A kind of preparation method of graphene

A graphene and graphite intercalation technology, applied in the graphene field, can solve problems such as the reduction of effective substances, the intensification of ineffective decomposition, and the poor quality and performance of graphene products, so as to improve the expansion degree and uniformity, and promote effective decomposition reactions , Optimize the effect of complexation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

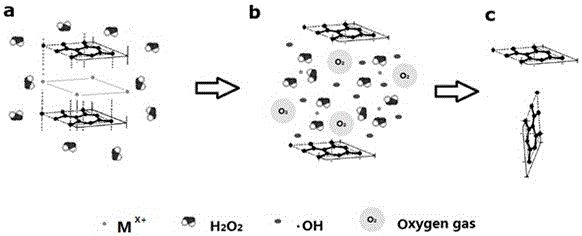

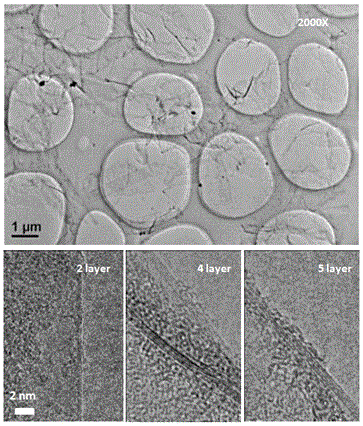

Method used

Image

Examples

Embodiment 1

[0066] A kind of preparation method of graphene, comprises the following steps:

[0067] a, the graphite intercalation compound powder is added in proportion to the composite expansion liquid, and then the expansion reaction is carried out under the condition of 0-100 ° C for 2-5 hours to obtain a highly expanded worm-like graphene aggregate suspension, wherein , the processing capacity of graphite intercalation compound per 1 ton of composite expansion liquid is 9-15Kg;

[0068] b. Filtrating the suspension of worm-like graphene aggregates to obtain worm-like graphene aggregates;

[0069] c. Use metal ion complexing agent and water to wash the worm-like graphene aggregates successively. After the metal ion complexing agent and water washing are completed, the worm-like graphene aggregates need to be filtered, and finally the pH value is obtained. 6-8 worm-like graphene aggregate wet material;

[0070] d. Add the wet material of worm-like graphene aggregates after washing in...

Embodiment 2

[0076] A kind of preparation method of graphene, comprises the following steps:

[0077] a. Add the graphite intercalation compound powder in proportion to the composite expansion liquid, and then carry out the expansion reaction at 20 °C for 2 hours to obtain a highly expanded worm-like graphene aggregate suspension, wherein, every 1 ton The graphite intercalation compound processing capacity of the composite expansion fluid is 9Kg;

[0078] b. Filtrating the suspension of worm-like graphene aggregates to obtain worm-like graphene aggregates;

[0079] c. Use metal ion complexing agent and water to wash the worm-like graphene aggregates successively. After the metal ion complexing agent and water washing are completed, the worm-like graphene aggregates need to be filtered, and finally the pH value is obtained. 6-8 worm-like graphene aggregate wet material;

[0080] d. Add the wet material of worm-like graphene aggregates after washing into water in proportion and perform ult...

Embodiment 3

[0088] A kind of preparation method of graphene, comprises the following steps:

[0089] a. Add the graphite intercalation compound powder in proportion to the composite expansion liquid, and then carry out the expansion reaction at 30°C for 3 hours to obtain a highly expanded worm-like graphene aggregate suspension, wherein, every 1 ton The graphite intercalation compound processing capacity of the composite expansion fluid is 11Kg;

[0090] b. Filtrating the suspension of worm-like graphene aggregates to obtain worm-like graphene aggregates;

[0091] c. Use metal ion complexing agent and water to wash the worm-like graphene aggregates successively. After the metal ion complexing agent and water washing are completed, the worm-like graphene aggregates need to be filtered, and finally the pH value is obtained. 6-8 worm-like graphene aggregate wet material;

[0092] d. Add the worm-like graphene aggregate wet material after washing into water in proportion and carry out ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com