Laminated glass corner processing method and special worktable device

A processing method and workbench technology, which are applied in glass cutting devices, glass manufacturing equipment, metal processing equipment, etc., can solve the problems of scratches on the glass surface and low processing efficiency, so as to reduce production costs, improve processing efficiency, and reduce consumables. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

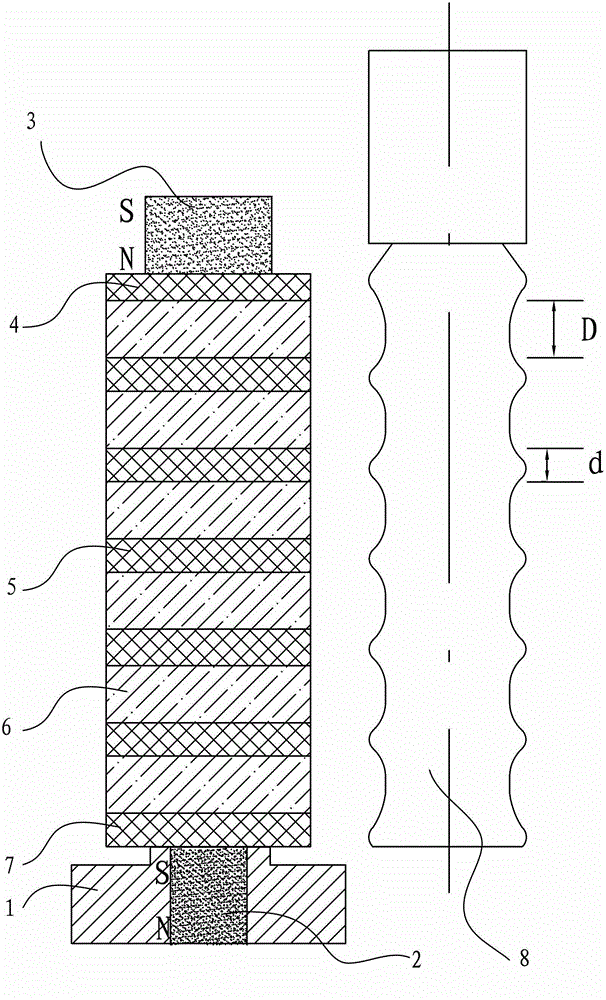

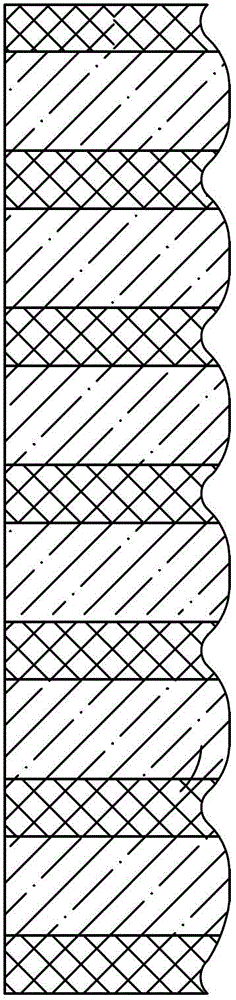

[0037] Prepare glass with the same shape and size according to the design parameters, as well as upper and lower protective layers and spacer layers, wherein the size of the upper and lower protective layers and spacer layers is basically equal to the size of the above-mentioned glass. The present embodiment chooses the glass sheet 6 that thickness is 0.8mm, gets 6, and thickness d is set between every adjacent glass sheet and is the spacer layer 5 of 0.5mm, and this spacer layer generally selects plastic sheet for use, such as PC material, PMMA material, Spacer layers keep the glass sheets at a distance of 0.5 mm. An upper protective layer 4 and a lower protective layer 7 with a thickness of 0.3-0.5mm are respectively arranged on the upper and lower surfaces of the whole stack of glass, and the upper and lower protective layers are also made of plastic sheets, which can protect the upper and lower glass surfaces from being scratched. The spacer layer of plastic material and t...

Embodiment 2

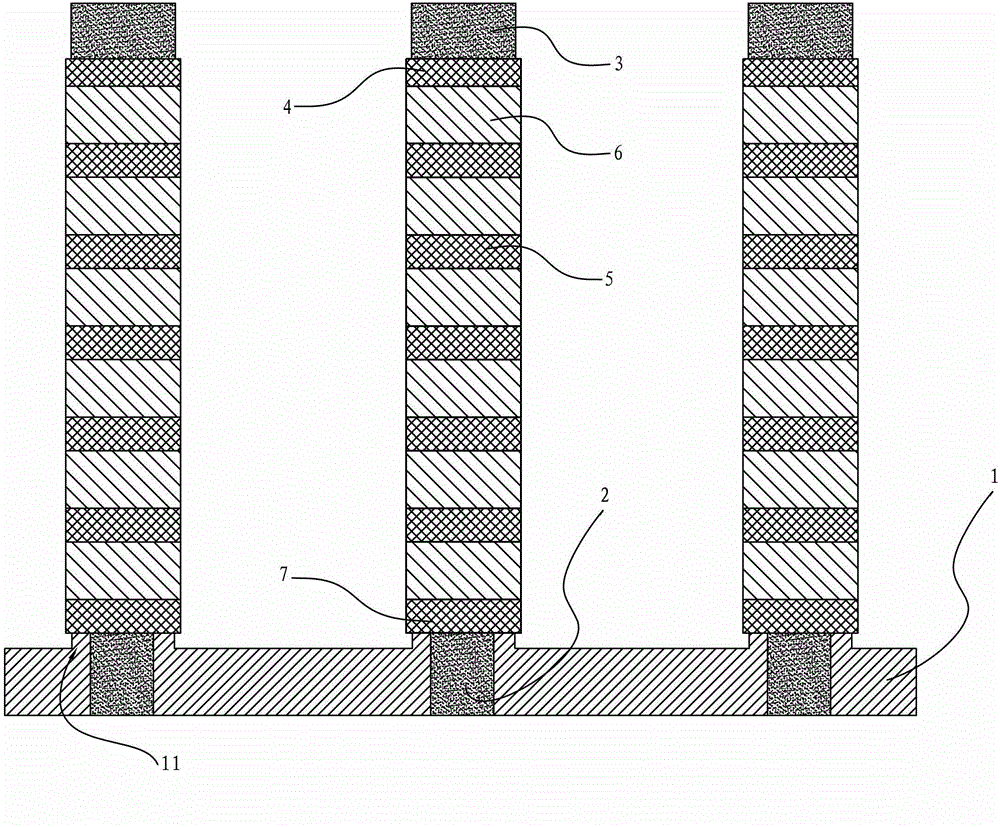

[0040] Such as image 3 As shown, the processing method and magnetic region structure are the same as those in Embodiment 1, the difference is that the workbench body 1 in the special workbench device has three bearing parts 11, and a whole stack of glass and powerful permanent magnets 23 are placed on each bearing part. . In this way, the special CNC tool performs chamfering and chamfering grinding on the 6 pieces of glass in each stack of glass sequentially according to the set CNC program instruction trajectory, which can timely replace the entire stack of glass to be processed, which is conducive to improving work efficiency.

Embodiment 3

[0042] Such as Figure 4 As shown, the processing method and the structure of the magnetic region are the same as in the first embodiment, the difference is that the workbench in the special workbench device is a rotary structure driven by a stepping motor, and the workbench body 1 protrudes four load bearing units at equal intervals in the radial direction. The bearing part 11 of the stacked glass, each bearing part is embedded with a powerful permanent magnet-2 to form a magnetic region, the magnetic field lines of the magnetic region are perpendicular to the plane of the bearing part, and the thickness of the magnetic region is greater than that of the workbench body to form a step, the step 19 The first function is to lengthen the axial length of the powerful permanent magnet 1 or the electromagnet to increase the magnetic strength, and the second is to prevent the bottom end of the special CNC tool 8 from touching the workbench during work, so that the CNC tool can be woun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com