Seasoning control method

A control method and warm-up technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of undisclosed equipment warm-up control methods, and achieve the effects of improving equipment utilization and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is a control method of a real-time dispatching system in the semiconductor manufacturing industry, more specifically, a control method for equipment warm-up in the real-time dispatching system of the semiconductor manufacturing industry.

[0030] The method of the invention is realized on the basis of a real-time dispatching system for semiconductor manufacturing, an automation system, a manufacturing execution system, a machine monitoring system and a handling system.

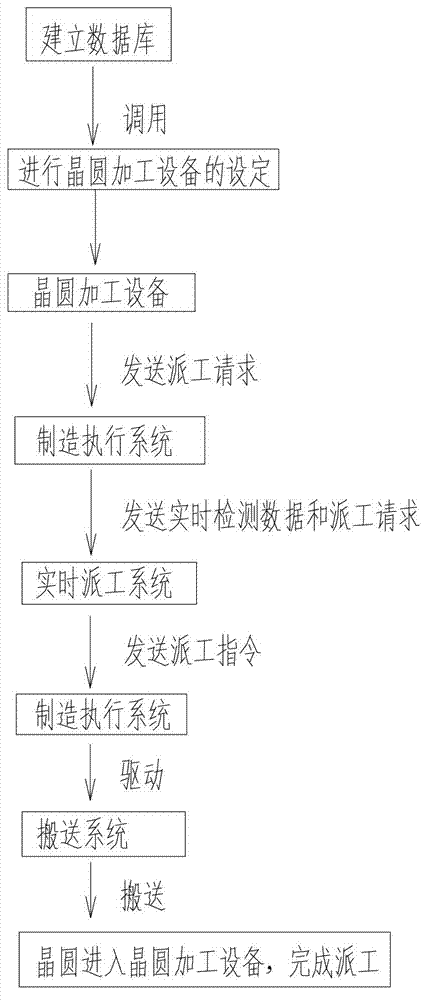

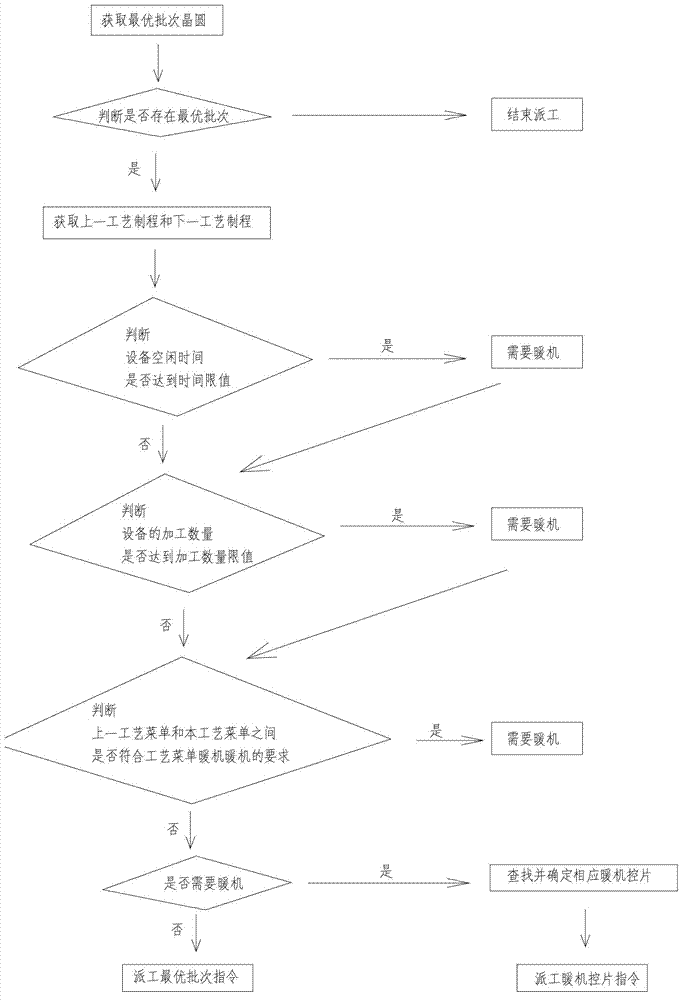

[0031] figure 1 It is a schematic diagram of the workflow of each system in the method embodiment of the present invention.

[0032] Such as figure 1 as shown,

[0033] A database including warm-up type information, warm-up condition information and warm-up control information is established.

[0034] Among them, the warm-up types in the database include three types, namely:

[0035] (1) Wafer processing equipment idle time warm-up (Idle season);

[0036] (2) Process menu change warm-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com