Strip flattening machine

A technology of flat strips and transformers, applied in the field of brazing material forming equipment, can solve problems such as bearings or copper sleeves being stuck, affecting production efficiency, curling, etc., and achieve the effects of easy heat dissipation, improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

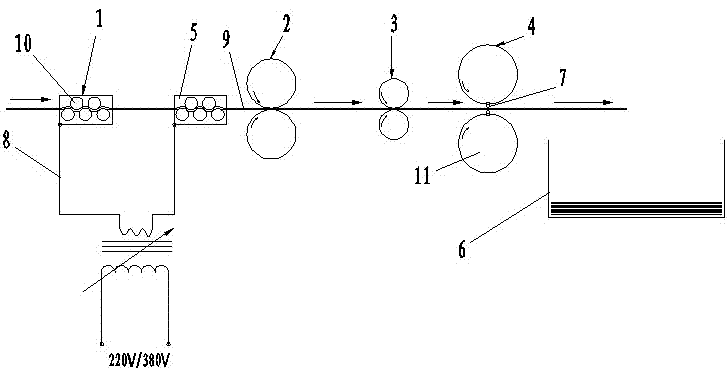

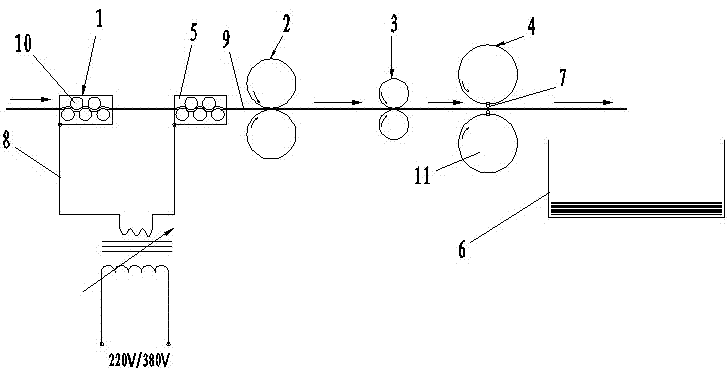

[0014] Embodiment 1: as figure 1 As shown, this embodiment consists of a front straightening roller electrode device 1, a flattening roller 2, a wire feed roller 3, a cutting device 4, a rear straightening roller electrode device 5, a storage cylinder 6, and a transformer 8.

[0015] The flattening roll 2, the wire feeding wheel 3, and the cutting device 4 are all arranged in pairs.

[0016] The cutting device 4 is made up of a cutting wheel 11 and a cutter head 7, the circumference of the cutting wheel 11 matches the length of the product to be obtained, and the two cutter heads 7 match each other and cut in half.

[0017] Five straightening rollers 10 are arranged in the front straightening roller electrode device 1, and the effect of this device is to have straightening function, can play again the electrode effect of electric energy transmission. Three of them are arranged below the alloy wire 9 and are parallel to each other, and the other two are arranged above the allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com