Wine box forming machine

A forming machine and wine box technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problem of uneven outer surface, difficulty in quality assurance, and easy misalignment of the initial lamination of facial paper and gray box, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

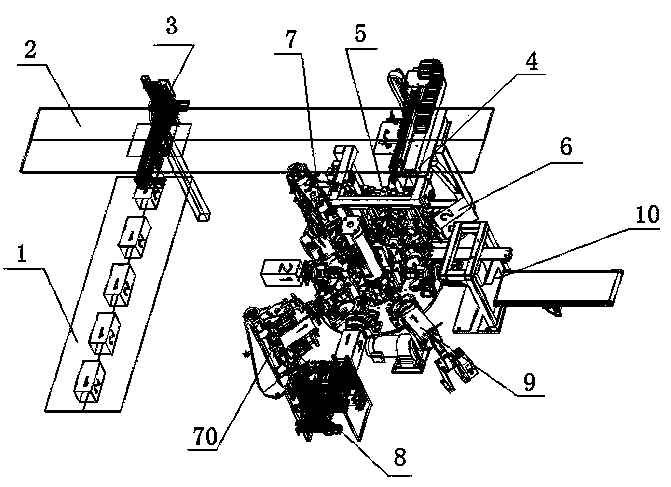

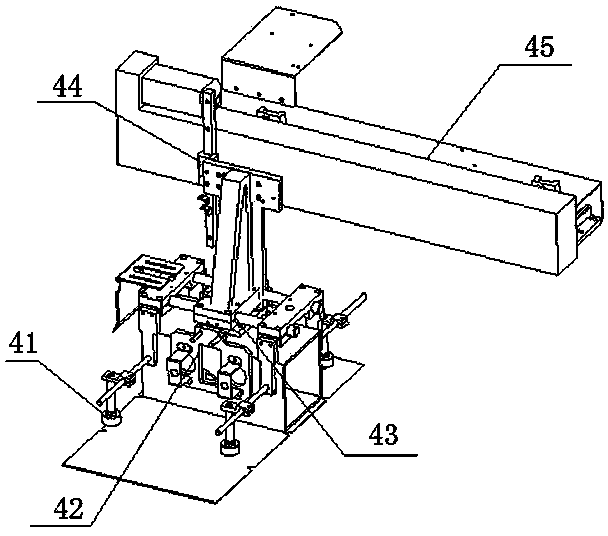

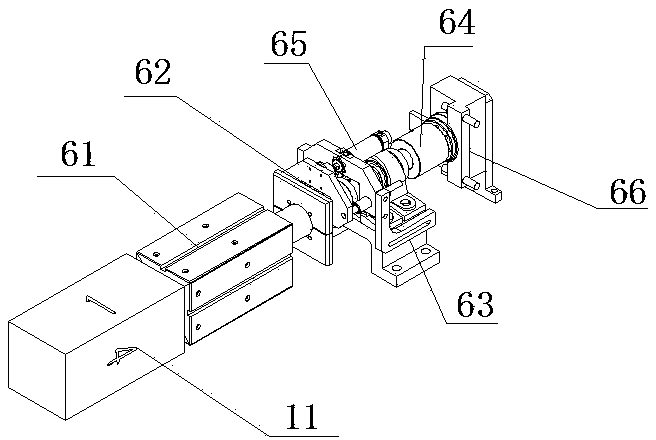

[0035] In this example, refer to Figure 1 to Figure 10 As shown, a wine box molding machine of the present invention includes a gray box conveyor belt 1 for conveying gray boxes, and a face paper arranged behind the gray box conveyor belt 1 and perpendicular to the conveying direction of the gray box conveyor belt 1 Conveyor belt 2, and be arranged on gray box conveyer belt 1 end back, the gray box conveying positioning mechanism 3 above facial tissue conveyer belt 2, and be arranged on the gray box feeding mechanism 4 of facial tissue conveyer belt 2 right-hand sides, and be arranged on gray box The gray box square peripheral tissue laminating mechanism 5 at the front end of the box feeding mechanism 4, and the carton carrying rotating mechanism 6 that is connected with the right end of the gray box square peripheral tissue laminating mechanism 5, and is arranged on the gray box square peripheral surface Paper pasting mechanism 5 left front, the first crimping mechanism 7 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com