later use.

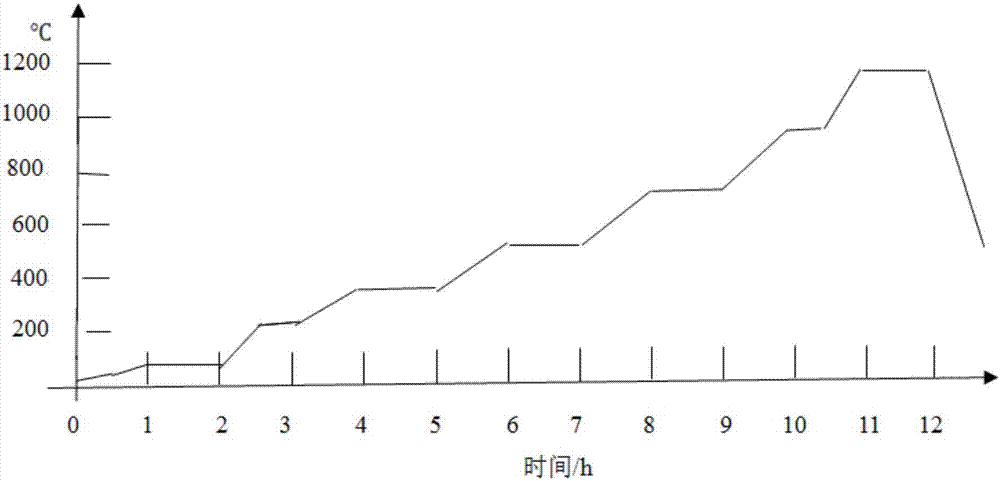

[0025] S2, ZnO target preparation process

[0026] Fill a mold with a diameter of 2.5 cm and a depth of 4 cm with ZnO powder, and vibrate slightly. Fill it up and pour it into a clean container, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com