Method of preparing iron and aluminum flocculant by treating red mud by using coupling external field

A flocculant and red mud technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as reduced resource utilization efficiency, achieve uniform refinement of reaction, improve performance, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

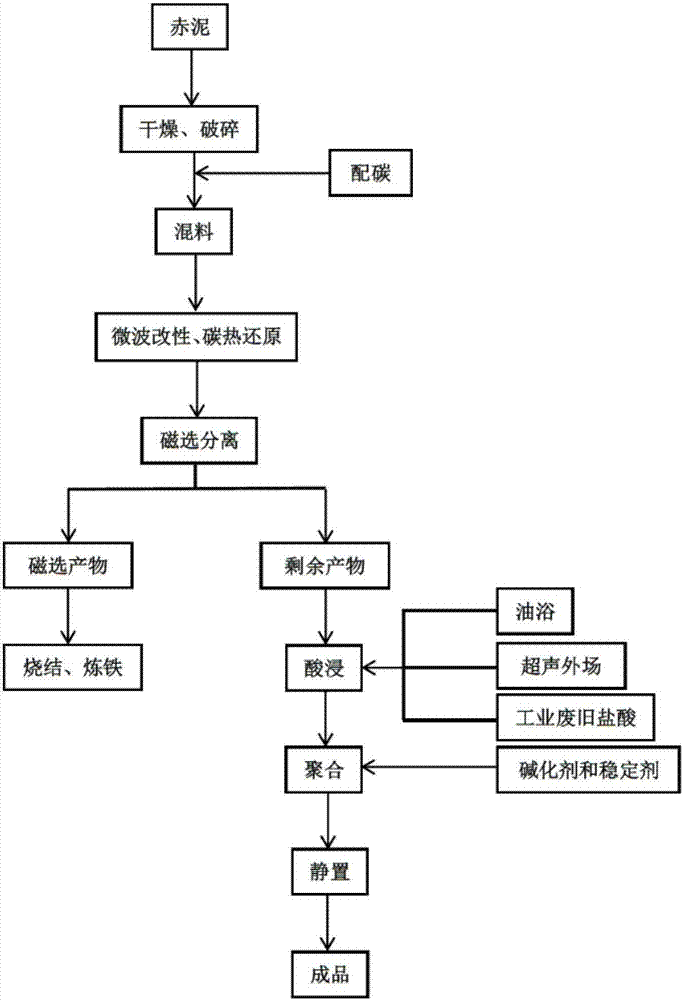

Method used

Image

Examples

Embodiment 1

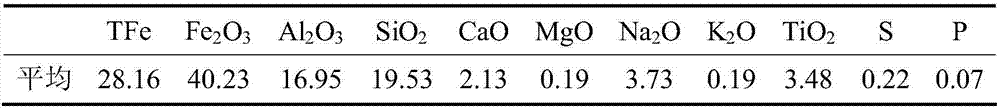

[0035] In this example, a high-iron red mud and a common coal were used to prepare the polyaluminum ferric chloride flocculant. The chemical composition of the high-iron red mud is shown in Table 1, and the chemical composition of the coal is shown in Table 2. (The composition TFe in Table 1 represents the total iron content, and the conversion is not included in the total amount, while substances such as P and S exist in the phase of the oxide in the form of oxides).

[0036] Table 1 Chemical composition of high-iron red mud (wt / %)

[0037]

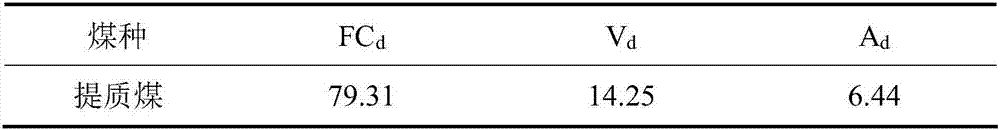

[0038] Chemical composition of table 2 coal (wt / %)

[0039]

[0040] The specific operation steps and methods of the preparation process are as follows:

[0041] (1) The red mud raw material is dried and crushed into a powder of less than 1 mm, and the coal selected as a carbon blending agent is also dried and ground to a size of less than 0.1 mm.

[0042] (2) The red mud and coal powder processed in the step (1) are proportioned...

Embodiment 2

[0055] In this example, a low-iron red mud and a common coal were used to prepare polyaluminum ferric chloride flocculant. The chemical composition of low-iron red mud is shown in Table 5, and the chemical composition of coal is shown in Table 6. (The composition TFe in Table 5 represents the total iron content, and the conversion is not included in the total amount, and substances such as P and S exist in the phase of the oxide in the form of oxides).

[0056] Table 5 Chemical composition of low-iron red mud (wt / %)

[0057]

[0058] The specific operation steps and methods of the preparation process are as follows:

[0059] (1) The red mud raw material is dried and crushed into a powder of less than 1 mm, and the coal selected as a carbon blending agent is also dried and ground to a size of less than 0.1 mm.

[0060] (2) The red mud and coal powder processed in the step (1) are mixed with the ratio of adding 86.5 grams of the coal powder per kilogram of red mud (the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com