Venturi pipe and perforated plate combined-type hydrodynamic cavitation reaction chamber

A Venturi tube and hydraulic cavitation technology, applied in the direction of oxidized water/sewage treatment, can solve the problems of difficult to meet wastewater discharge standards and high processing costs of physical and chemical devices, and achieve the effects of easy visual observation, simple structure, and less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

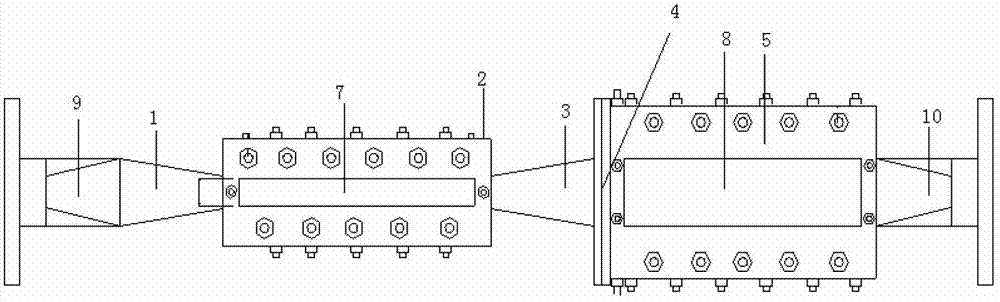

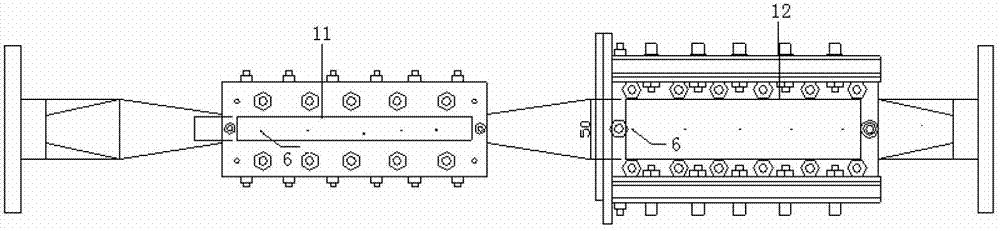

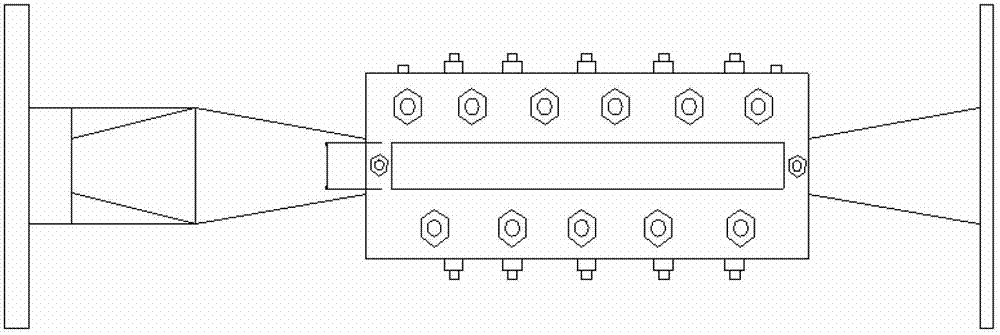

[0040] refer to Figure 1 to Figure 12 , Venturi tube and perforated plate combined hydraulic cavitation reaction chamber, comprising a Venturi tube and a bucket-type perforated plate device, the Venturi tube is connected to the bucket-type perforated plate device, and the Venturi tube is connected in sequence Constriction section 1, throat straight pipe section 2 and diffusion section 3; the liquid accelerates in the constriction section 1 of the Venturi tube so that the pressure drops, and in the throat straight pipe section 2 when the pressure of the liquid drops to the corresponding temperature of the liquid Cavitation occurs when the vapor pressure is saturated, and the cavitation continues to flow forward with the water flow, and the pressure rises again in the diffusion section 3 of the Venturi tube and the cavitation collapses; the inlet section and the outlet section of the Venturi tube and the throat directly The pipe section 2 is a square section, the two sides and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com