Method for preparing stable bisphenol sodium salt solution

A bisphenol sodium salt, stable technology, applied in the field of preparation of bisphenol sodium salt solution, can solve the problems of complex operation and high temperature, and achieve the effects of fast dissolution speed, extended life and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

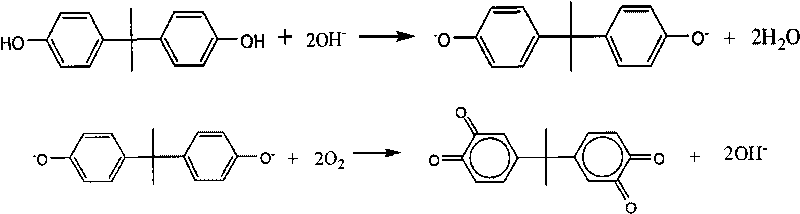

Image

Examples

Embodiment 1

[0035] Add 1.2g NaOH, 0.017gNa 2 S 2 o 4 and 0.01g Na 2 SO 3 , stirring and dissolving under the protection of nitrogen, then adding 2.7g of bisphenol A under continuous stirring, and dissolving at 30°C for 15 minutes to form a transparent bisphenol A sodium salt solution. Then, the ultraviolet absorbance of the bisphenol A sodium salt solution at 370 nm was measured by an ultraviolet photometer. Because if bisphenol A is oxidized to quinones, it will have a characteristic UV absorption at 370 nm. The larger the absorption value, the greater the degree of oxidation.

Embodiment 2

[0049] Add 1.2g NaOH, 0.017gNa 2 S 2 o 4 and 0.01g Na 2 SO 3 , stirring and dissolving under the protection of nitrogen, and then adding 2.7g of bisphenol A under continuous stirring, and dissolving at 80°C for 15 minutes to form a transparent bisphenol A sodium salt solution. Then, the ultraviolet absorbance of the bisphenol A sodium salt solution at 370 nm was measured by an ultraviolet photometer. Because if bisphenol A is oxidized to quinones, it will have characteristic ultraviolet absorption at 370nm, and the greater the absorption value, the greater the degree of oxidation.

Embodiment 3

[0059] Add 1.2gNaOH, 5mgNaOH to 12ml deionized water containing 1% (volume ratio) dichloromethane 2 S 2 o 4 and 0.4 mg Na 2 SO 3 , stirring and dissolving under the protection of nitrogen, then adding 2.3g of bisphenol A under continuous stirring, and dissolving at 30°C for 15 minutes to form a transparent bisphenol A sodium salt solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com