Impact-resistant and fireproof glass fiber reinforced phenolic aldehyde board and preparation method thereof

A technology of fiber reinforced material and glass fiber, which is applied in the field of glass fiber reinforced phenolic sheet and its preparation, can solve the problems of poor flame retardancy, combustion and smoke toxicity, etc., and achieve improved impact resistance, processing performance, and high production efficiency , fast forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention is a kind of impact-resistant, fireproof glass fiber reinforced phenolic sheet material preparation method for cargo hold liner, comprising the following steps:

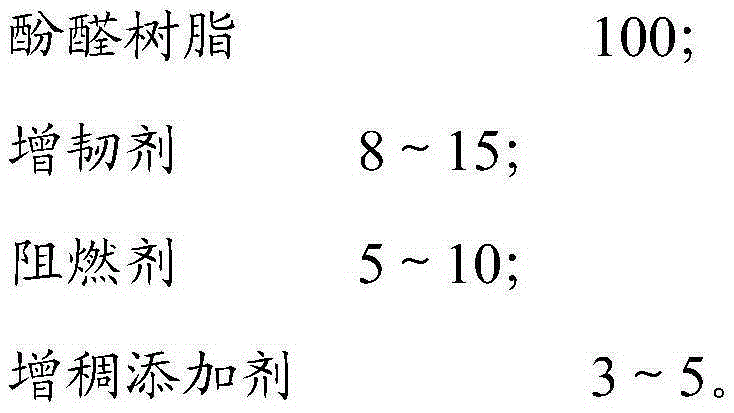

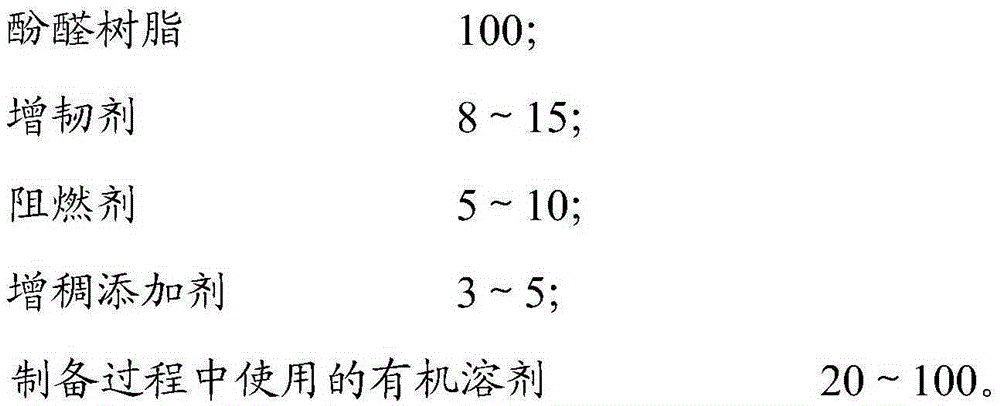

[0044] (1) In the state of low-speed stirring of the mixed solution of phenolic resin and organic solvent, add the above-mentioned corresponding toughening agent, flame retardant and additive to the resin in sequence, stir at high speed for 60-150 minutes, and then mix the stirred resin The liquid is ground by three rolls to obtain the modified phenolic resin matrix;

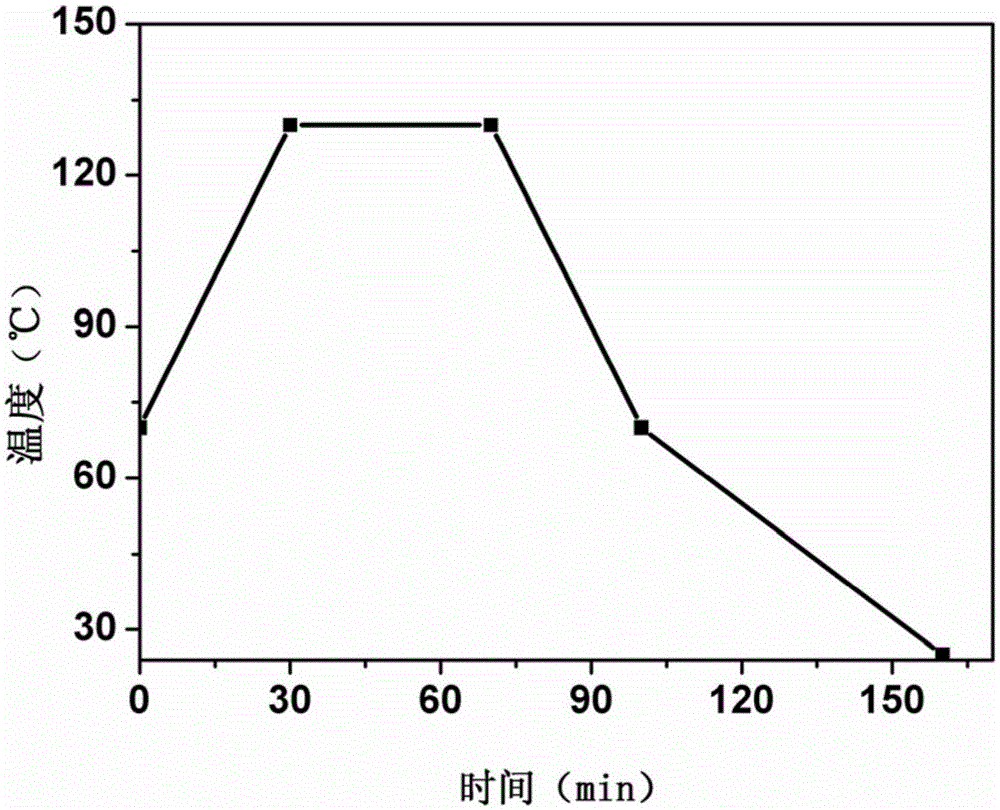

[0045](2) Use an organic solvent to dilute the specific gravity of the above-mentioned modified phenolic resin matrix to the range of 0.9 to 1.2, and then put it and the fiber reinforced material on a solution impregnation machine for continuous impregnation, post-drying and winding processes to prepare fiber reinforcement For phenolic prepregs, the volatile content of the prepregs should be less than 5%.

[0046] (3) Cut ...

Embodiment 1

[0059] It is required to prepare surface density specifications ≤976g / m 2 、≤1465g / m 2 、≤2051g / m 2 、≤2539g / m 2 and ≤3418g / m 2 The glass fiber reinforced phenolic sheet is used as a decorative liner and installed in different load-bearing areas inside the cargo hold. The preparation method steps are:

[0060] 1) Add 50kg of commercially available barium hydroxide catalyzed phenolic resin and 15kg of ethanol in a 100L reactor, and stir at a speed of 100 rpm to obtain a phenolic resin solution; then add 1.5kg polyvinyl butyral, 1.5kg Nano-nitrile rubber powder, 1.5kg nano-organosilicon, 1kg nylon particles, 1kg aluminum hydroxide, 1.5kg polyphosphate and 1.5kg nano-silica powder, then stirred at a speed of 500 rpm for 100 minutes, Finally, the stirred mixed solution is ground by three rollers to obtain the modified phenolic resin matrix;

[0061] 2) The modified phenolic resin matrix obtained in step 1) is diluted with an appropriate amount of ethanol, and the specific gravit...

Embodiment 2

[0064] It is required to prepare surface density specifications ≤ 2539g / m 2 The glass fiber reinforced phenolic sheet is used as a decorative liner and installed in a specific load-bearing area in the cargo hold. The preparation method steps are:

[0065] 1) Add 50kg of commercially available barium hydroxide catalyzed phenolic resin and 15kg of ethanol in a 100L reactor, stir at a speed of 100 rpm to obtain a phenolic resin solution; then add 2.5kg polyvinyl butyral, 1.5kg Nano-nitrile rubber powder, 1kg aluminum hydroxide, 1.5kg polyphosphate and 1.5kg nano-silica powder, then stirred at 500 rpm for 100 minutes, and finally passed the stirred mixture through three rollers Grinding to obtain a modified phenolic resin matrix;

[0066] 2) The modified phenolic resin matrix obtained in step 1) is diluted with an appropriate amount of ethanol, and the specific gravity of the solution obtained is 1.10; m 2 ) on the solution impregnation machine with the technological parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com