Installation structure of train roof jumper cable of urban rail

A technology for jumping cables and installation structures, which is applied in the installation of cables, cable arrangement between relatively moving parts, electrical components, etc., can solve the problems of large frame space, low work efficiency, long cable paths, etc. Simple environment, small footprint, and short cable paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

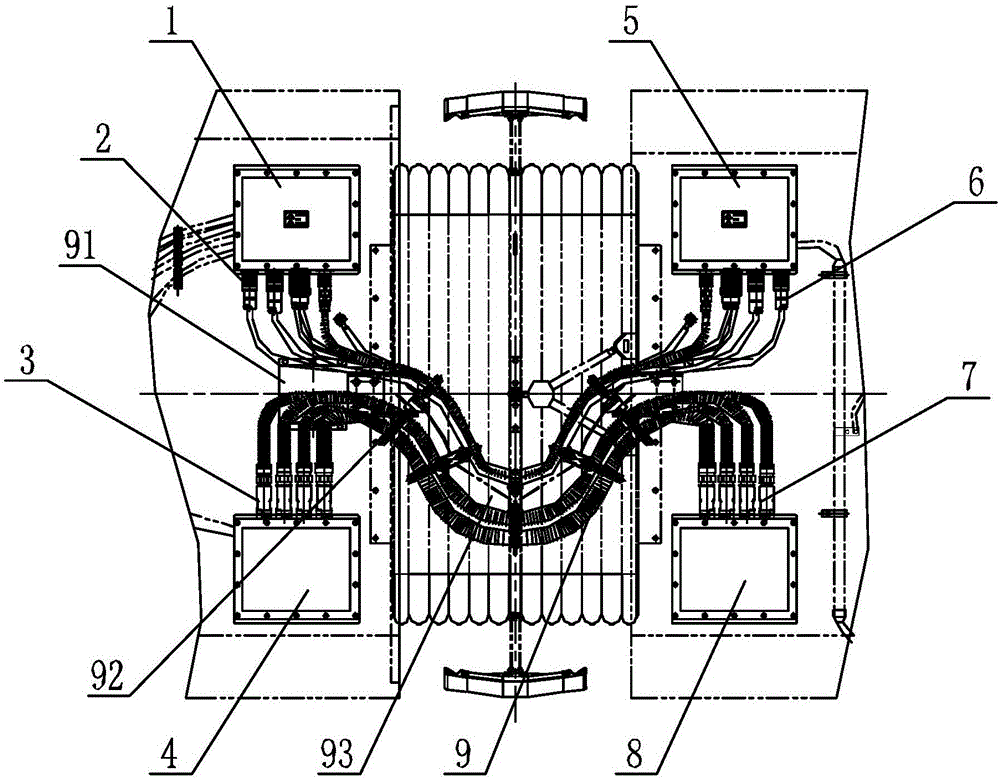

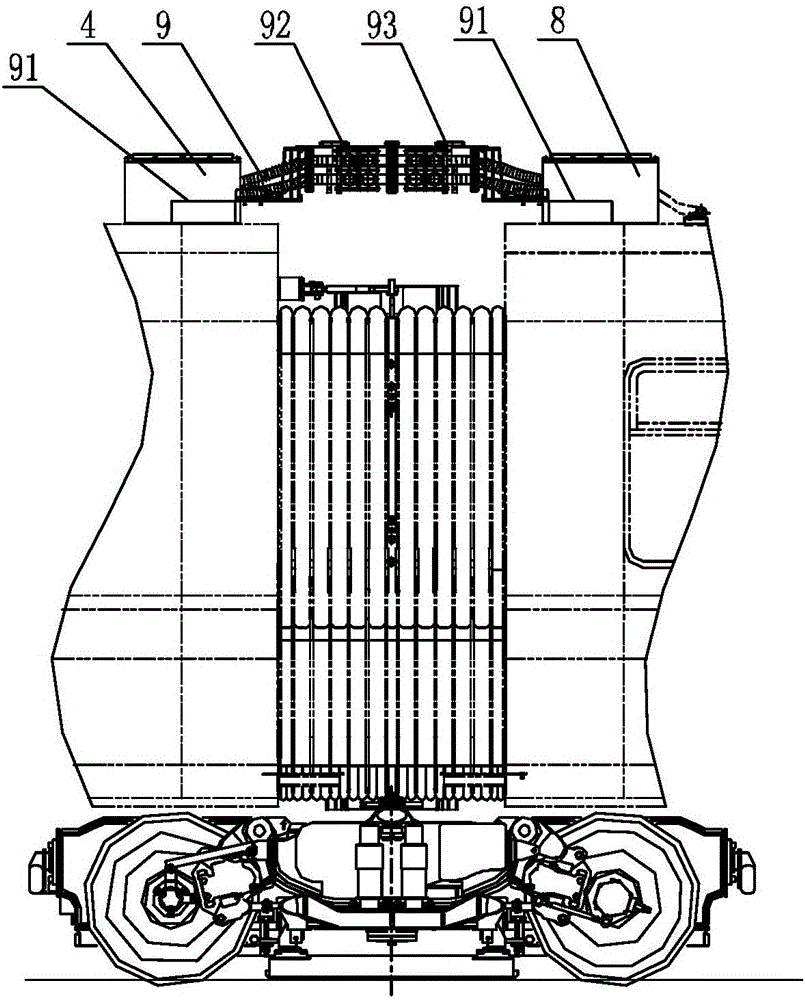

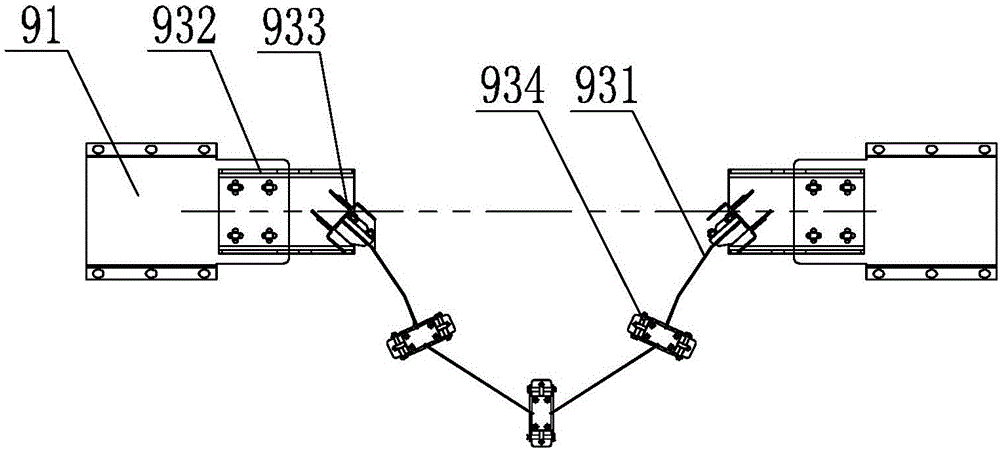

[0081]Embodiment: According to the marshalling mode and structural characteristics of the train, two sets of roof jumper cable systems are used. Due to the reversing of the vehicle circuit, in order to ensure that the length of the high and low voltage cables remains uniform, the jumper cable 9 and the dynamic flexible wiring frame 93 are installed in reverse, the high-voltage connector box 1, the high-voltage connector box 2 5, and the low-voltage connector box 14. Low-voltage connector box 2 8 cross layout, the whole train is composed of two different sets of roof jumper cable systems, the first set of roof jumper cable system consists of high-voltage connector box 1, high-voltage connector box 2 5 , low-voltage connector box one 4, low-voltage connector box two 8, 9 sets of jumper cables 9, a dynamic flexible wiring rack 93, 10 sets of clamping plates 92, 2 protective support mounting seats 91, high and low voltage connectors 1 2. High and low voltage connector two 3, high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com