Automatic die changing system for punching machine

A technology for automatic mold change and punching machines, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of hidden safety hazards and long time consumption, and achieve the goals of shortening time consumption, solving hidden dangers of safety, and improving mold changing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

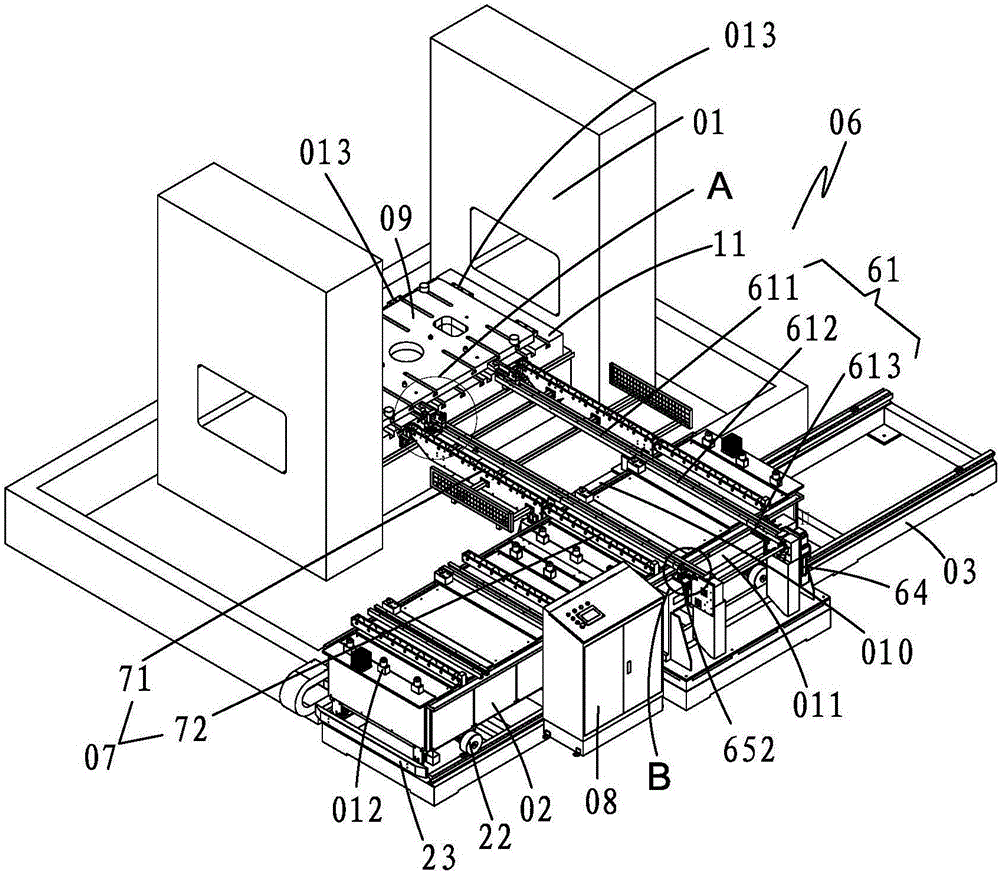

[0040] Please refer to Figure 1 to Figure 13 , the present invention is an automatic mold changing system for a punching machine, which includes a punching machine 01, a mold changing trolley 02, a trolley track 03 matching the mold changing trolley 02, and a mold changing trolley 02 in the The trolley positioning device 05 fixed on the trolley track 03, a mold changing fixture 06, two mold-moving arms 07 for transferring the mould, and a control cabinet 08, the table 11 of the punch press 01 is provided with a The exchange base plate 09 of the mold, the mold changing trolley 02 is slidably fitted on the trolley track 03, the trolley positioning device 05 is arranged on the side of the trolley track 03, and the two mold moving arms 07 are located on the side of the mold changing fixture 06 On both sides, the mold change trolley 02 moves along the trolley rail 03.

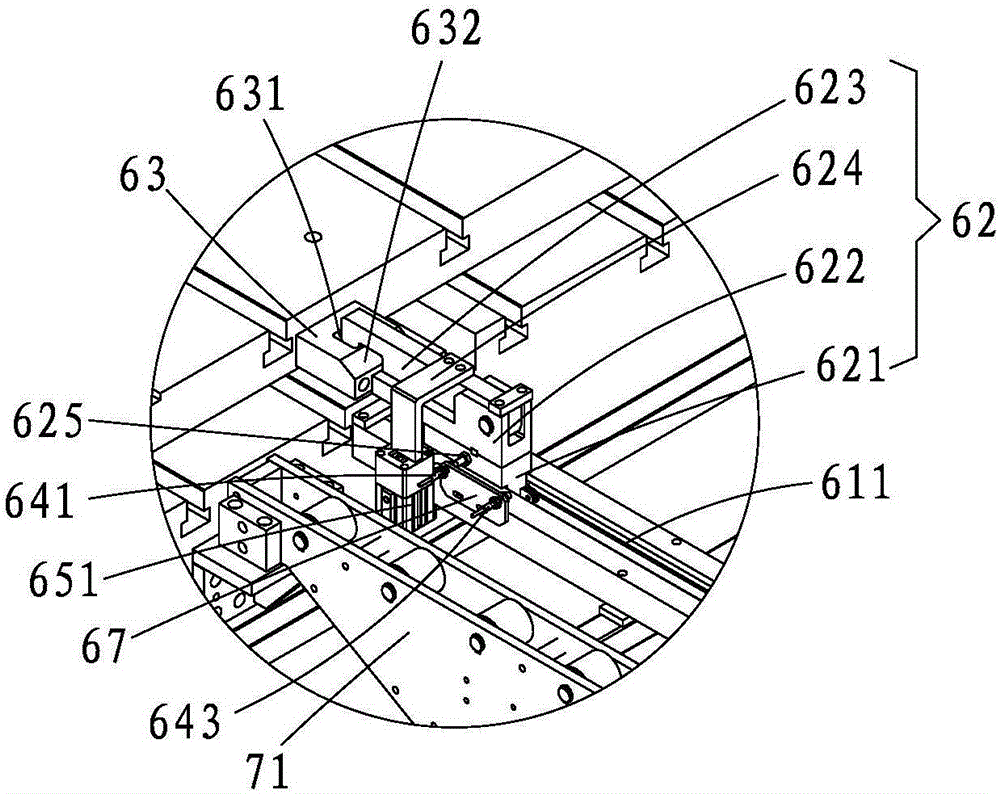

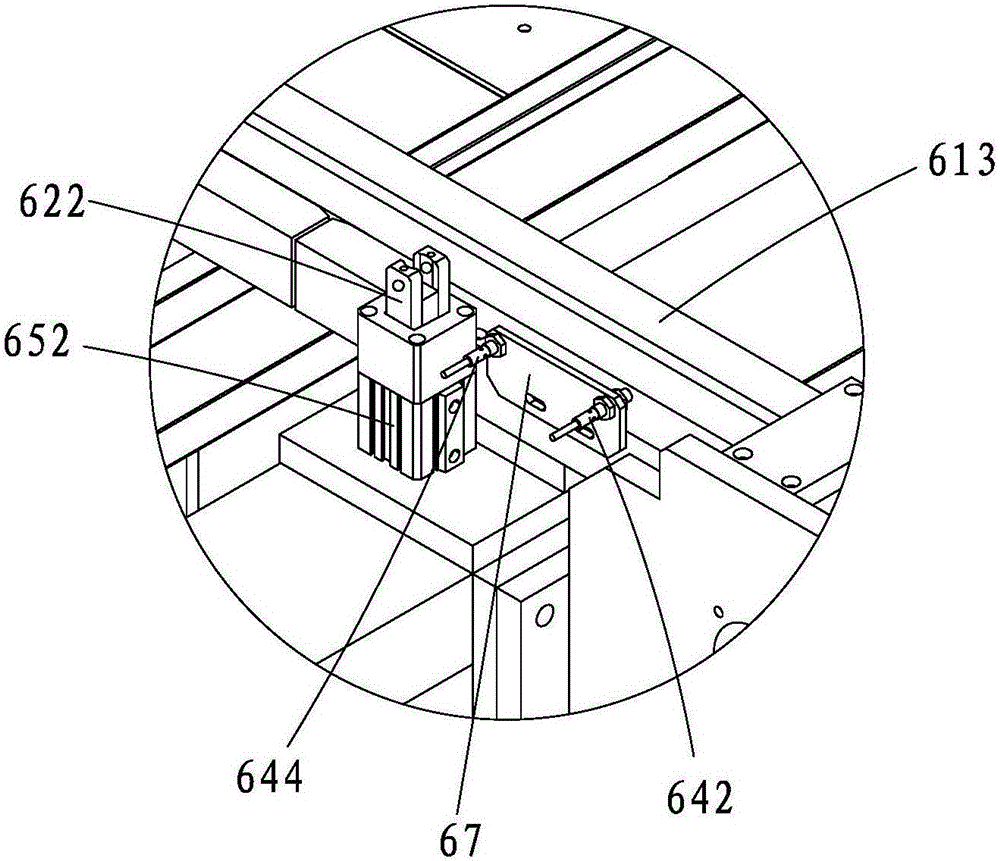

[0041] The mold changing fixture 06 includes two chain guide rails 61 arranged in parallel, two pushing devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com