High-voltage power line tension insulator string forward spin live-wire altering method

A technology for strain-resistant insulator strings and high-voltage transmission lines, which is applied in the direction of overhead lines/cable equipment, suspension/strain insulators, etc. It can solve the problems of damaged insulator strings, high efficiency, and long maintenance cycle, etc., and achieves easy operation and large operating space , Improve the effect of insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

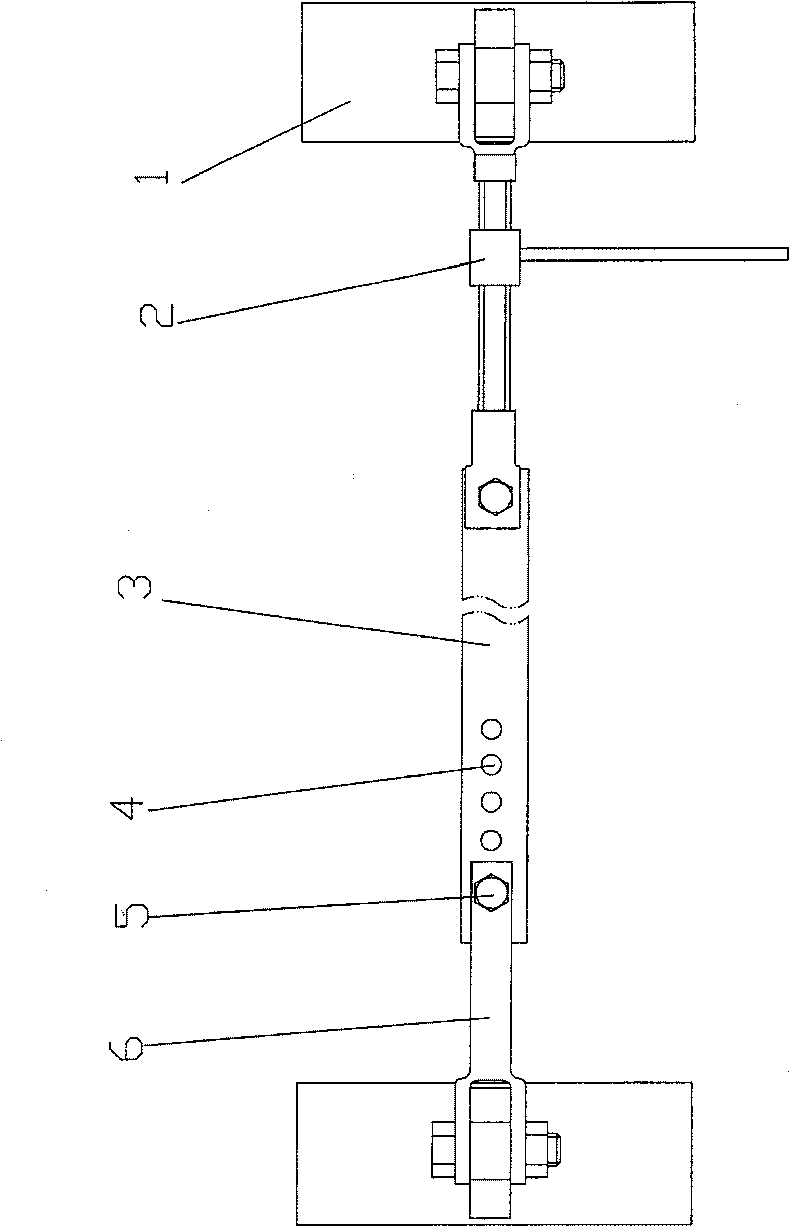

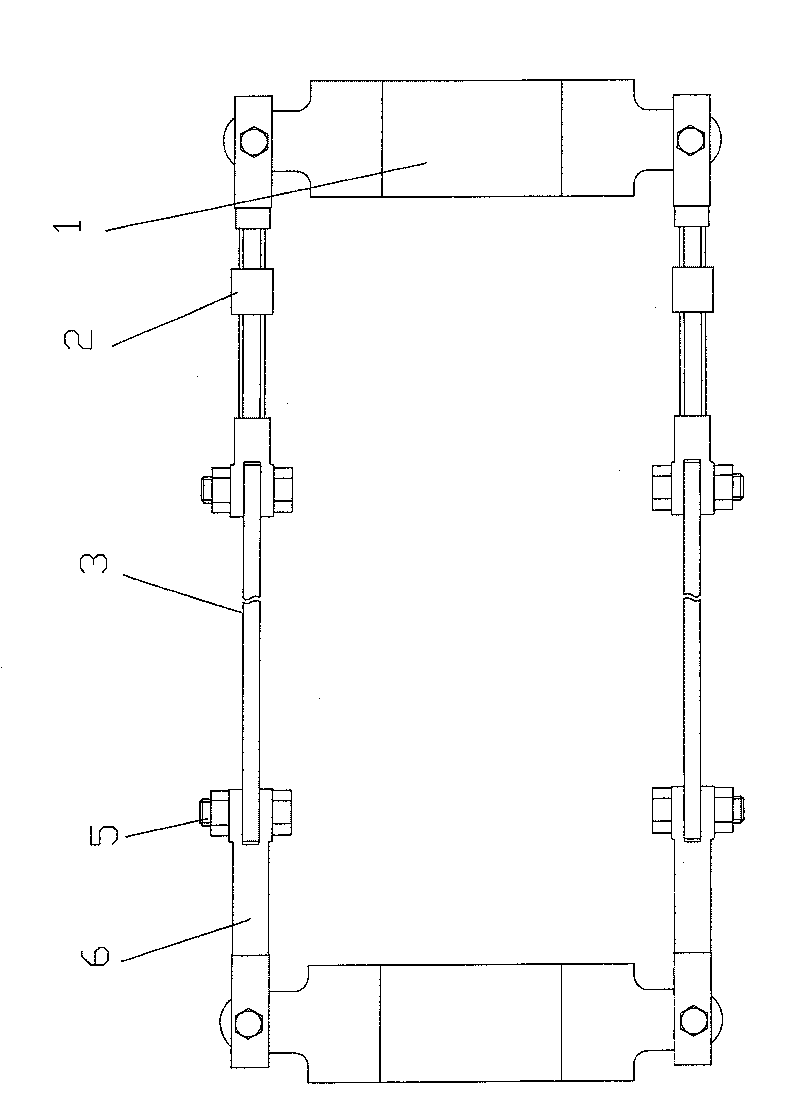

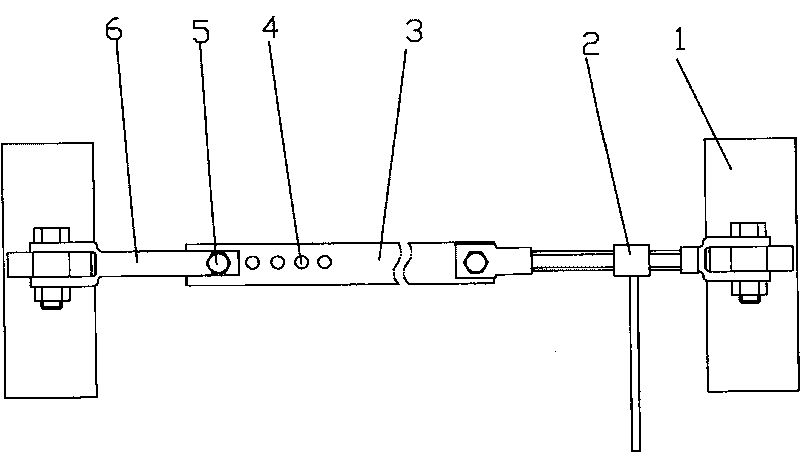

[0028] This embodiment is the replacement of the upper two insulator strings in the quadruple insulator string:

[0029] The method for replacing the tension insulator string of the high-voltage transmission line with live rotation on the present invention comprises the following steps:

[0030] ①Use the spark gap detector to test the zero-value insulators of the four strings of insulators to ensure that there are more than 23 good insulators, and it is determined that the insulator strings need to be replaced; On the side of the tension clamp, remove the pressure equalizing ring on the side of the insulator to be replaced, and fix the wing clamp through the two screw holes vacated by the front clamp at the end of the wing;

[0031] Another operator installs the rear clip of the wing-shaped end on the traction plate in front of the adjustment plate;

[0032] ②The front card of the wing-shaped end and the rear card of the wing-shaped end are connected by two sets of insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com