Composite inflation liquid

A technology of expansion liquid and complexing agent, which is applied in the field of graphene, can solve the problems of inability to deal with metal ions, decrease in the amount of effective substances, and aggravation of ineffective decomposition, so as to ensure mildness and safety, ensure sufficiency, and easily obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

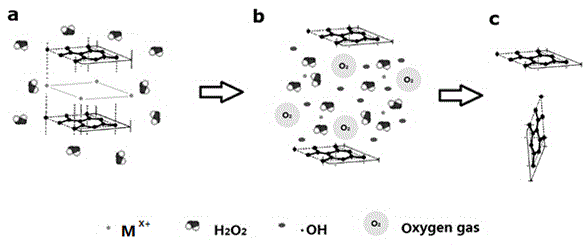

Method used

Image

Examples

Embodiment 1

[0021] A composite expansion liquid, which is uniformly mixed with the following components, each component and the mass percentage of each component are: 90% hydrogen peroxide solution, 1% metal ion complexing agent, 5% pH regulator, surface Tonicity regulator 0.5%, the rest is water. Wherein, the concentration of the hydrogen peroxide solution is 20%, and the metal ion complexing agent in the composite expansion liquid is one or both of potassium sodium tartrate and sodium pyrophosphate, and the composite expansion liquid is The pH adjusting agent is a compound of one or both of hydrochloric acid and sulfuric acid, and the surface tension adjusting agent in the compound swelling liquid is a compound of one or two of methanol and ethanol.

[0022] In this example, it has been proved by experiments that taking 4 parts of the same amount of graphite intercalation compound as an example, using the composite expansion liquid prepared by the above specific parameters for expansion...

Embodiment 2

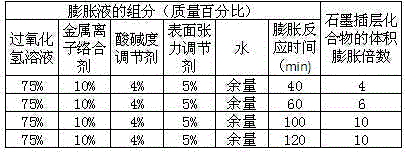

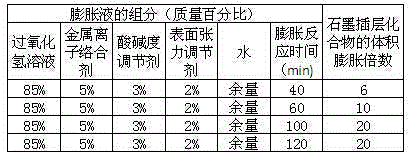

[0025] A composite expansion liquid, which is uniformly mixed with the following components, and the mass percentage of each component and each component is: hydrogen peroxide solution 85%, metal ion complexing agent 5%, pH regulator 3%, surface Tonicity regulator 2%, the rest is water. Wherein, the concentration of the hydrogen peroxide solution is 24%, and the metal ion complexing agent in the composite swelling liquid is a composite of one or more of sodium pyrophosphate, ethylenediaminetetraacetic acid sodium salt and oxalic acid, The pH regulator in the composite swelling liquid is a compound of one or more of phosphoric acid, oxalic acid, formic acid and acetic acid, and the surface tension regulator in the composite swelling liquid is one or both of propanol and butanol. compound of species.

[0026] In this example, it has been proved by experiments that taking 4 parts of the same amount of graphite intercalation compound as an example, using the composite expansion l...

Embodiment 3

[0029] A composite expansion liquid, which is uniformly mixed with the following components, and the mass percentage of each component and each component is: hydrogen peroxide solution 80%, metal ion complexing agent 8%, pH regulator 5%, surface Tonicity regulator 3.5%, the rest is water. Wherein, the concentration of the hydrogen peroxide solution is 27%, and the metal ion complexing agent in the composite swelling liquid is one or both of oxalate and sodium gluconate. The pH regulator is a compound of one or more of oxalic acid, ammonia water, sodium hydroxide and potassium hydroxide, and the surface tension regulator in the composite swelling liquid is one or both of butanol and ethyl acetate. compound of species.

[0030] In this example, it has been proved by experiments that taking 4 parts of the same amount of graphite intercalation compound as an example, using the composite expansion liquid prepared by the above specific parameters for expansion treatment for 40 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com