Method for preparing ZnO nano-rod array by pulse electromagnetic field

A nanorod array, pulsed electromagnetic field technology, applied in nanotechnology, zinc oxide/zinc hydroxide and other directions, can solve the problems of small aspect ratio and low verticality of ZnO nanorod array, and improve the photoelectric conversion efficiency and verticality. High, favorable effect of electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

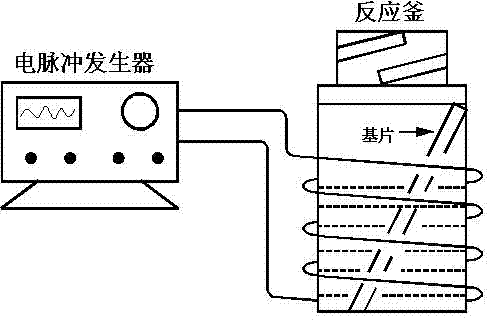

[0025] Such as figure 1 Shown, the method for preparing ZnO nanorod array is as follows:

[0026] Put the FTO conductive glass sheet (size: 20×20×3mm) in an ultrasonic cleaner at a temperature of 80°C for 5 minutes, take it out, rinse it with deionized water, and dry it in a vacuum oven for 5 hours; use zinc acetate, ethanolamine Prepare a mixed solution with ethylene glycol methyl ether, in which ethylene glycol methyl ether is used as a solvent, the volume ratio of zinc acetate:ethanolamine:ethylene glycol methyl ether=15:18:100, take 3ml of the prepared mixed solution and drop it on the conductive glass The sheet was coated evenly with a coating machine for coating, and the FTO conductive glass sheet coated with the mixed solution was placed in a tubular heating furnace, heated to 300 ° C, kept for 10 minutes, and cooled to room temperature; repeat the second step 4 times, in the A layer of dense and uniform ZnO film is obtained on the FTO conductive glass sheet.

[0027]...

Embodiment 2

[0030] Put the FTO conductive glass sheet (size: 20×20×3mm) in an ultrasonic cleaner at 75°C for 4 minutes, take it out, rinse it with deionized water, and dry it in a vacuum oven for 4 hours; use zinc acetate, ethanolamine Prepare a mixed solution with ethylene glycol methyl ether, in which ethylene glycol methyl ether is used as a solvent, the volume ratio of zinc acetate:ethanolamine:ethylene glycol methyl ether=8:8:100, take 1ml of the prepared mixed solution and drop it on the conductive glass The film was evenly coated on the sheet and coated with a coating machine, and the FTO conductive glass sheet coated with the mixed solution was placed in a tubular heating furnace, heated to 280 ° C, kept for 7 minutes, and cooled to room temperature; repeat the second step 3 times, in the A layer of dense and uniform ZnO film is obtained on the FTO conductive glass sheet.

[0031] Dissolve zinc chloride in deionized water to prepare a precursor solution with a concentration of 0.1...

Embodiment 3

[0033]Put the FTO conductive glass sheet (size: 20×20×3mm) in an ultrasonic cleaner at a temperature of 85°C for 6 minutes, take it out, rinse it with deionized water, and dry it in a vacuum oven for 6 hours; use zinc acetate, ethanolamine Prepare a mixed solution with ethylene glycol methyl ether, in which ethylene glycol methyl ether is used as a solvent, the volume ratio of zinc acetate:ethanolamine:ethylene glycol methyl ether=20:30:100, take 4ml of the prepared mixed solution and drop it on the conductive glass The sheet was coated evenly with a coating machine for coating, and the FTO conductive glass sheet coated with the mixed solution was placed in a tubular heating furnace, heated to 340 ° C, kept for 15 minutes, and cooled to room temperature; repeat the second step 5 times, in the A layer of dense and uniform ZnO film is obtained on the FTO conductive glass sheet.

[0034] Dissolve zinc chloride in deionized water to prepare a precursor solution with a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com