Patents

Literature

82results about How to "Improve mold change efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

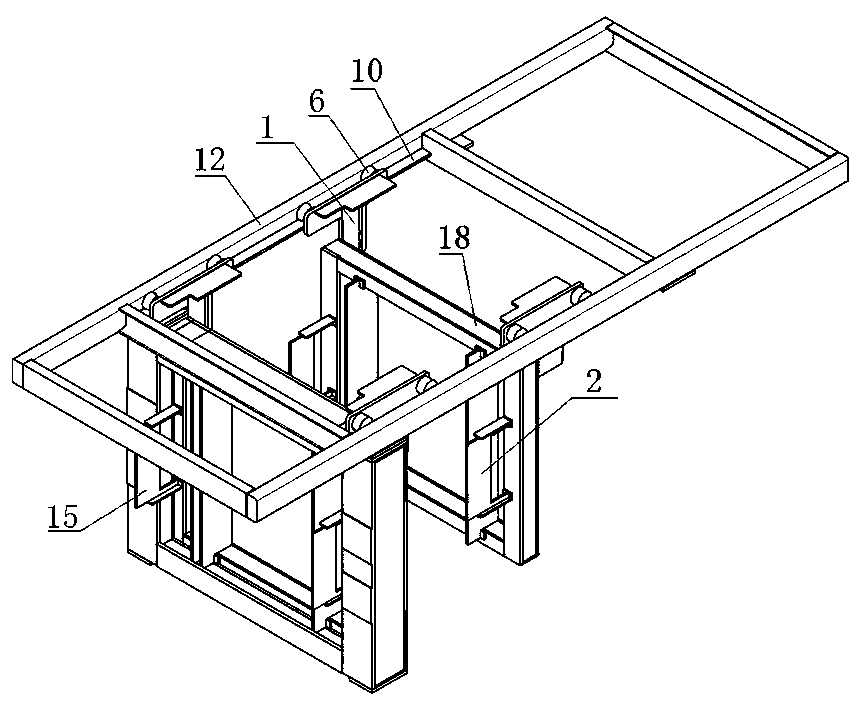

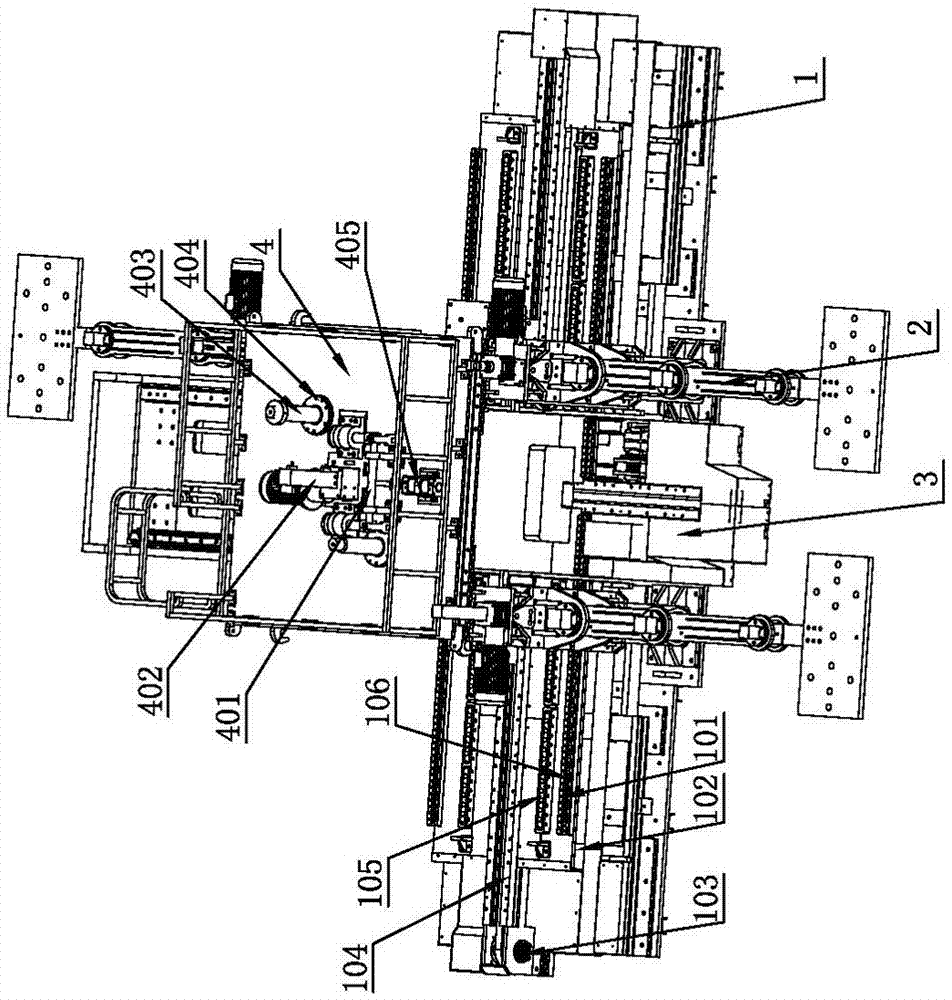

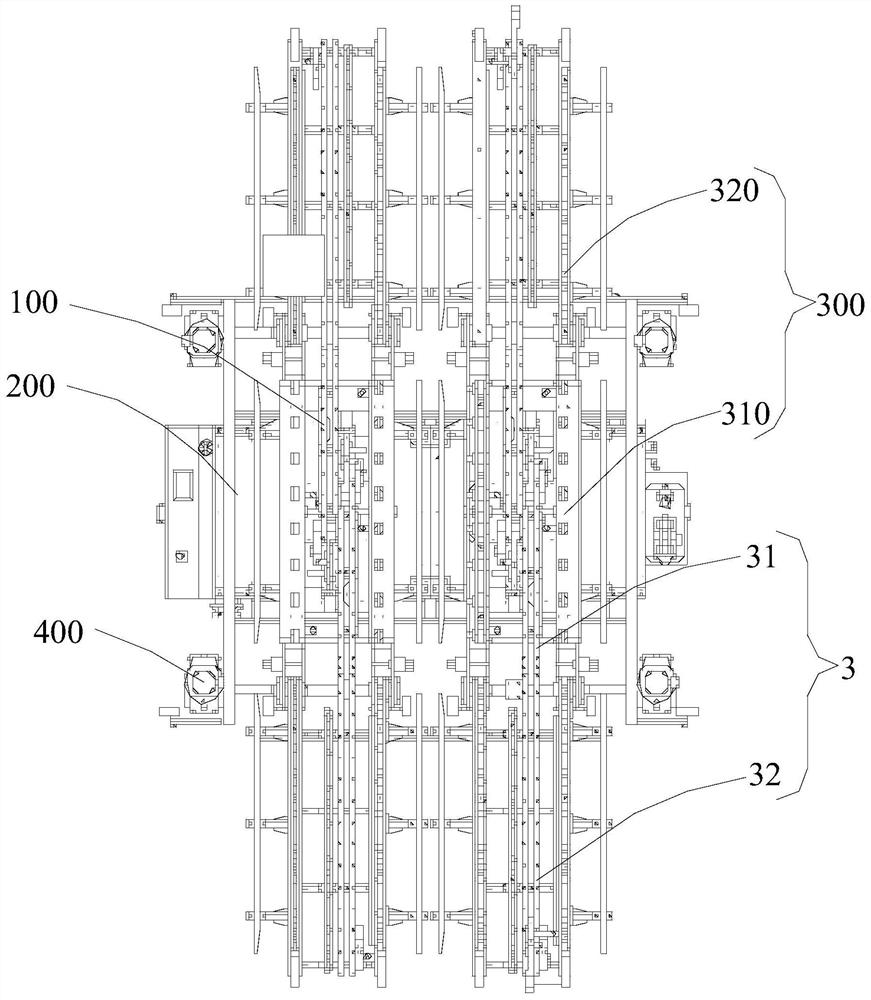

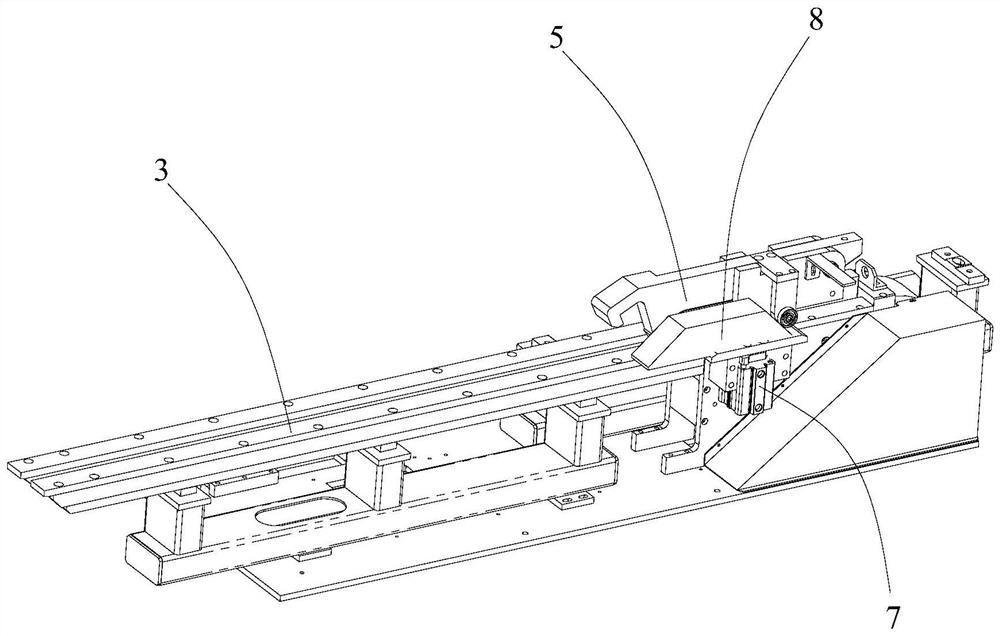

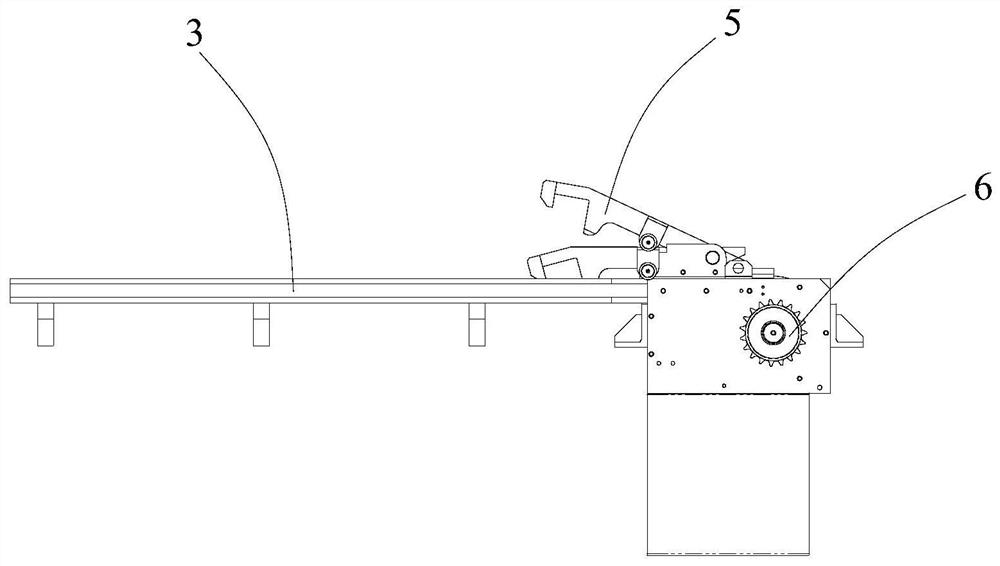

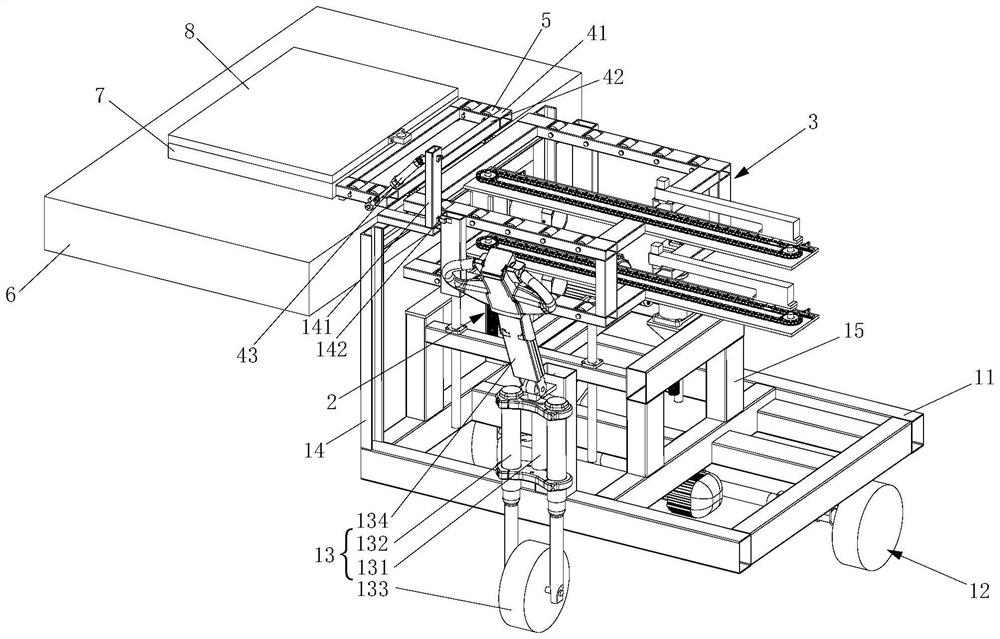

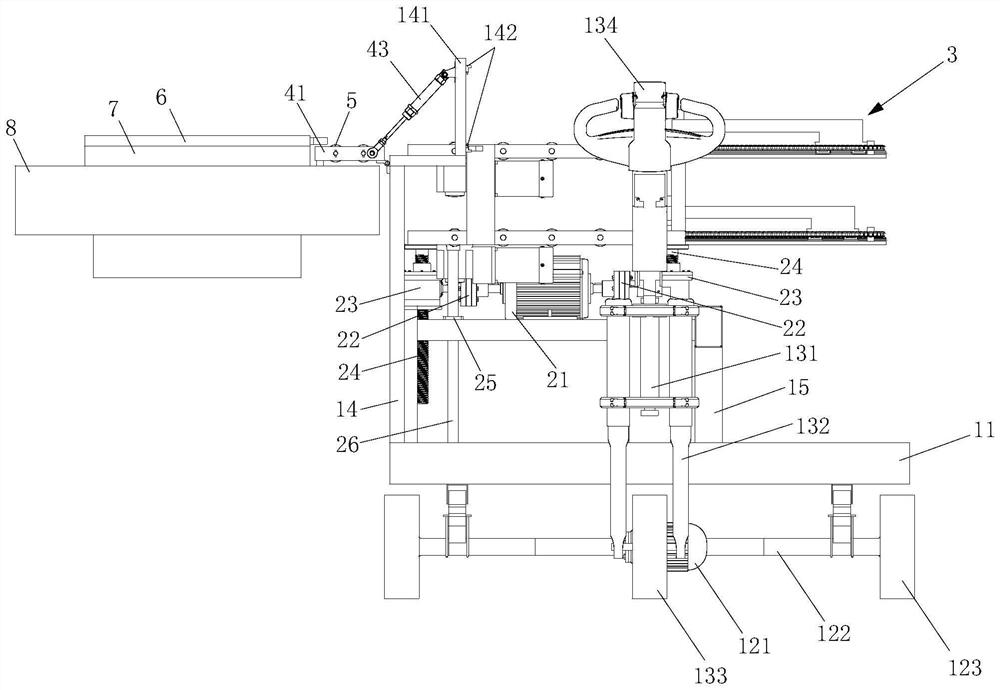

Stamping die change system and method

The invention provides a stamping die change system which is used for changing a die for a press and comprises a die library and a trolley moving rail, wherein the die library is used for storing the die and is connected with the press through the trolley moving rail. A die change trolley for conveying the die is arranged on the trolley moving rail, a die arrangement device for carrying the die is arranged between the die library and the trolley moving rail, a worktable is arranged on the press and in butt joint with the trolley moving rail to place the die, and a worktable conveying rail for conveying the worktable to the working position of the press is arranged on the press. The die is conveyed out of the die library, conveyed to the worktable of the press by the die change trolley, conveyed to the preset working position of the press by the worktable and stamped. The die is stored by the die library, conveyed by the die change trolley, automatically conveyed in placed by the worktable of the press and rapidly and accurately changed, and die change efficiency is improved. The invention further provides a stamping die change method.

Owner:GREE ELECTRIC APPLIANCES INC

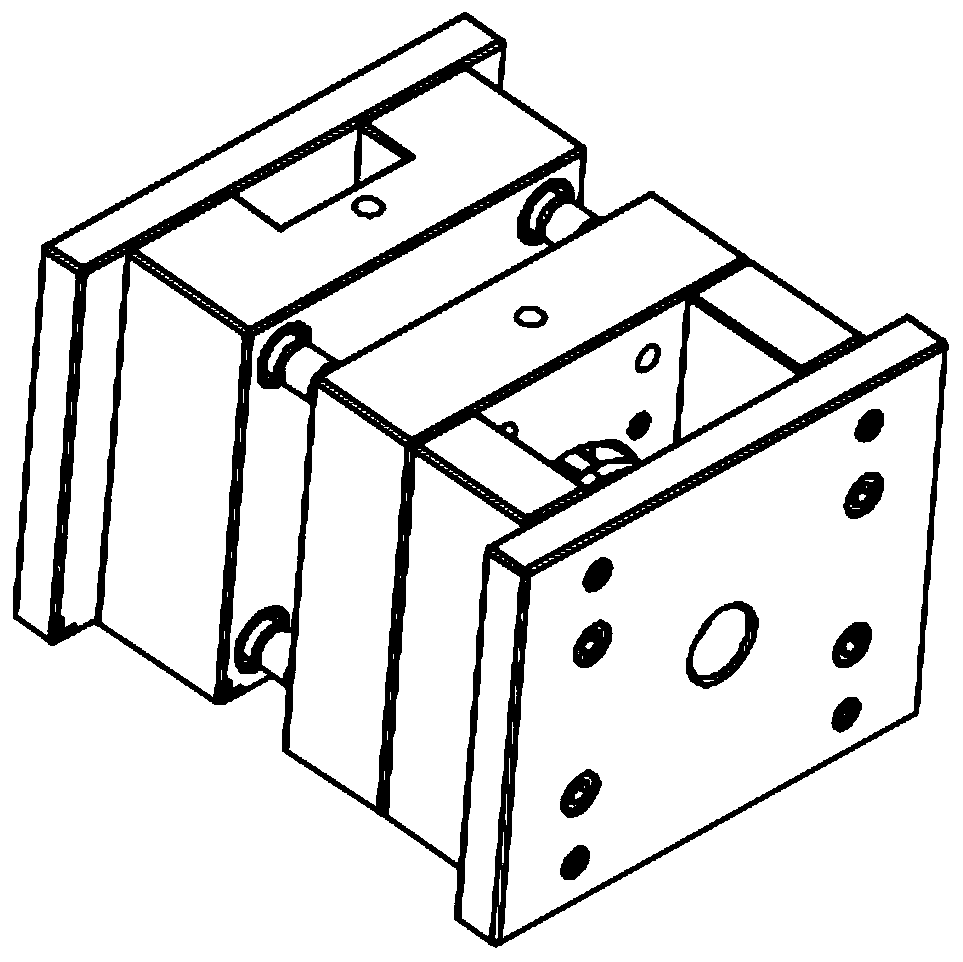

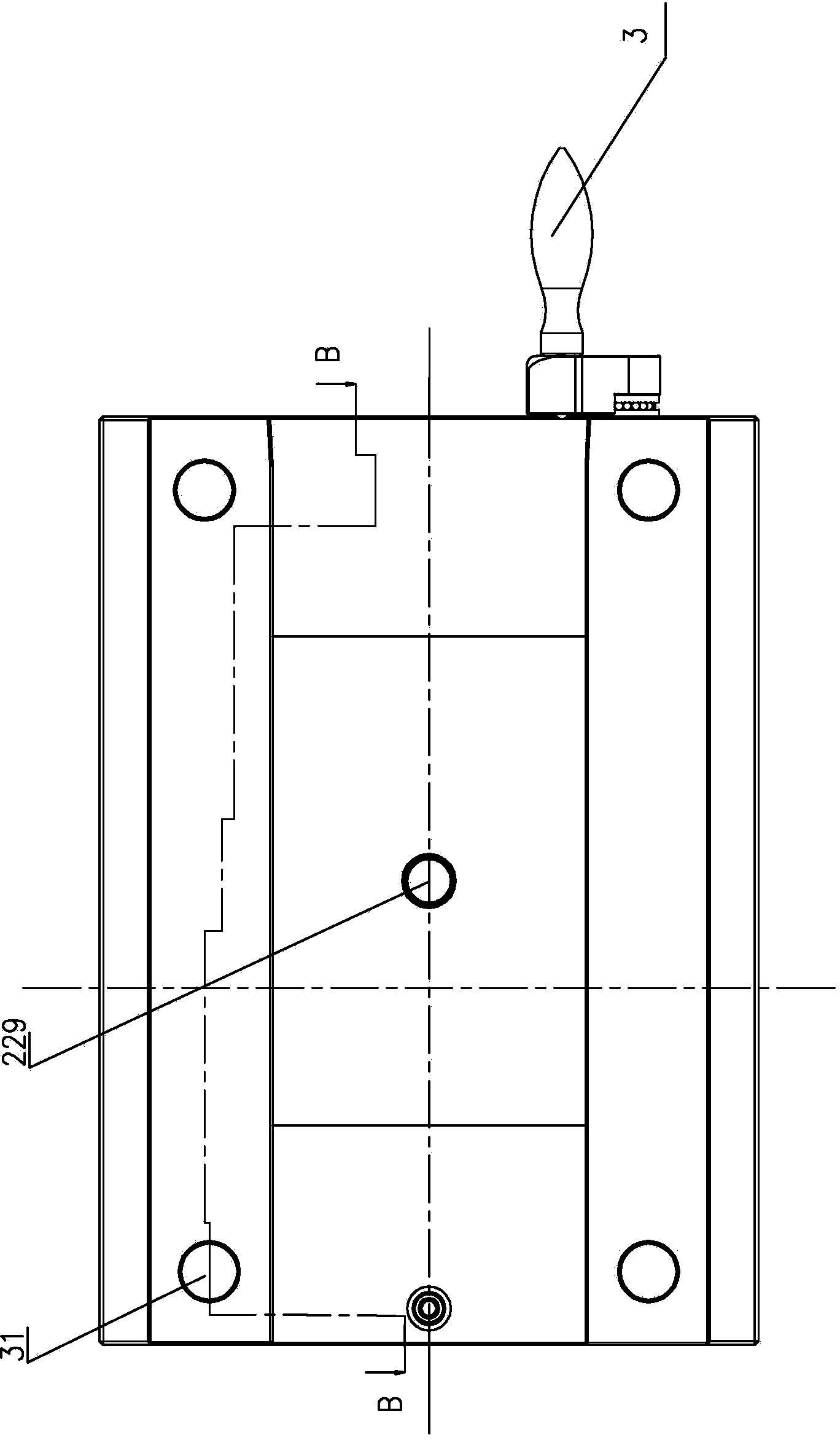

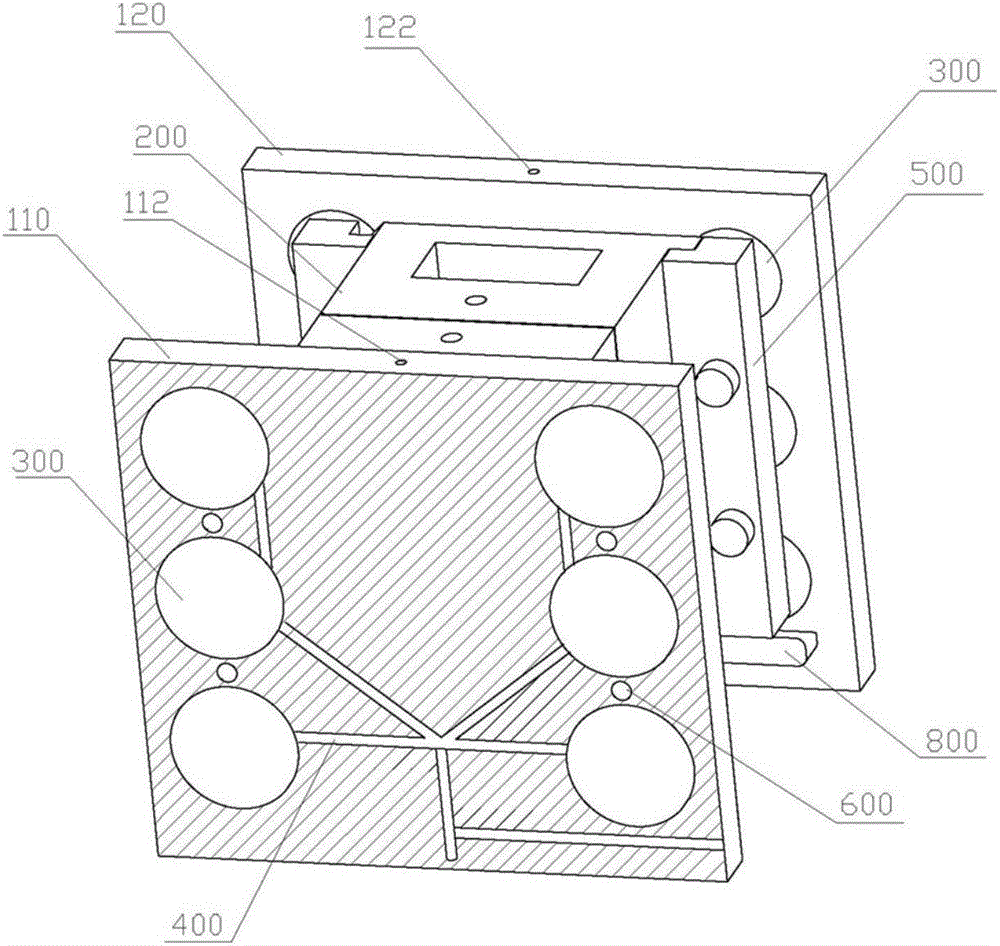

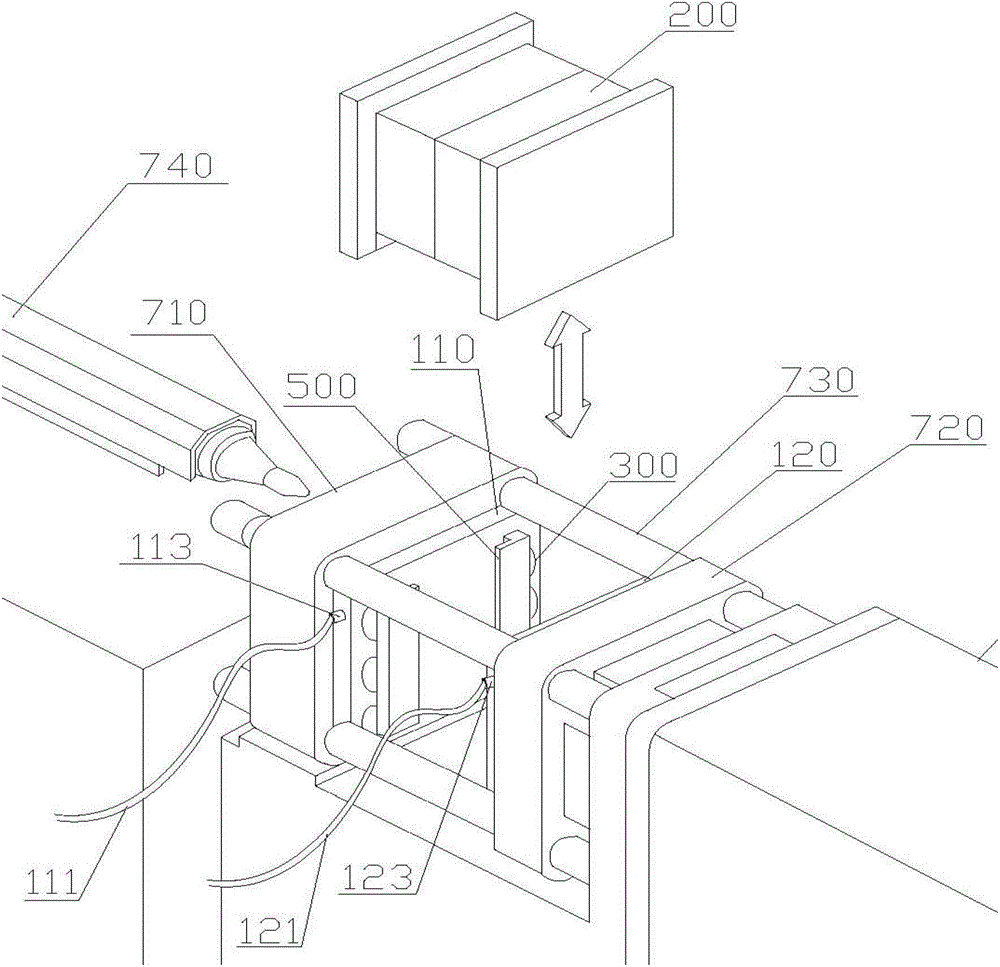

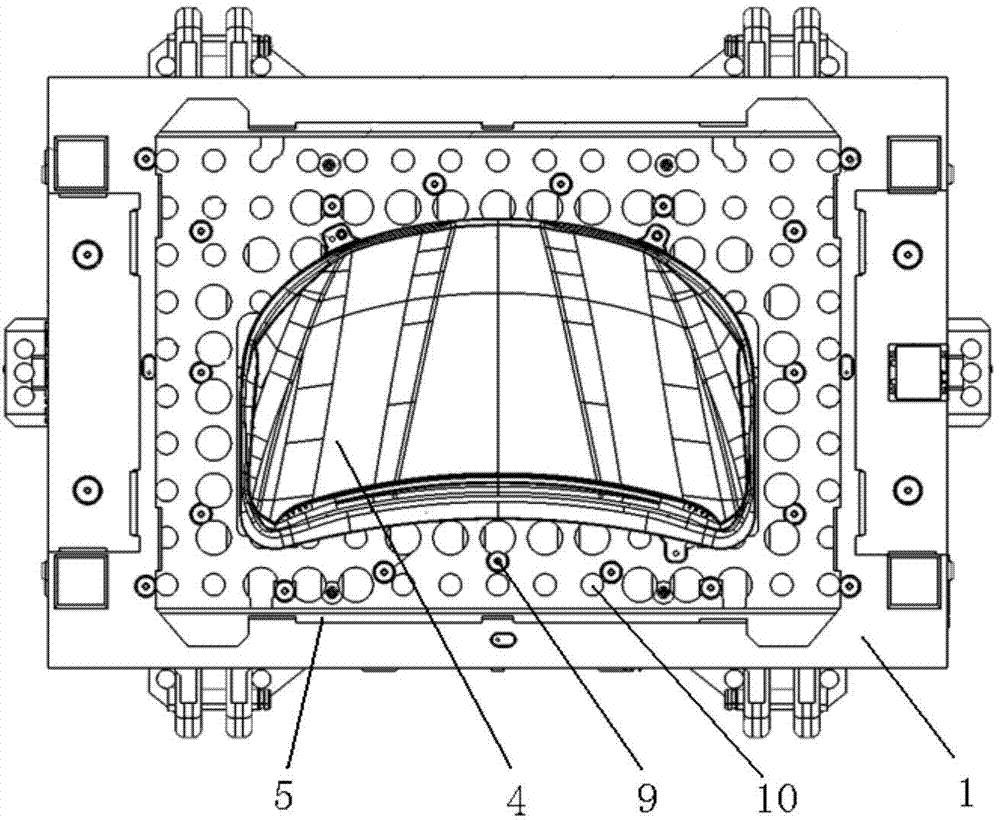

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

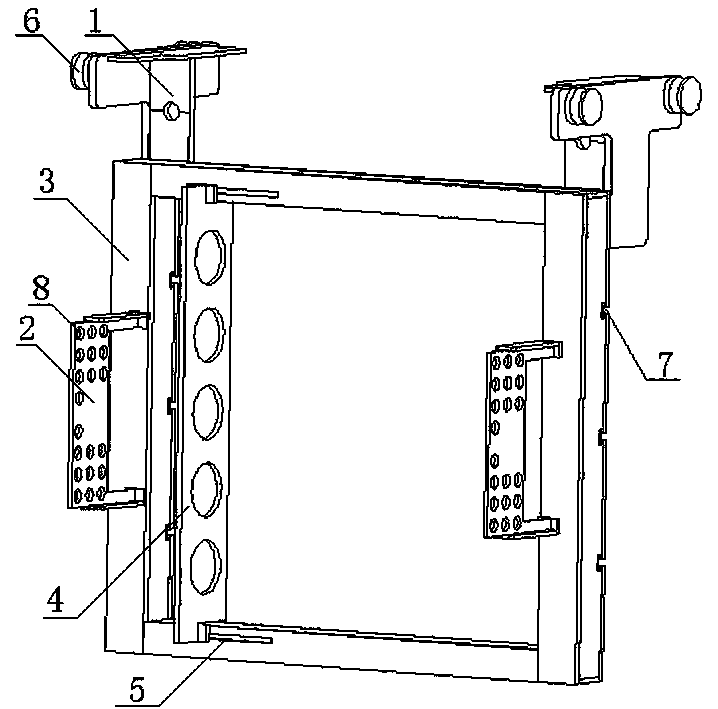

Matching structure of combined mold and punching machine for manufacturing flexible circuit board

InactiveCN102672758AGuarantee convenienceImprove mold change efficiencyMetal working apparatusManufacturing engineeringMechanical engineering

The invention discloses a matching structure of a combined mold and a punching machine for manufacturing a flexible circuit board, and belongs to the technical field of equipment for machining an electronic product. The combined mold comprises an upper mold and a lower mold; the punching machine comprises a pressing machine platform, a lower mold frame and an upper mold frame corresponding to the position above the pressing machine platform; the upper mold is arranged on the upper mold frame, and the lower mold is arranged on the lower mold frame, and corresponds to the upper mold; the surface of one side on the lower mold frame towards the upper mold frame is provided with a lower-mold drawer mechanism; the surface of one side on the upper mold frame towards the lower mold frame is provided with an upper-mold drawer mechanism which corresponds to the lower-mold drawer mechanism; the upper mold is matched with the upper-mold drawer mechanism; the lower mold is matched with the lower-mold drawer mechanism; a lower-mold handle is fixed on the lower mold; and an upper-mold handle is fixed on the upper mold. The matching structure disclosed by the invention has the advantages that since the lower mold frame is provided with the lower-mold drawer mechanism and the upper mold frame is provided with the upper-mold drawer mechanism, when the upper mold and the lower mold need to be replaced, the upper mold and the lower mold only need to be drawn out of the upper-mold drawer mechanism and the lower-mold drawer mechanism in a drawer effect, so that convenience for mold changing is guaranteed, the mold changing efficiency is increased, and the operating intensity of workers is reduced; and since the upper-mold handle and the lower-mold handle are provided, the convenience is brought for operators to grab.

Owner:苏州市飞莱克斯电路电子有限公司

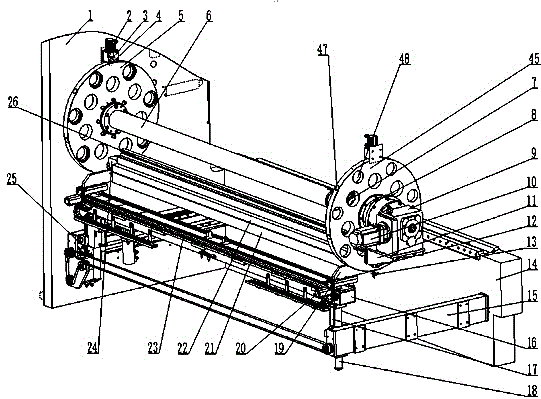

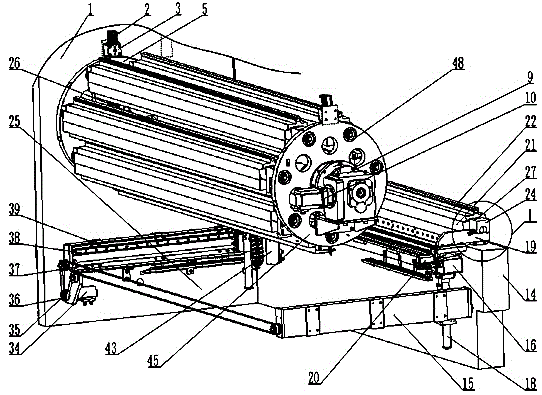

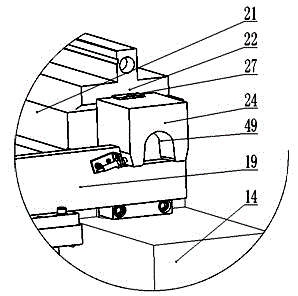

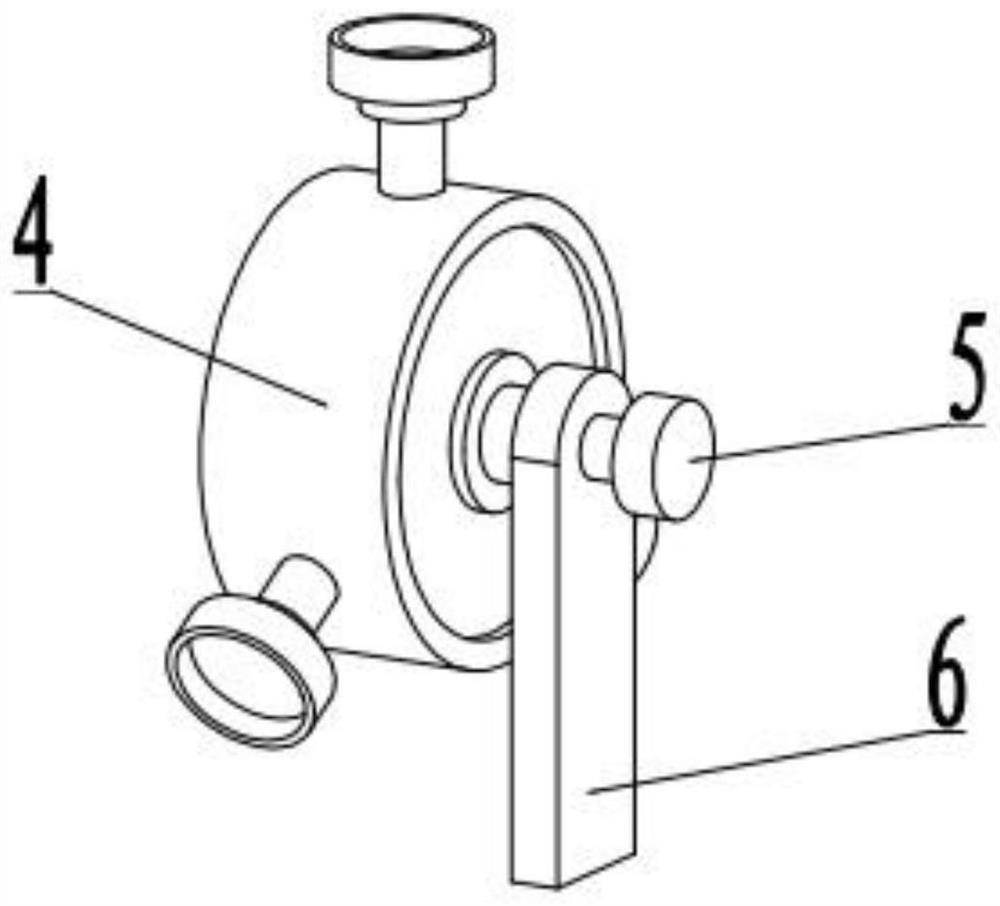

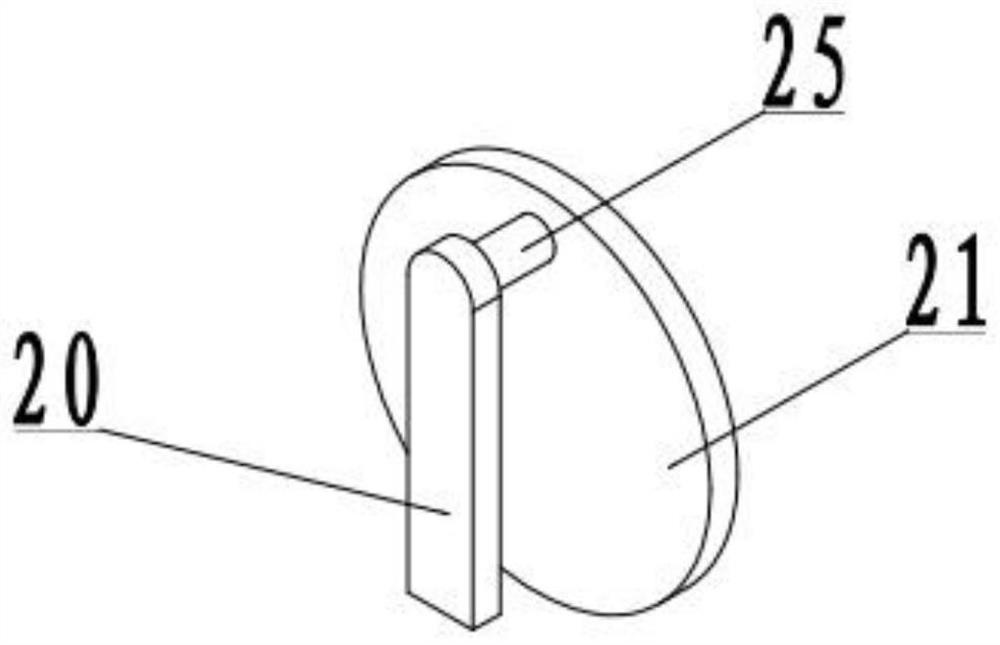

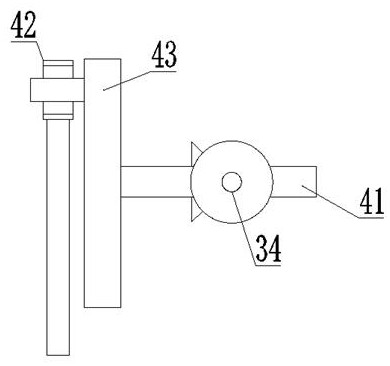

Automatic die rotating and replacing device for bending machine

The invention provides an automatic die rotating and replacing device for a bending machine. The automatic die rotating and replacing device comprises a die turning mechanism and a die backstop and carrying mechanism which are arranged between a left vertical plate and a right vertical plate. A die turning mechanism left rotating wheel disc and a die rotating mechanism right rotating wheel disc are connected with a coupling device through a rigid connection shaft and driven by a right rotating disc shaft drive mechanism, and synchronous rotating of the left rotating wheel disc and the right rotating wheel disc is guaranteed; each rotating wheel disc is provided with a plurality of hanging shafts capable of achieving autoroatation, the hanging shafts correspond to each other in a synchronizing mode on the same station on the two wheel discs, a bending machine die is hung on the rotating wheel discs through the hanging shafts, the two rotating wheel discs are connected with the coupling device through the rigid shaft to achieve synchronous rotating, and the bending machine die is always kept in the vertical position and free of overturning and leftward and rightward moving in the rotating process of the rotating wheel discs; the die backstop and carrying mechanism comprises two blocking fingers playing roles in die positioning and die carrying respectively. The device is economical and practical, easy to operate and high in universality, the die replacing time is saved for users, and production efficiency is improved.

Owner:JINAN CASTING FORGING MACHINERY INST

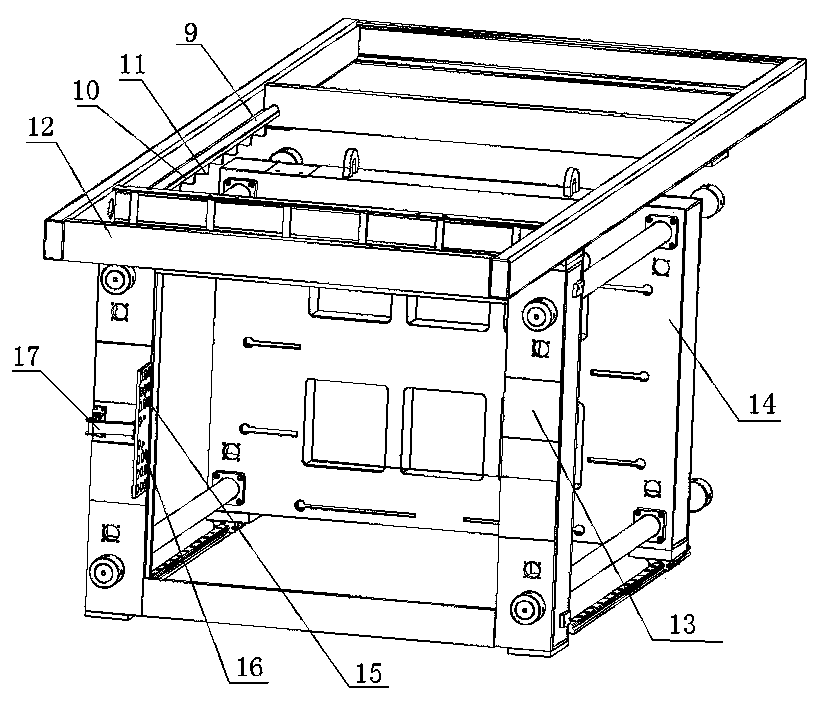

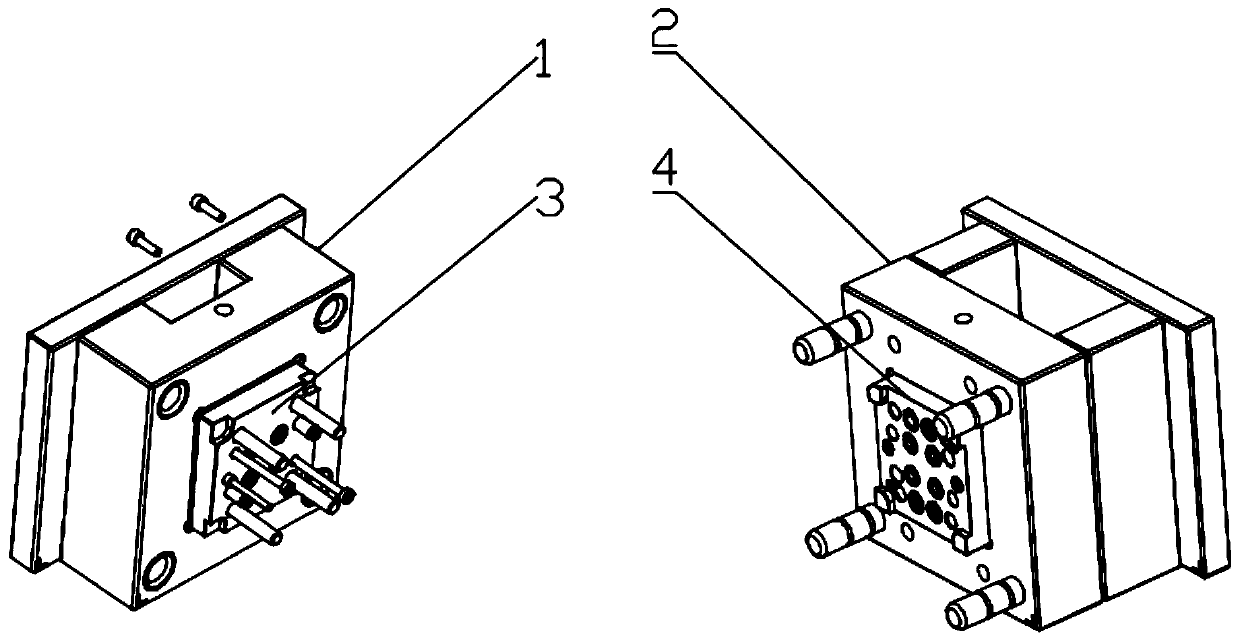

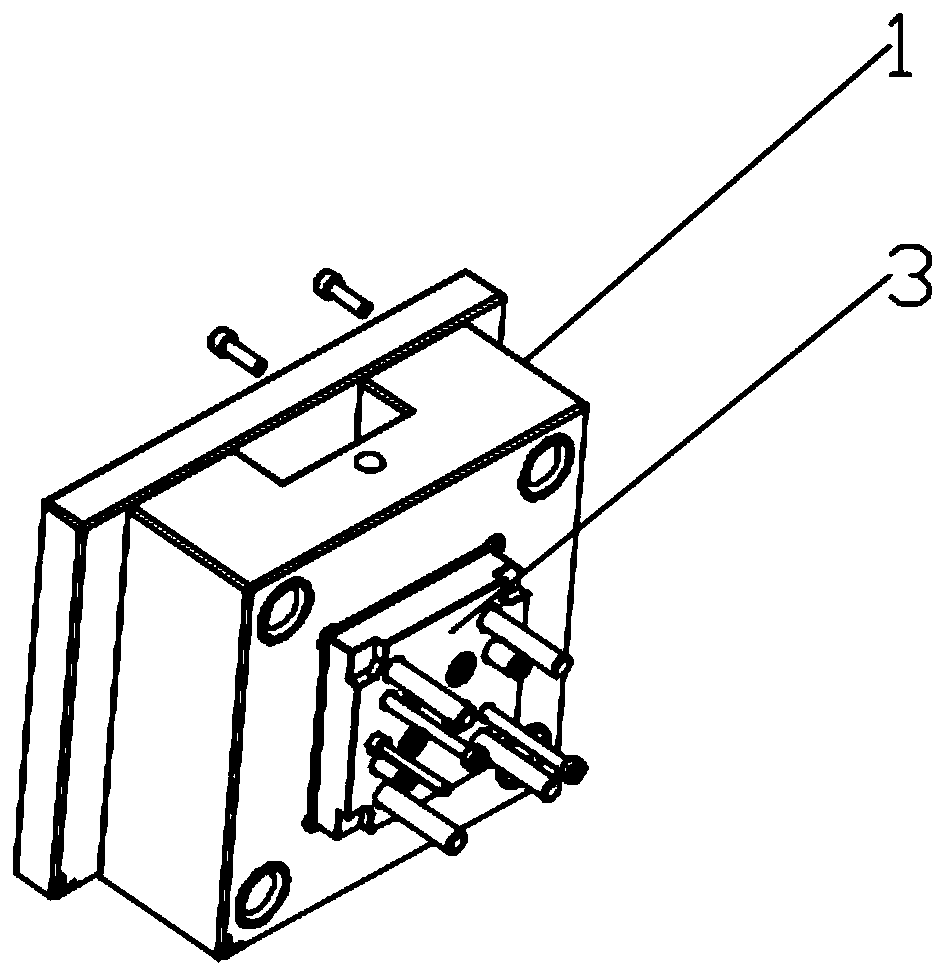

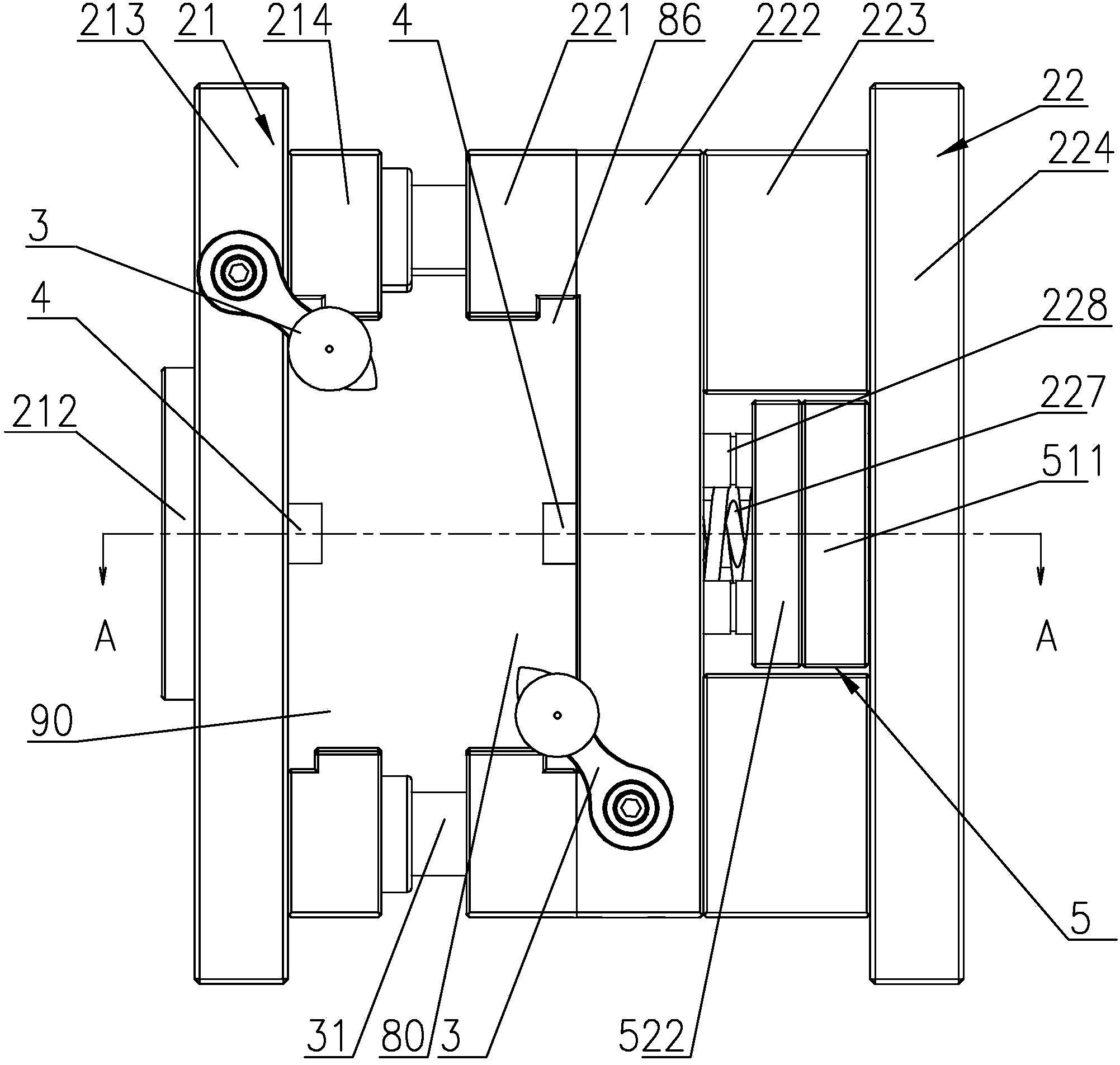

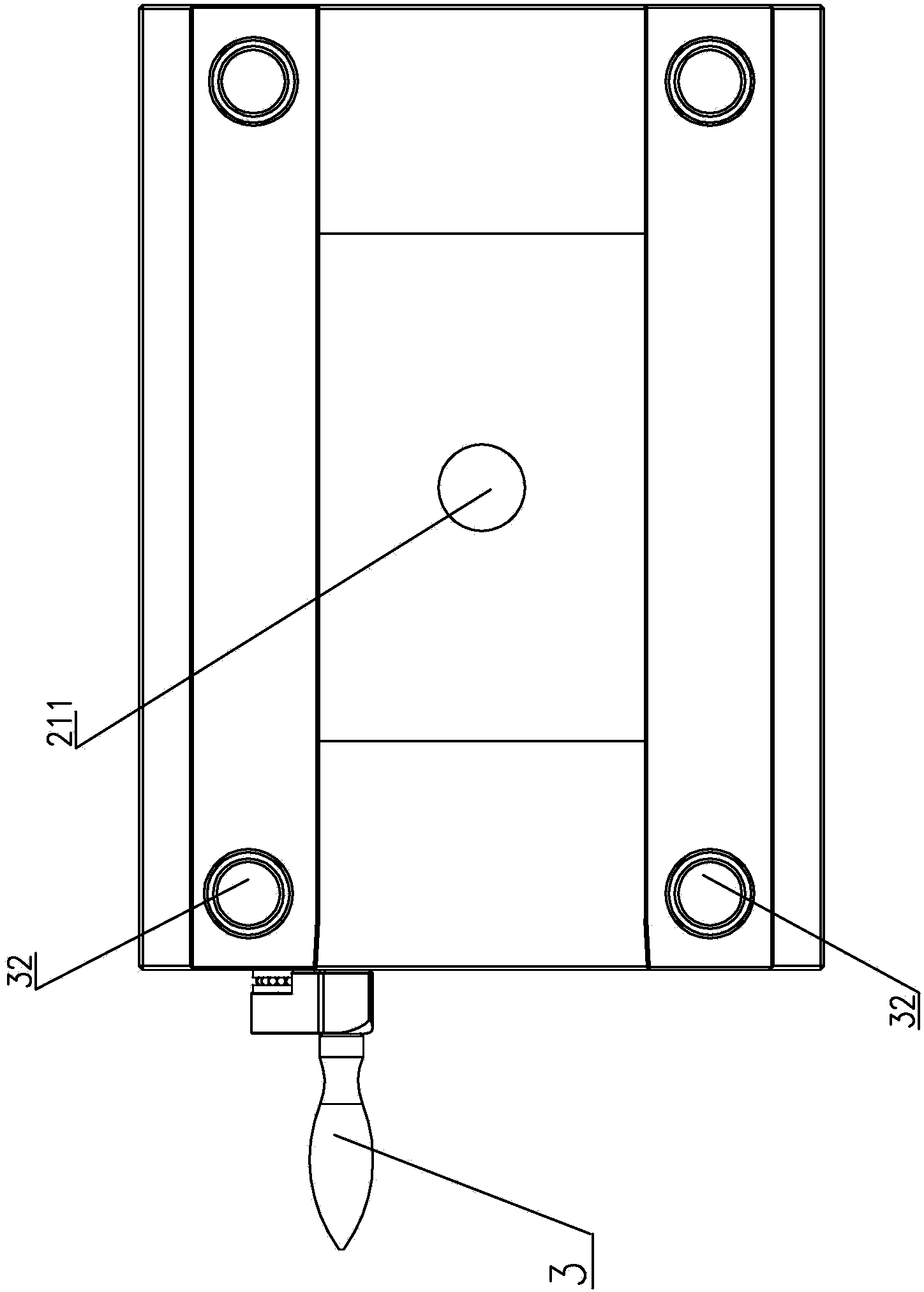

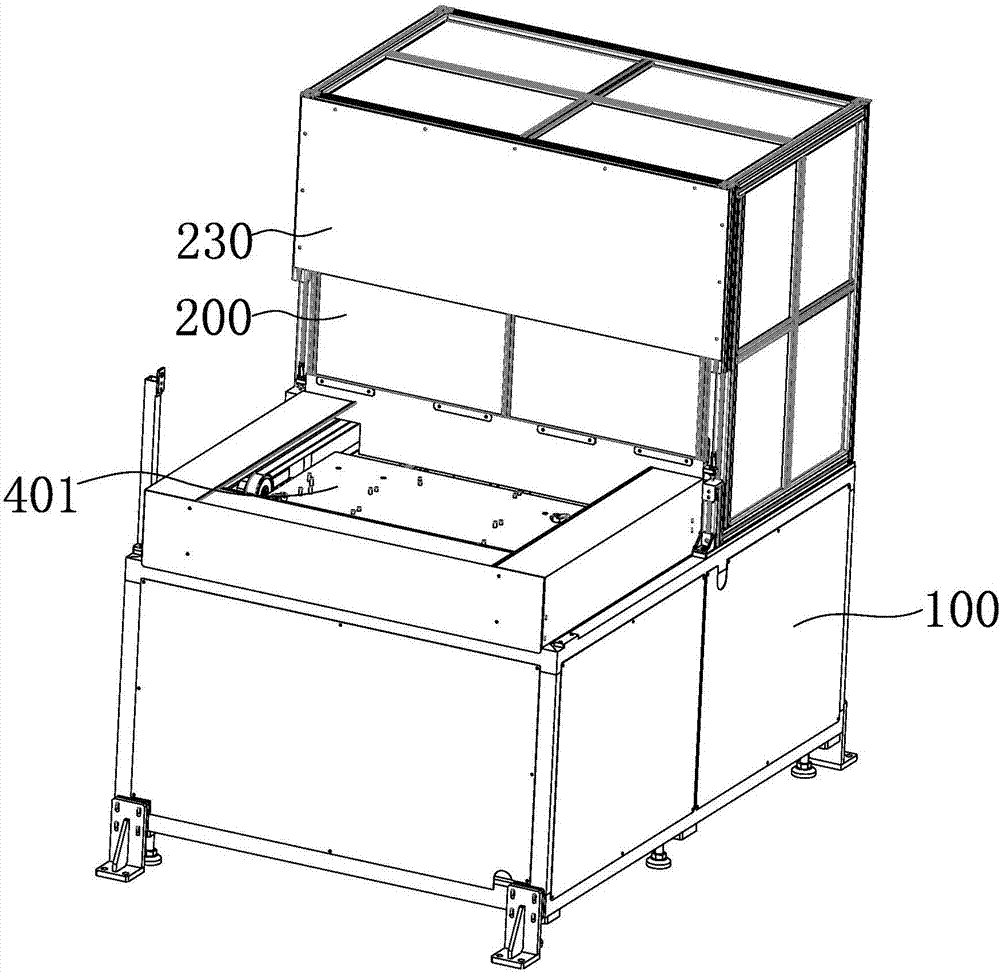

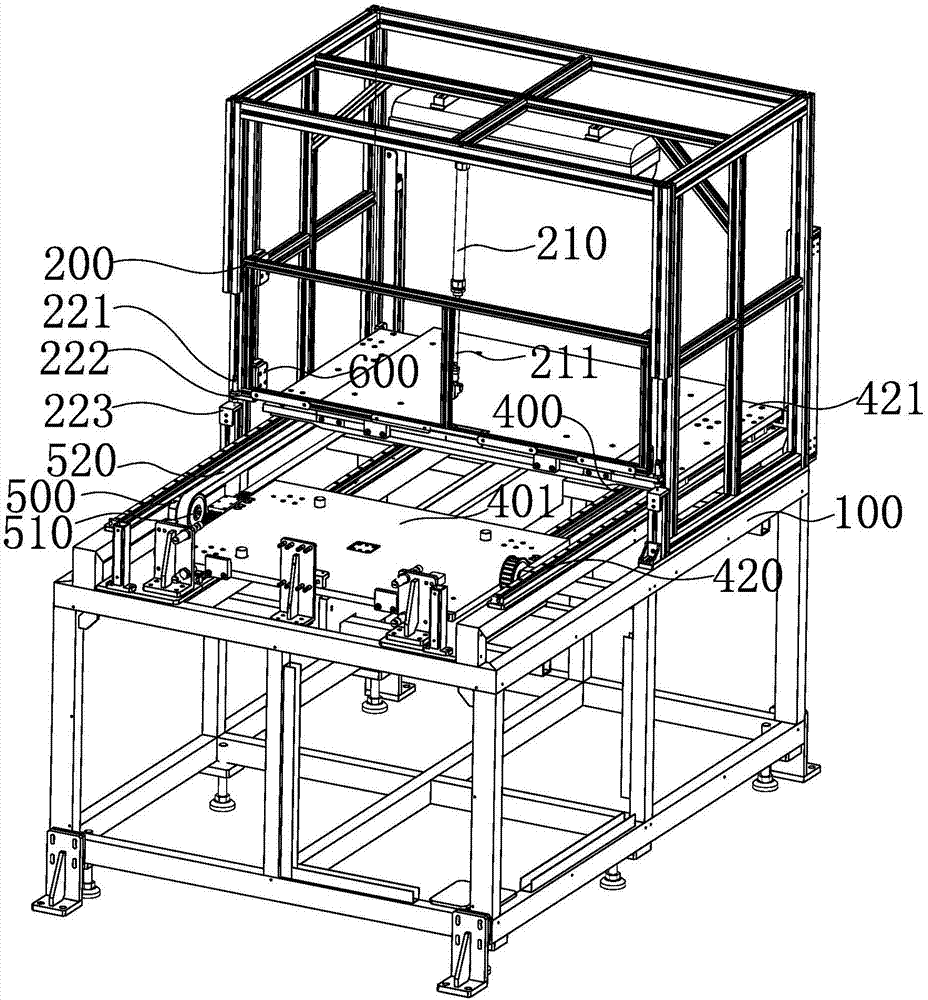

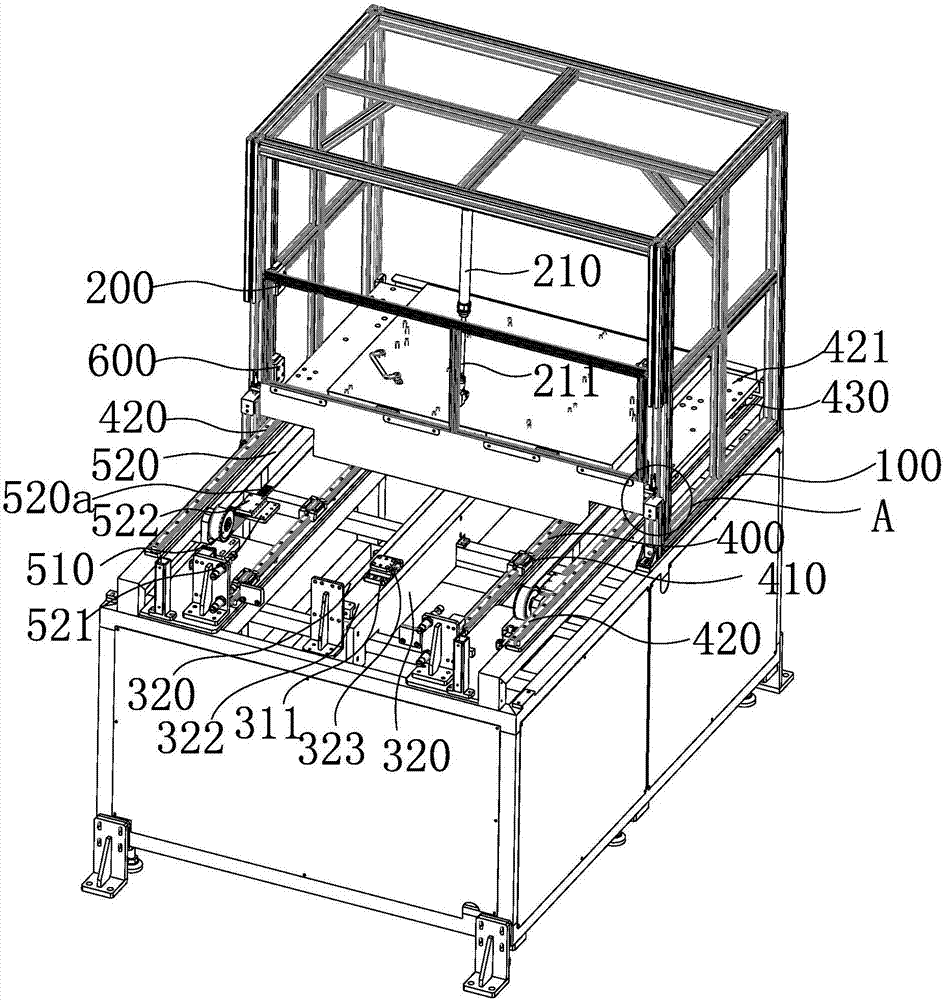

Quick die change device and foam molding machine with quick die change device

PendingCN108274677AReduce replacement timeImprove mold change efficiencyMolding machineMechanical equipment

The invention belongs to the field of mechanical equipment, and particularly relates to a quick die change device and a foam molding machine with the quick die change device. The quick die change device comprises a die change frame, connecting pieces I and connecting pieces II, wherein the die change frame is hollow inside; the connecting pieces I and the connecting pieces II are positioned on thedie change frame; and sliding parts are arranged on the connecting pieces I. The foam molding machine with the quick die change device comprises the quick die change device, a die fixing frame and adie moving frame on a foam molding machine rack, wherein the die fixing frame is fixed to the foam molding machine rack; and the die moving frame is movably connected to the foam molding machine rackand moves front and back relative to the die fixing frame. According to the quick die change device and the foam molding machine with the quick die change device, a die can be changed outside a machine body of the foam molding machine, change of the die is facilitated, time is saved, production efficiency is improved, and operation is simple.

Owner:烟台裕华液力机械有限公司

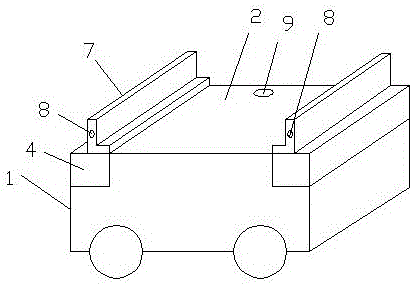

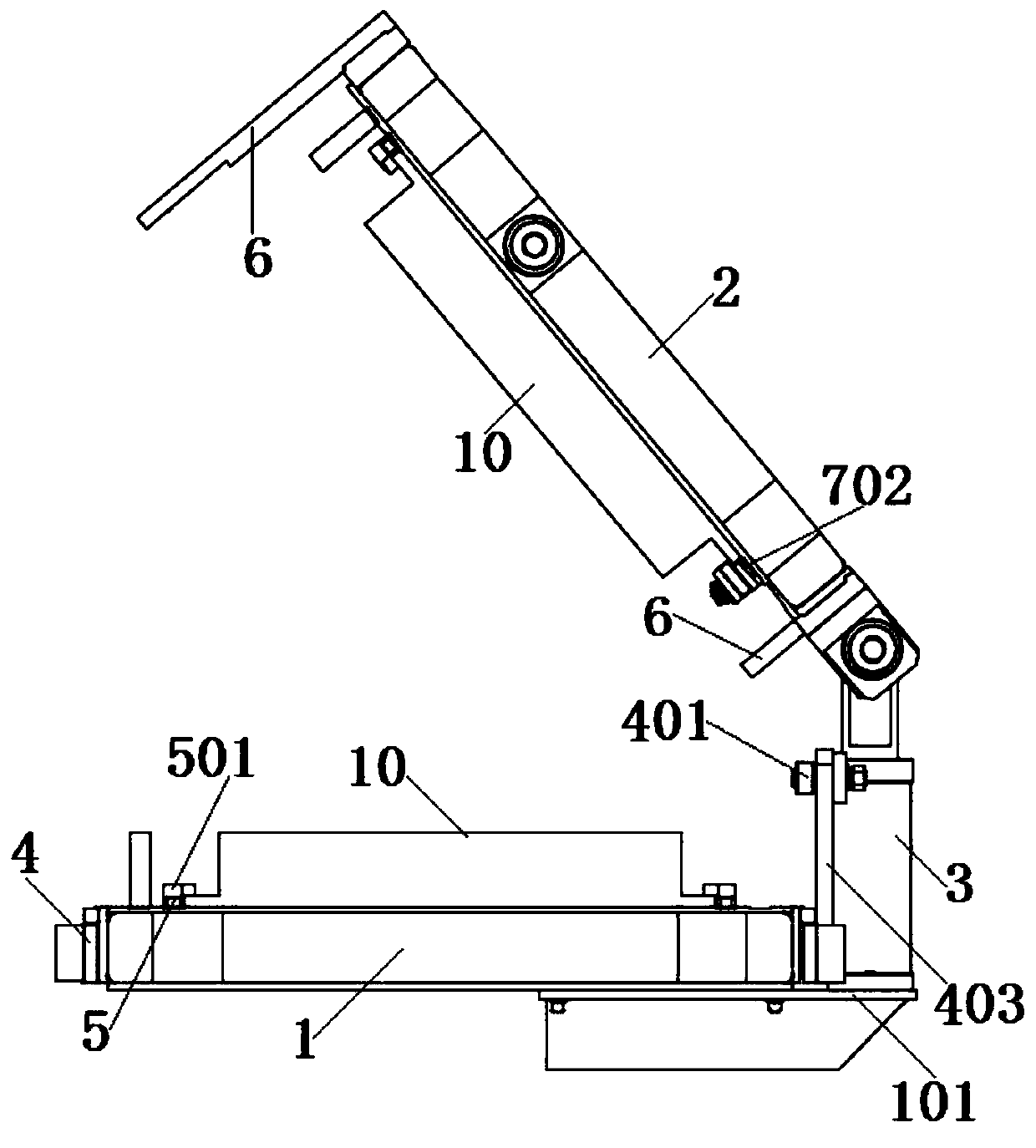

Quick mold change trolley and mold change method thereof

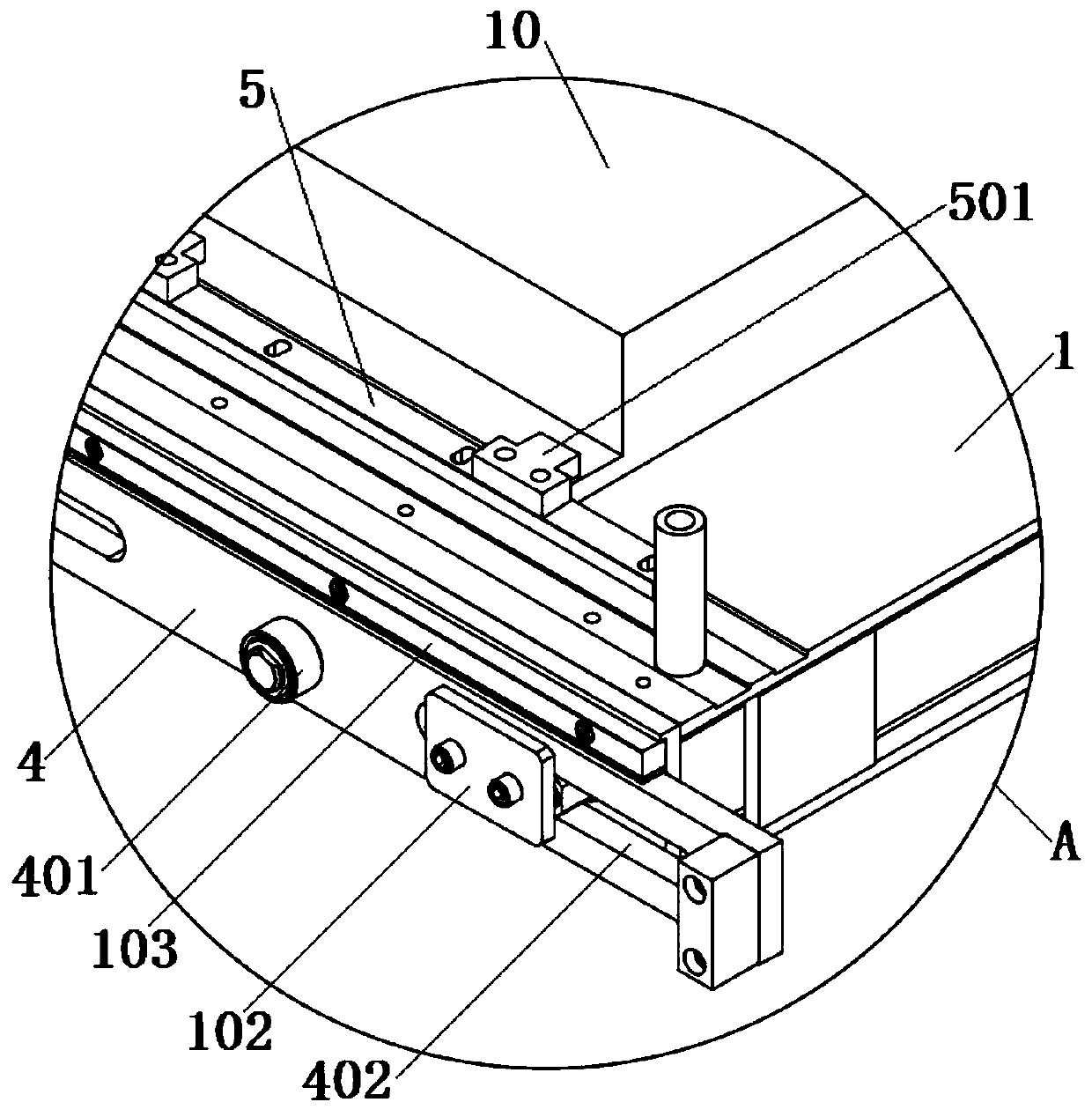

InactiveCN106426666AFriction between the bottom surface of the mold and the table and trolleySmooth mold change processShaping toolsElectrical controlEngineering

The invention discloses a quick mold change trolley and a mold change method thereof. The quick mold change trolley comprises a trolley body; the trolley body includes a bearing surface and a chassis; the trolley body is provided with an electric control system for controlling the mold change process; mounting bases are arranged at two ends of the trolley body; lifting mechanisms are connected between the mounting bases and the trolley body; mold shifting arms are arranged on the mounting bases; horizontal translation mechanisms are connected between the mold shifting arms and the mounting bases; the cross sections of the mold shifting arms are L-shaped; and shoulder steps matched with the mold shifting arms are respectively arranged on two sides of a mold. Compared with the prior art, the quick mold change trolley has the following beneficial effects: the mold is firstly hoisted through the lifting mechanisms; then, the mold is shifted onto the trolley through the translation mechanisms; and in the whole process, no friction is generated among the bottom surface of the mold, a worktable and the trolley, the mold change process is stable, the mold change time is saved, and the mold change efficiency is improved.

Owner:JIANGSU ZHISHI TECH CO LTD

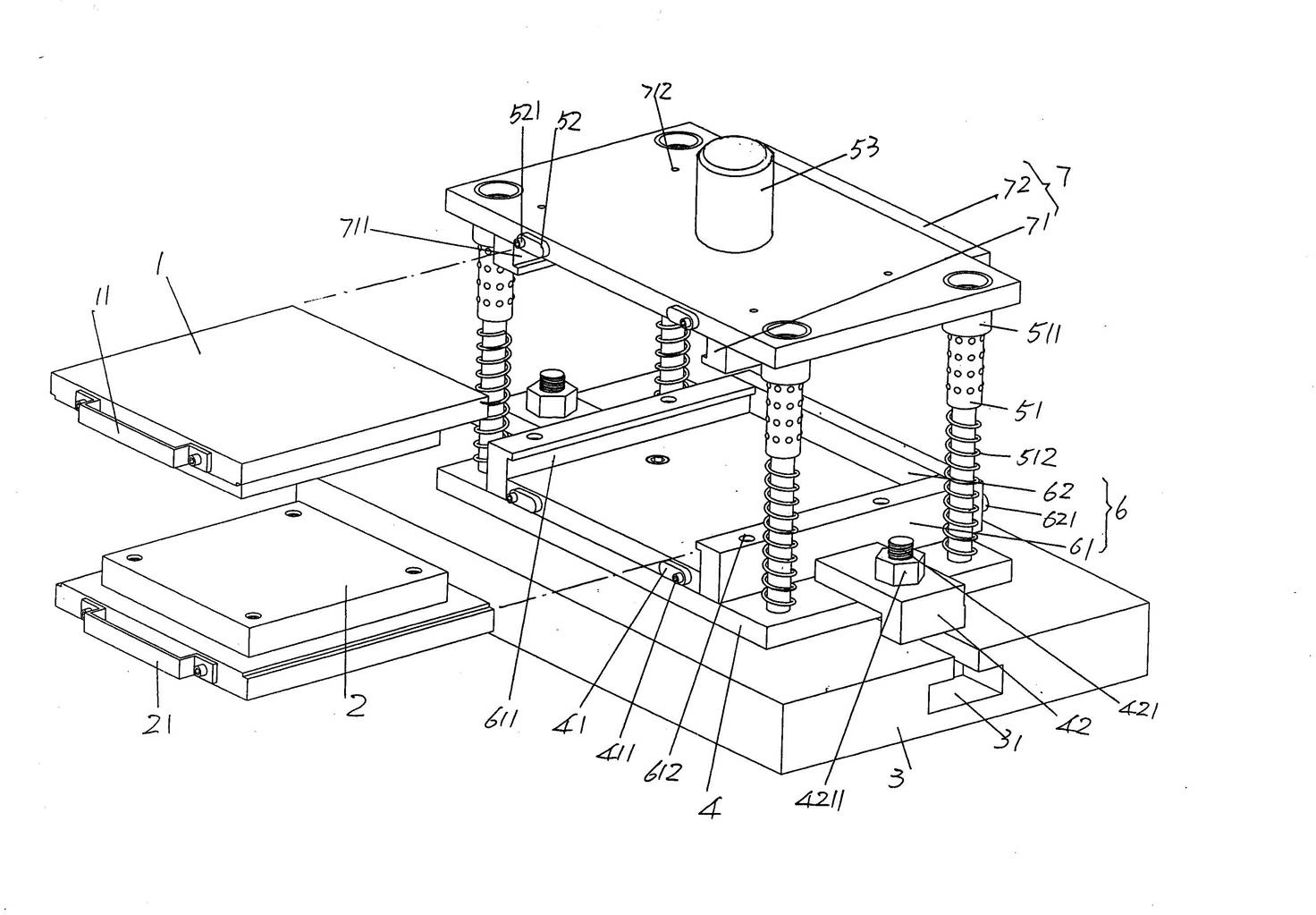

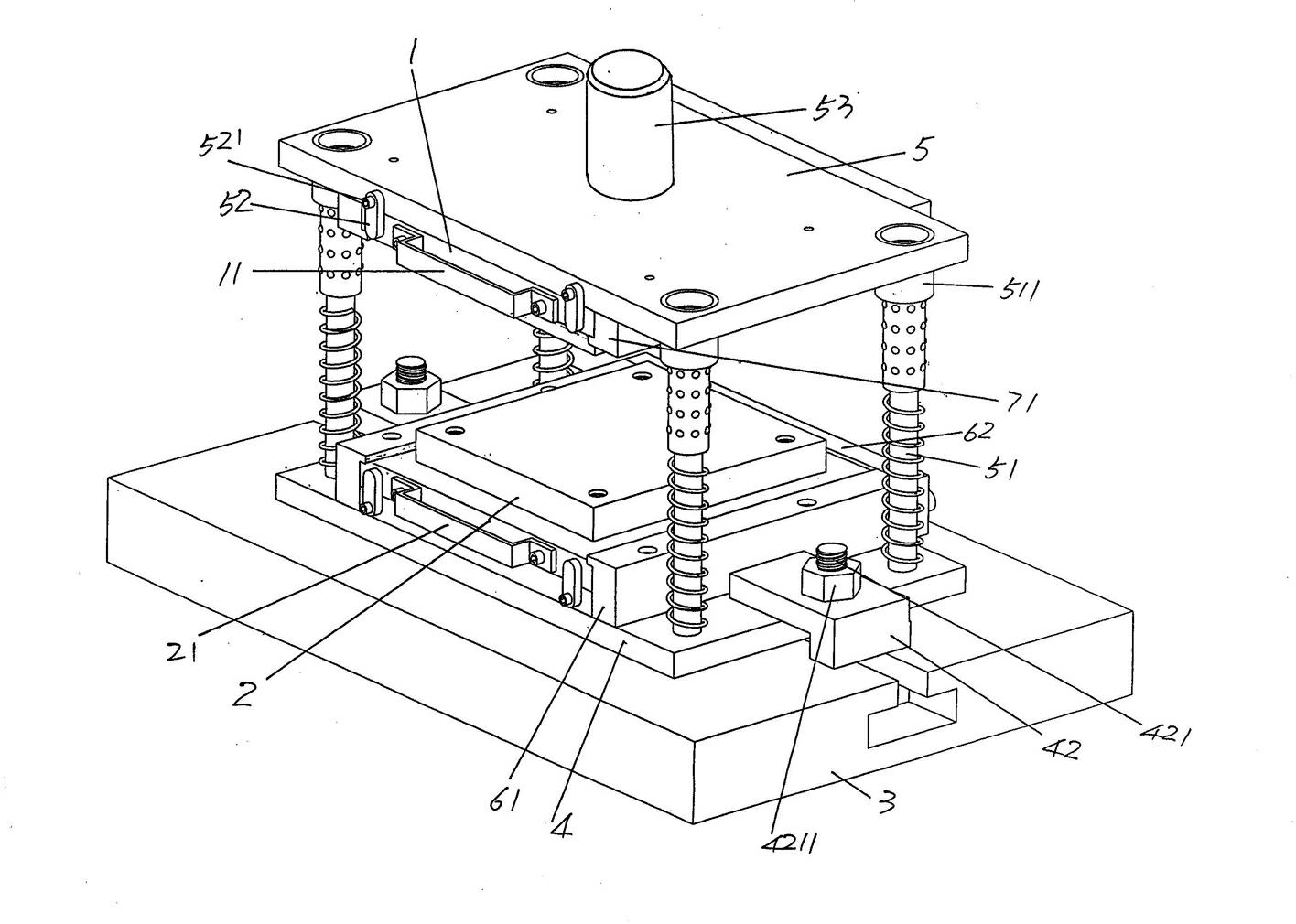

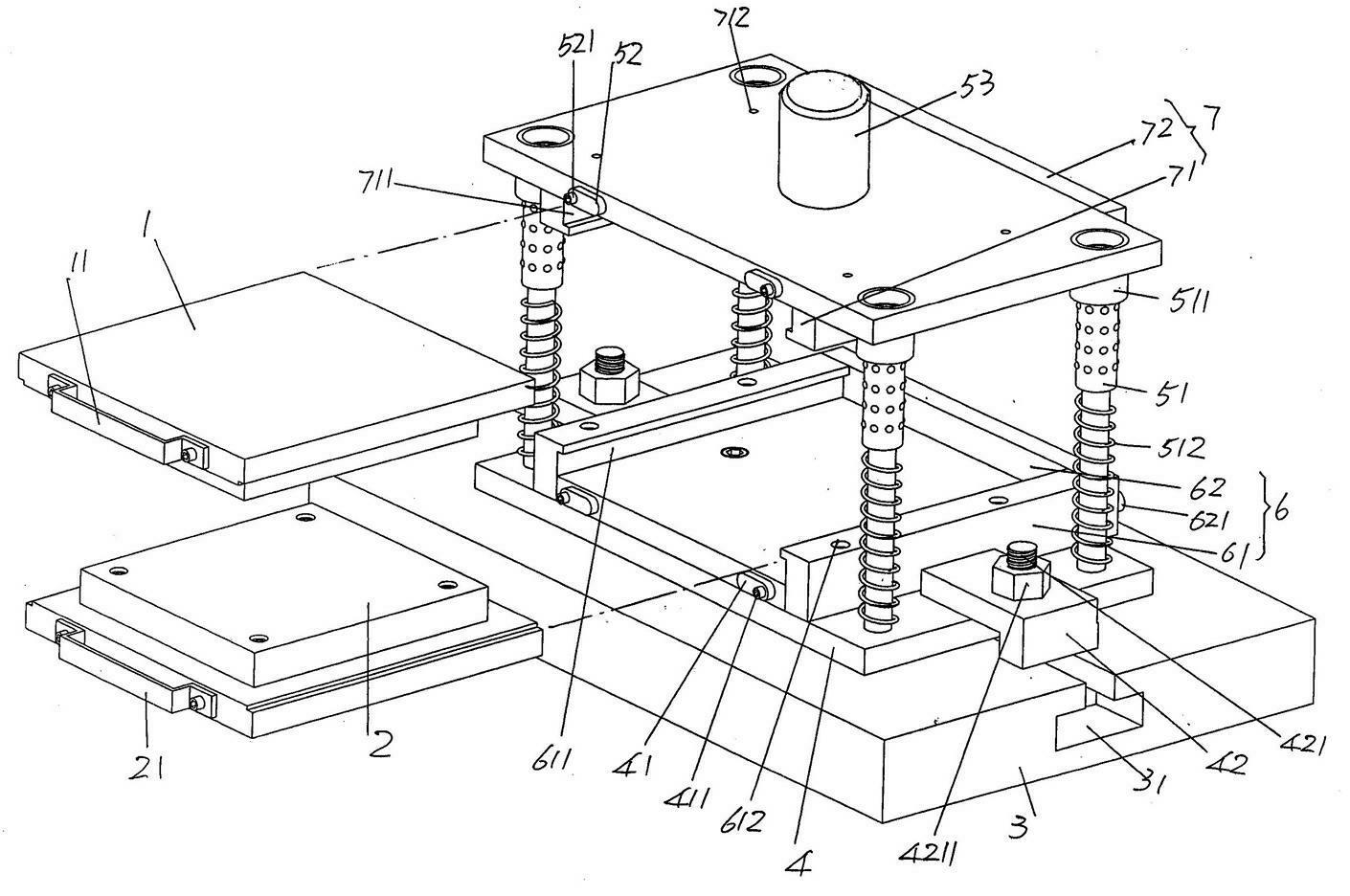

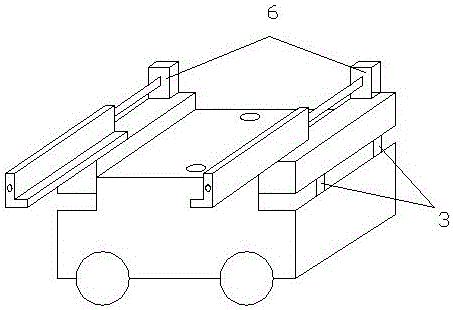

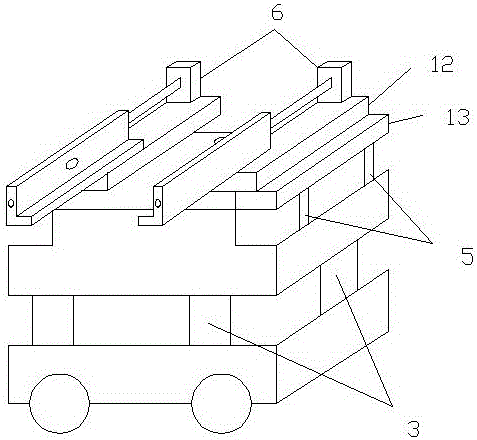

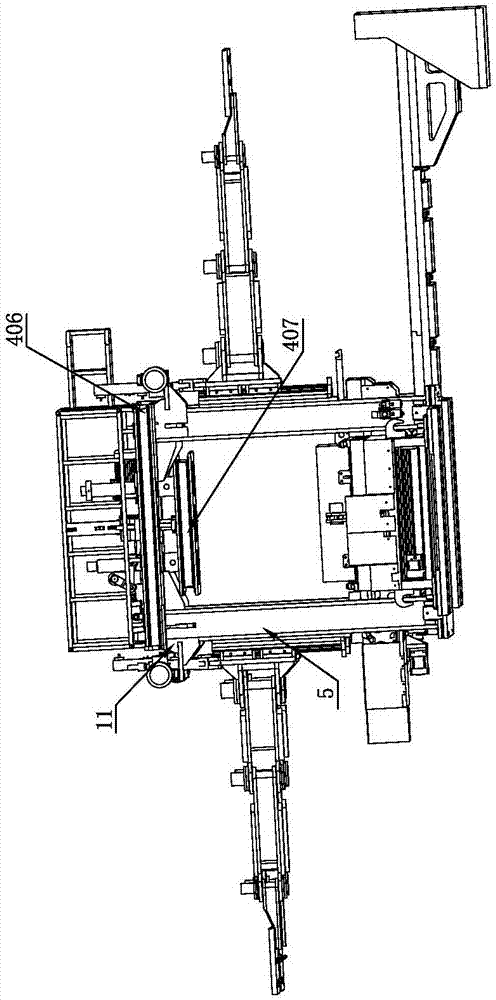

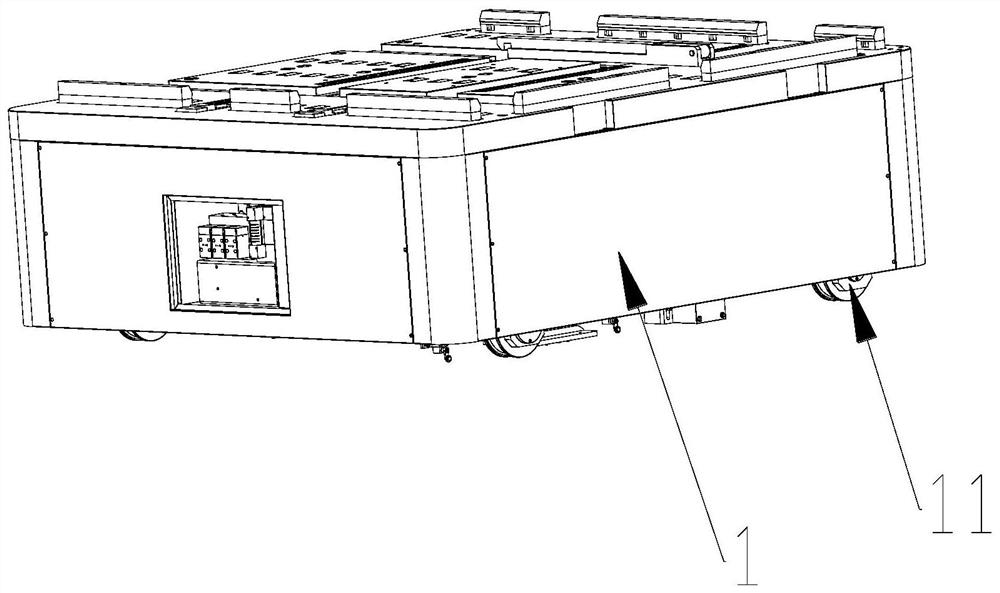

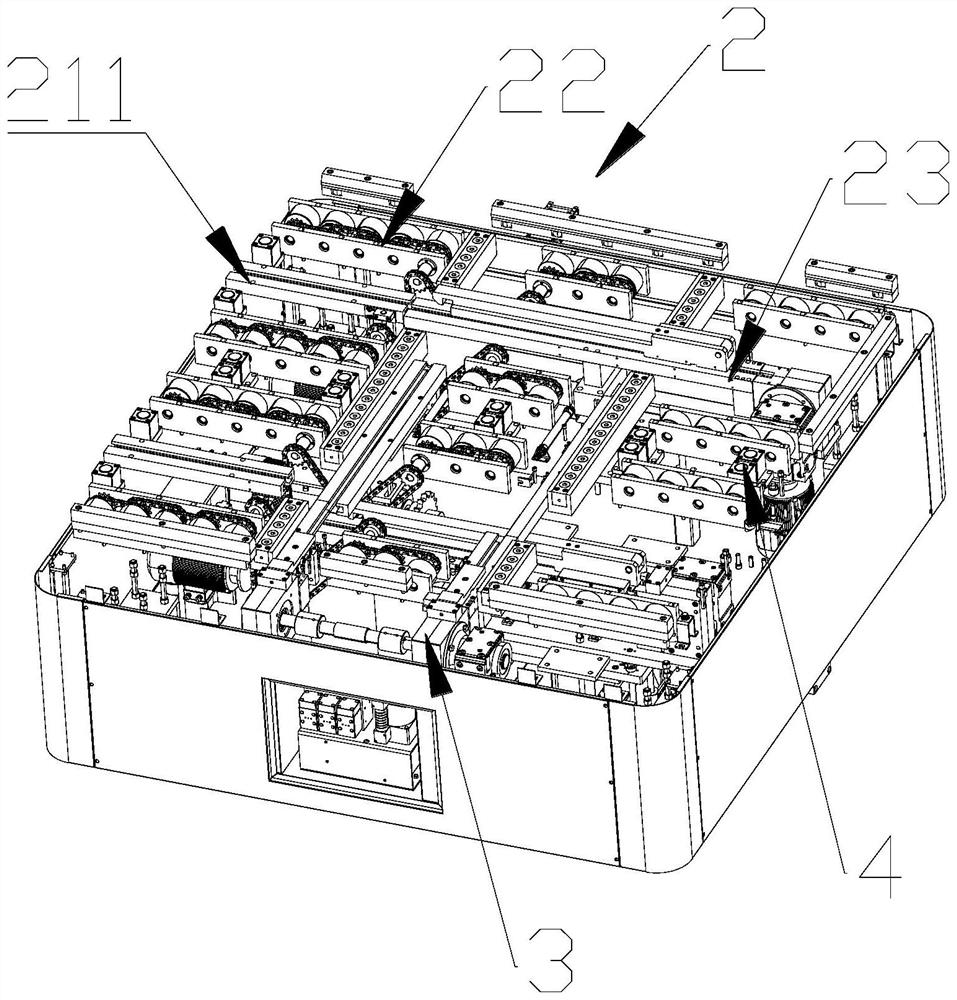

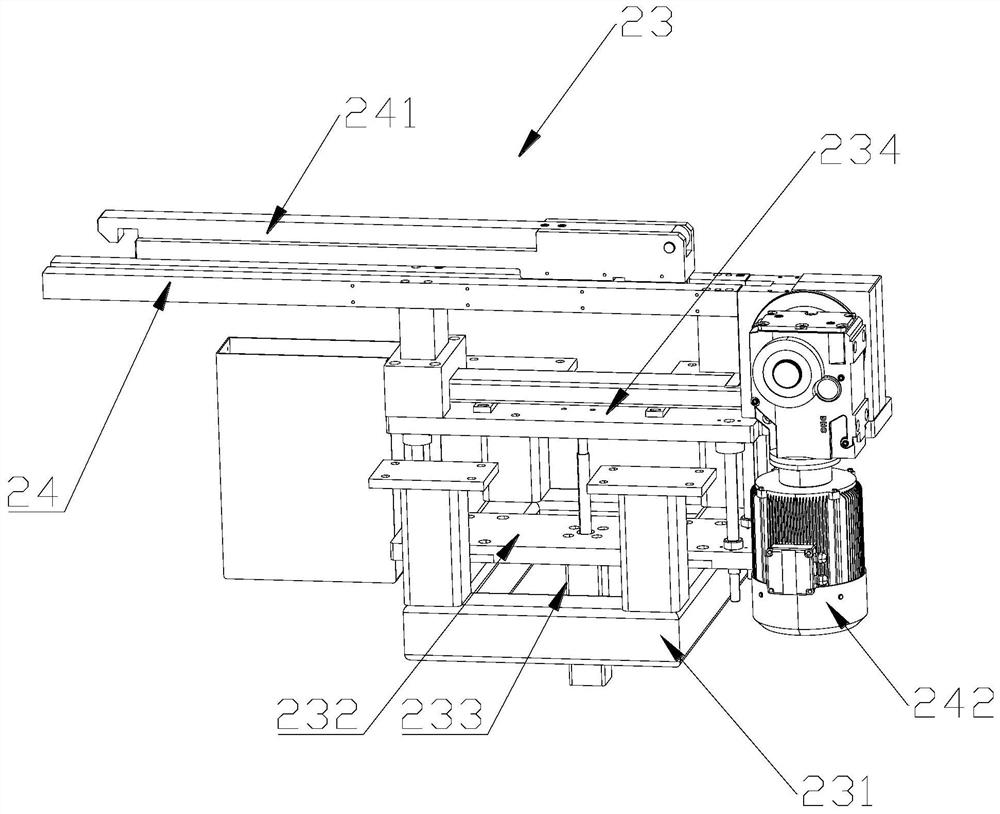

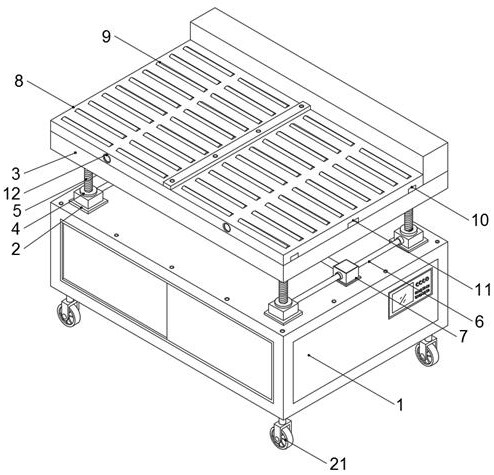

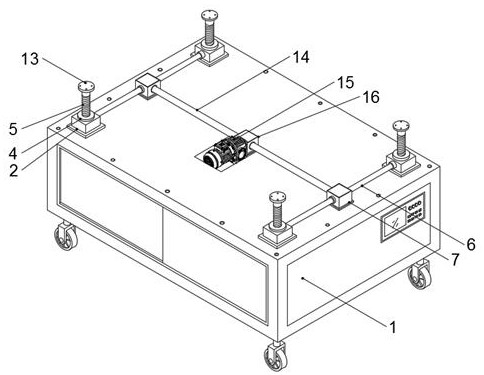

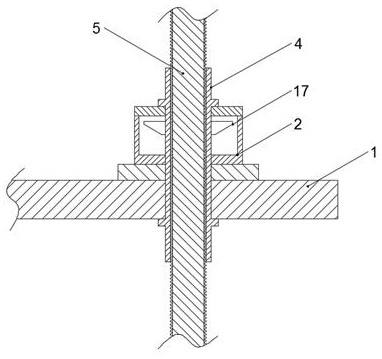

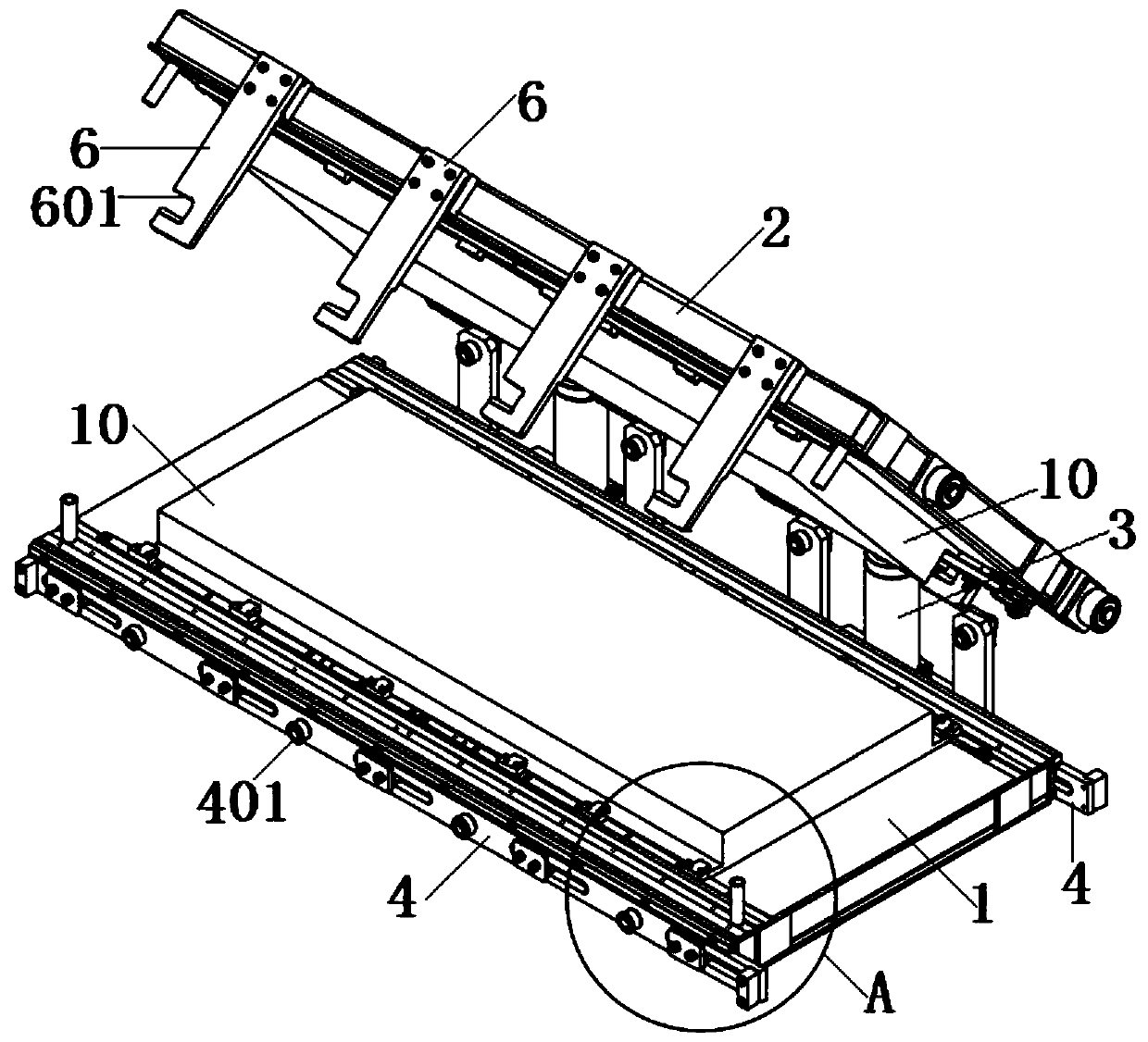

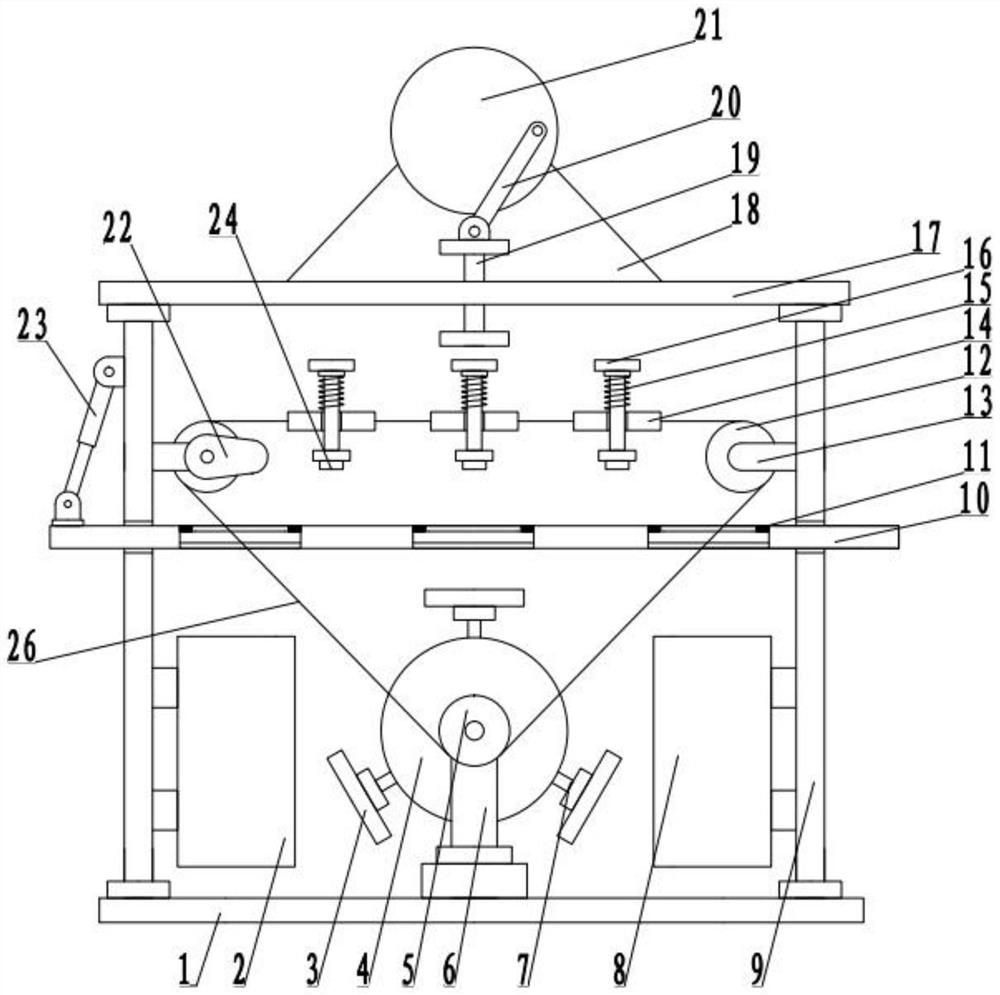

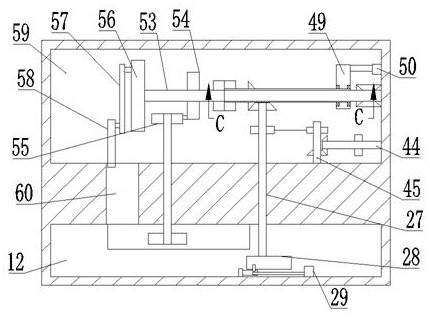

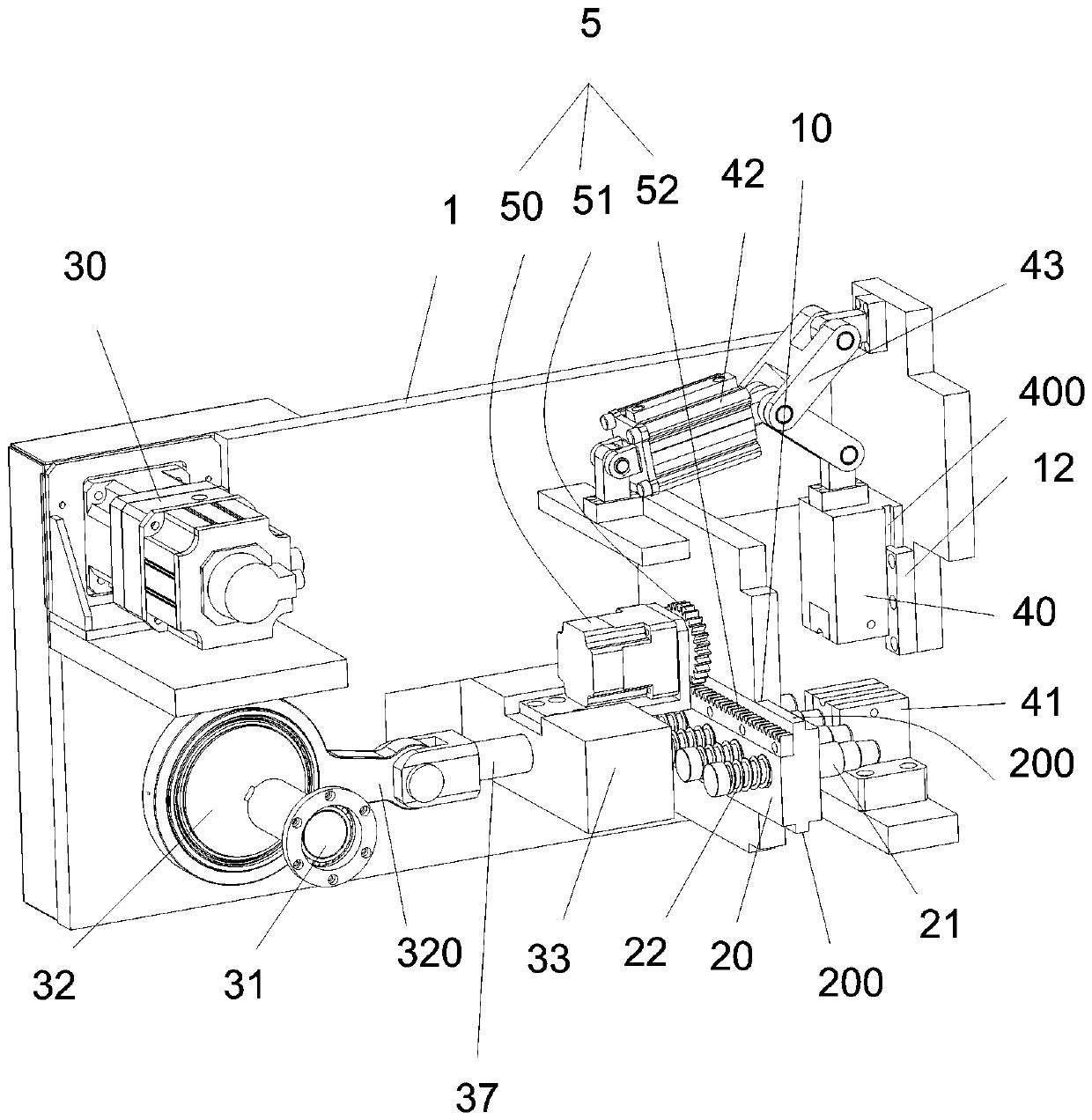

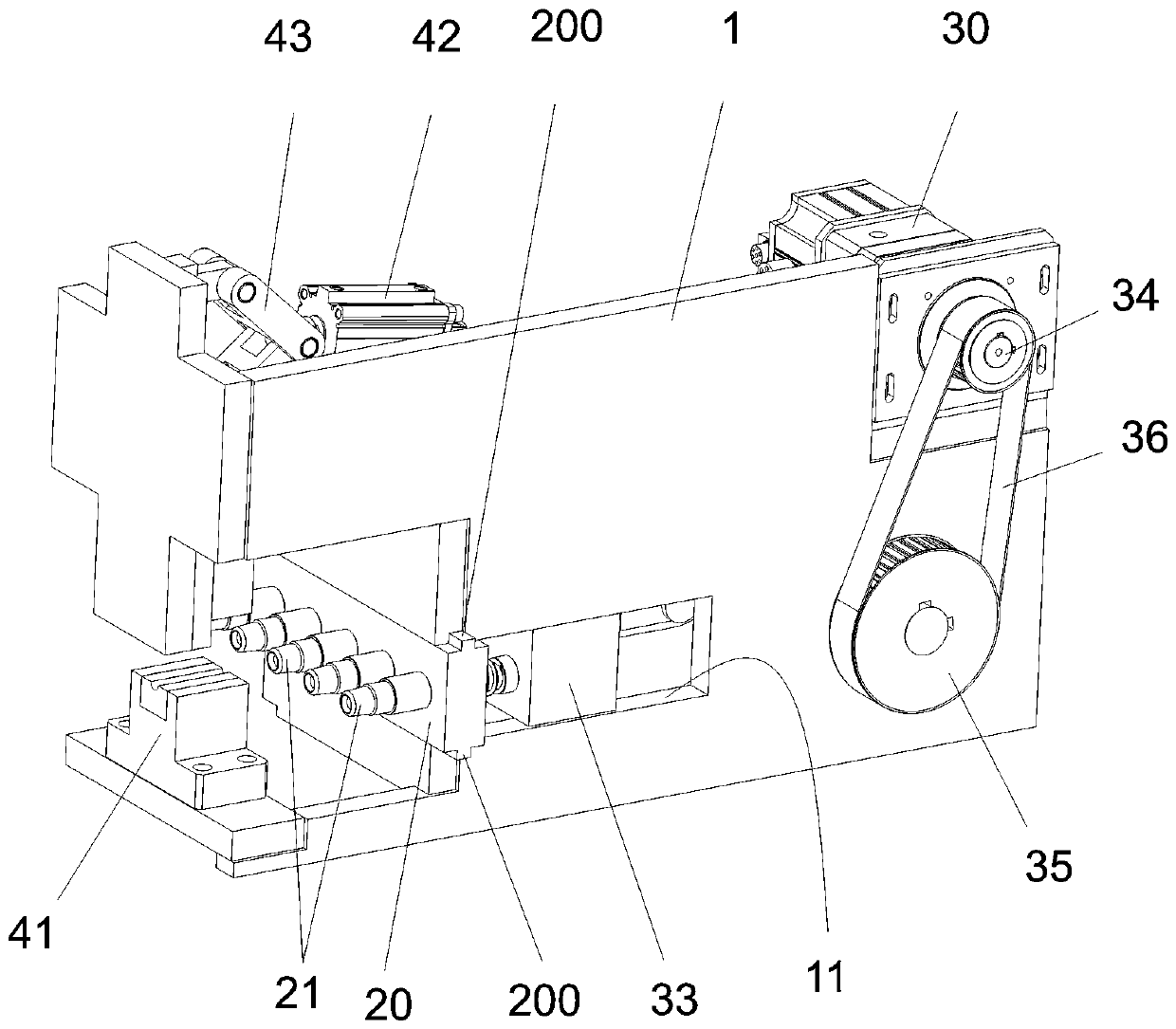

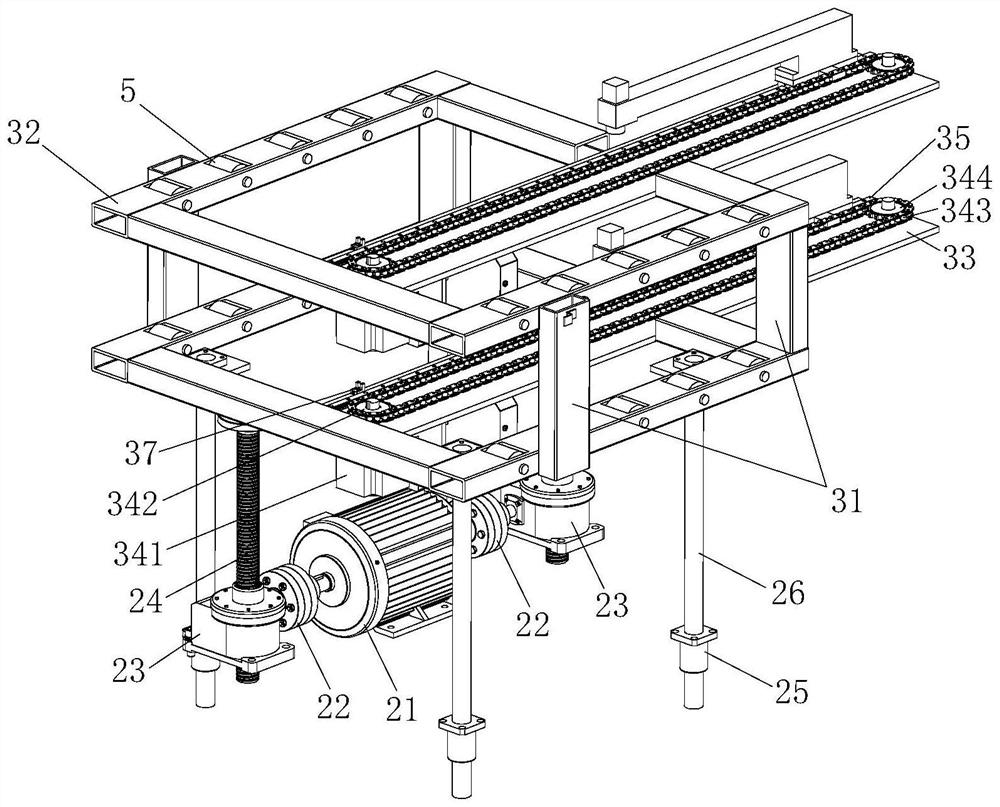

Multidimensional lifting type die changing trolley and die changing method thereof

ActiveCN106552870AFriction between the bottom surface of the mold and the table and trolleySmooth mold change processShaping toolsElectrical controlEngineering

The invention discloses a multidimensional lifting type die changing trolley and a die changing method thereof. The multidimensional lifting type die changing trolley comprises a trolley body. The trolley body comprises a bearing face and a bottom frame. An electrical control system used for controlling the die changing process is configured on the trolley body. The bearing face and the bottom frame are connected through first lifting mechanisms. Installation seats are arranged at the two ends of the trolley body. Second lifting mechanisms are connected between the installation seats and the trolley body. Each installation seat is arranged in a split manner and comprises an upper part and a lower part, wherein a first horizontal moving mechanism is connected between the upper part and the lower part, a die moving arm is arranged on the upper part, and a second horizontal moving mechanism is connected between the die moving arm and the upper part. Compared with the prior art, the multidirectional lifting type die changing trolley and the die changing method thereof have the beneficial effects that a die is lifted through the lifting mechanisms, then the horizontal moving mechanisms move the die to the trolley, no friction happens between the bottom face of the die and a worktable and the trolley in the whole process, the die changing process is stable, in addition, the die changing time is saved, and the die changing efficiency is improved.

Owner:JIANGSU ZHISHI TECH CO LTD

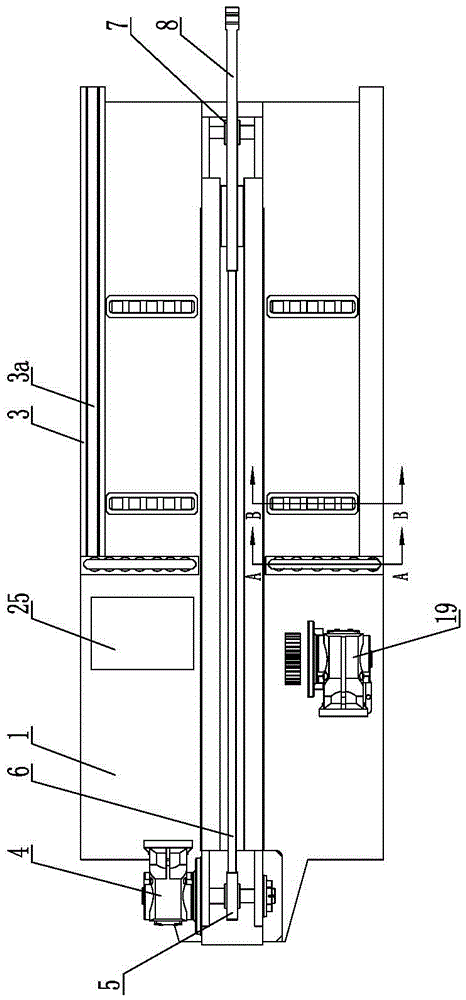

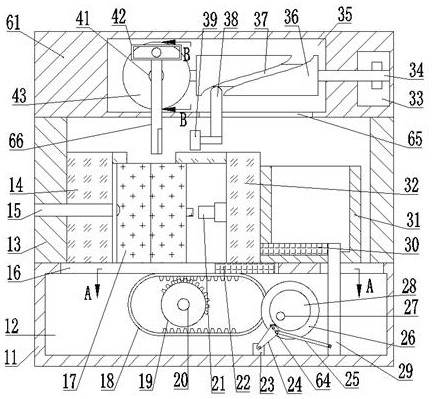

Die changing trolley of press machine and die changing method

The invention discloses a die changing trolley of a press machine in the field of press machines. The die changing trolley comprises a trolley body; the bottom of the trolley body is provided with wheels, the trolley body is provided with a driving mechanism, a pair of die carrier guide rails and a die carrier pushing-pulling mechanism, the die carrier pushing-pulling mechanism comprises a pushing-pulling motor, the output end of the pushing-pulling motor is provided with a belt pulley I, and the belt pulley I is connected with a belt pulley II in a driving way through a belt to which a sliding pothook is connected; the lower part of a die carrier is provided with double rows of die carrier rollers, the trolley body is provided with a die carrier limiting mechanism comprising a base plate, the base plate is provided with a slide wheel axle which is rotatably connected with a side wheel, and the upper end of the side wheel axle is provided with a pressing plate; and the trolley body is provided with a die carrier lifting mechanism in parallel, the die carrier lifting mechanism comprises a roller carrier controlled by a hydraulic cylinder to lift, horizontal rollers are horizontally arranged on the roller carrier, and roller shafts of the horizontal rollers are parallel to the die carrier guide rails. By using the die changing trolley, the die carrier of the press machine can be rapidly changed, the die changing time can be shortened, and the die changing efficiency can be increased.

Owner:YANGLI GRP CORP LTD

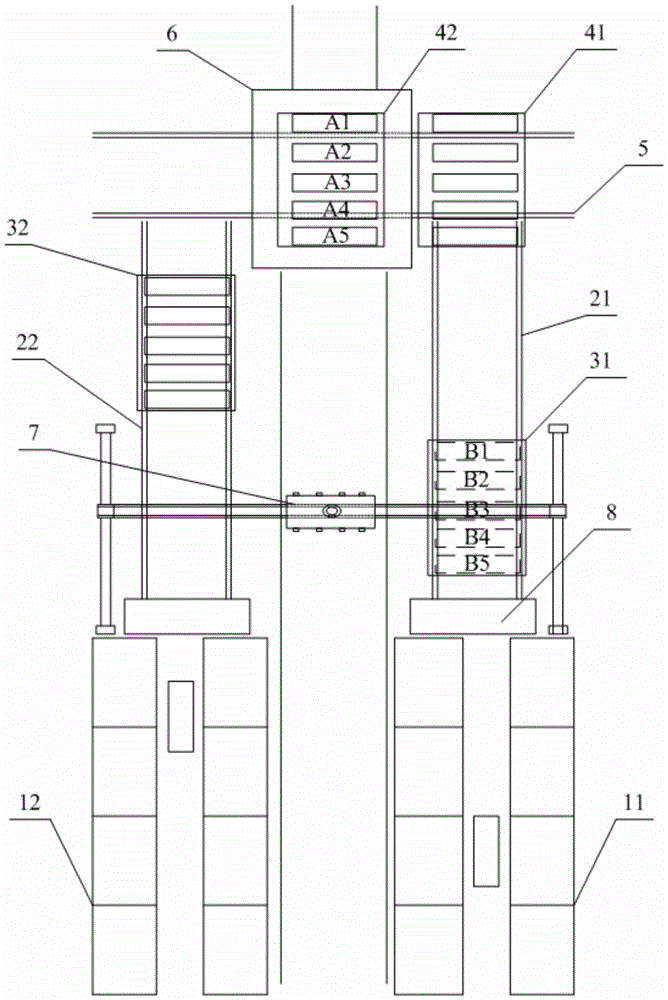

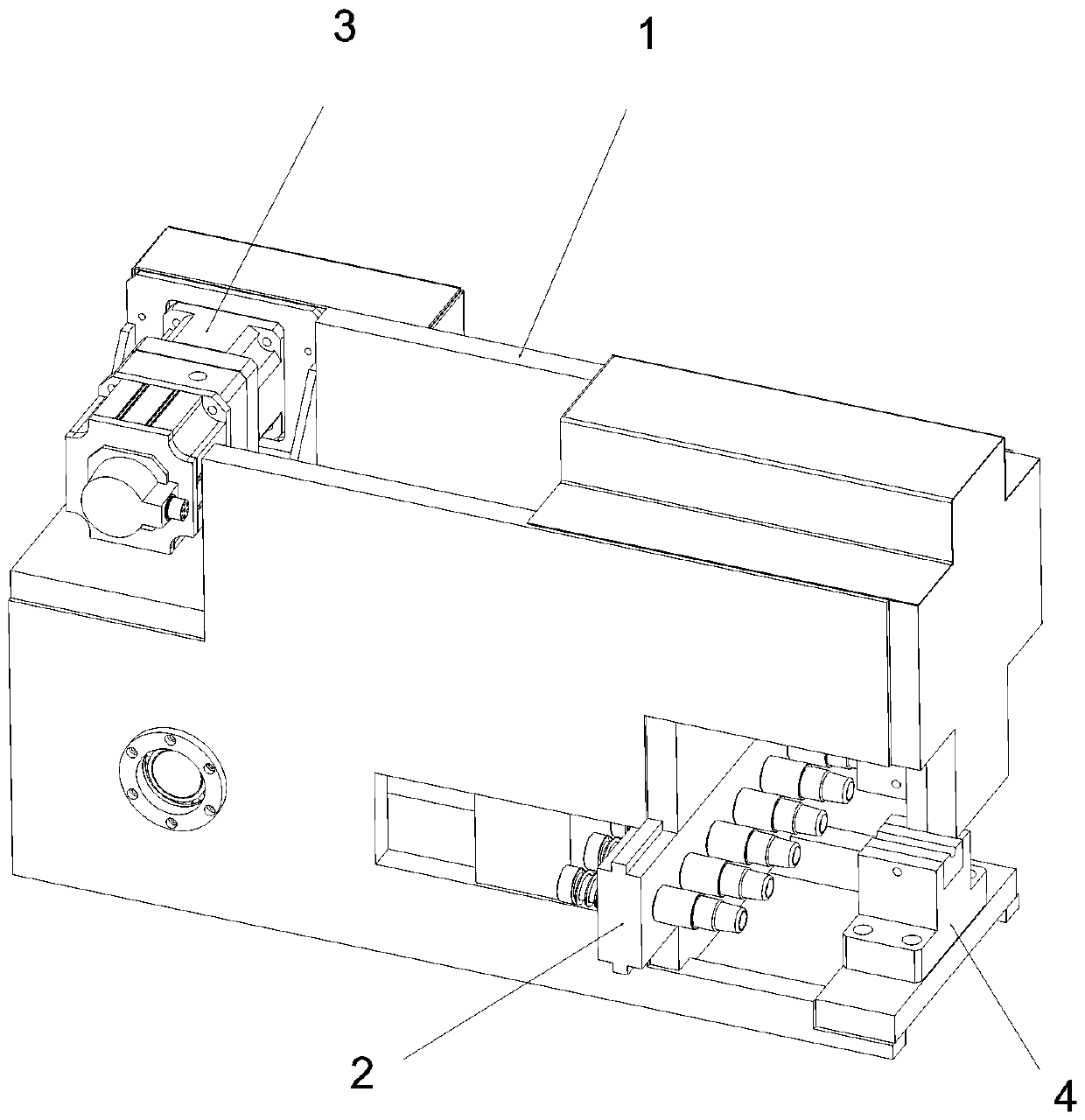

Press machine die changing device

The invention provides a press machine die changing device applied to the field of die changing machinery. The press machine die changing device comprises a die changing trolley and a die changing platform. The die changing trolley comprises a trolley frame used for storing die sets. Rolling wheels are arranged at the bottom of the trolley frame. The trolley frame is internally provided with a driving mechanism. The driving mechanism drives the die changing trolley to travel on a track matched with the rolling wheels. The die changing platform comprises four stand columns, transmission devices and a lifting device, wherein the four stand columns are arranged to be in a rectangular shape, and the lifting device is used for lifting the upper die set. Two or more of the stand columns are connected with the transmission devices, wherein the transmission devices can ascend, descend and be bent automatically. The transmission devices can extend to a press machine workbench. The two ends of the die changing trolley are each provided with a die set bank, wherein each die set bank is used for storing the corresponding die set. The die set banks are perpendicular to the movement direction of the die changing trolley. The track extends to the front side of a press machine. The press machine die changing device is high in automation degree and die changing efficiency.

Owner:YANGLI GRP CORP LTD

Module holder moving device of vertical extruder and vertical extruder

ActiveCN102962278AEasy to operateReduce labor intensityExtrusion profiling toolsEngineeringMechanical engineering

The invention provides a module holder moving device of a vertical extruder and a vertical extruder. The moving device comprises a push-pull device and a guide rail, wherein the guide rail extends from an operation position to a detach position; the operation position is located above the discharge hole of one operation surface of an extruder base; the detach position is located on the outer side of the extruder base; and the push-pull device can drive a module holder to move to the operation position or the detach position along the guide rail. Compared with the prior art that a module can be detached only by hands, the module holder moving device provided by the invention can drive the module holder to move to the detach position outside the extruder along the guide rail by using the push-pull device; and the module in the module holder can be lifted by a crane after the module holder moves out of the extruder so as to obviate manual conveying. Moreover, the module base can be pushed back to the operation position by the push-pull device rapidly after being provided with a new module. Accordingly, the device provided by the invention can be used for facilitating the movement of the overall module holder, reducing the labor intensity and improving the module changing efficiency.

Owner:TAIYUAN HEAVY IND

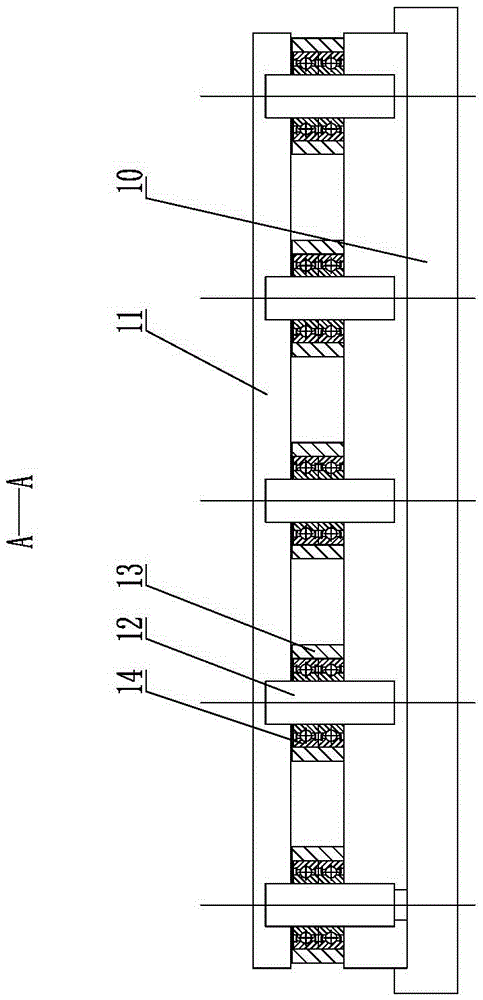

Automatic die changing device of bending machine

InactiveCN104399826AReduce labor intensityHigh degree of automationShaping toolsEngineeringDrive motor

The invention relates to a bending machine, in particular to an automatic die changing device of the bending machine. The automatic die changing device of the bending machine comprises a slide block, and a clamping device is arranged at the lower end of the slide block; the slide block is provided with at least two suits of chain drive devices in parallel, each chain drive device comprises chain wheels and an annular chain engaged to the chain wheels, the chain wheels are connected with a drive motor through a rotating shaft, the annular chain vertically winds the slide block, the annular chain is provided with a plurality of connecting components, the connecting components are hinged to a die handle, the slide block is provided with a lifting lead rail, the connecting components are in sliding connection with the lifting lead rail, and the lifting lead rail is connected with a longitudinal move device. The automatic die changing device of the bending machine has beneficial effects that the automatic degree is high, the die change efficiency is improved, and the labor intensity of the operators is lowered; the structure is reasonable, the service life is long, because the connecting components are hinged to the die handle, the die and die handle always locate at a vertical state under the gravity, and therefore, the space usage is small.

Owner:惠民县瑞平科技服务有限公司

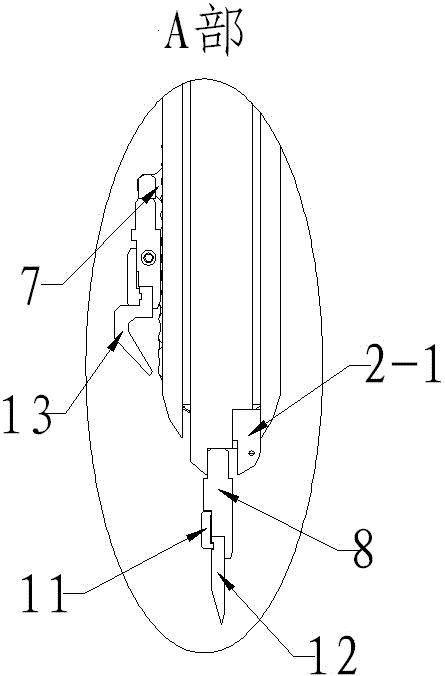

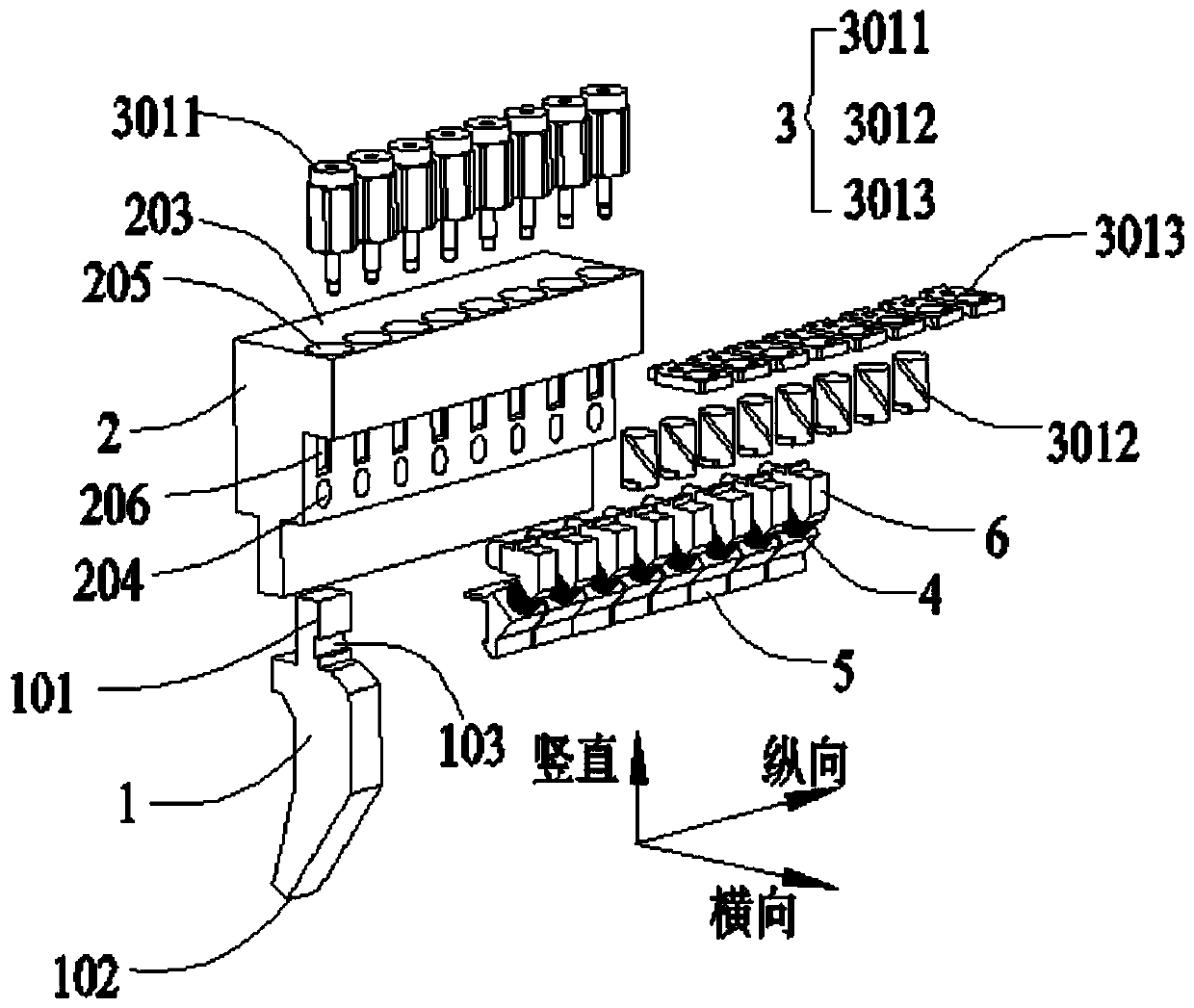

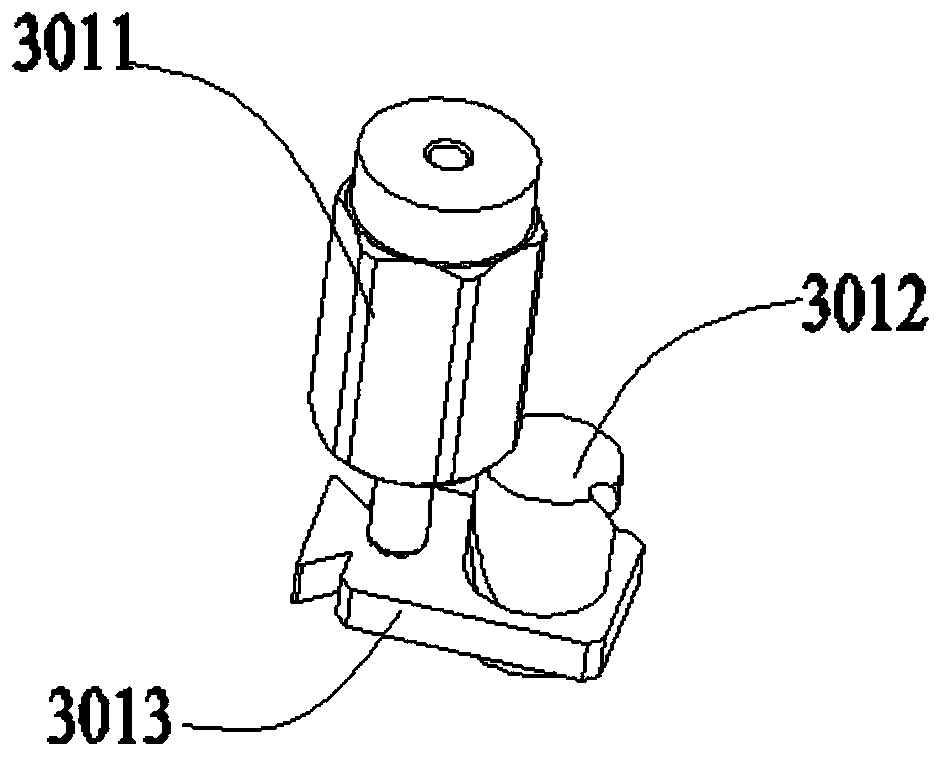

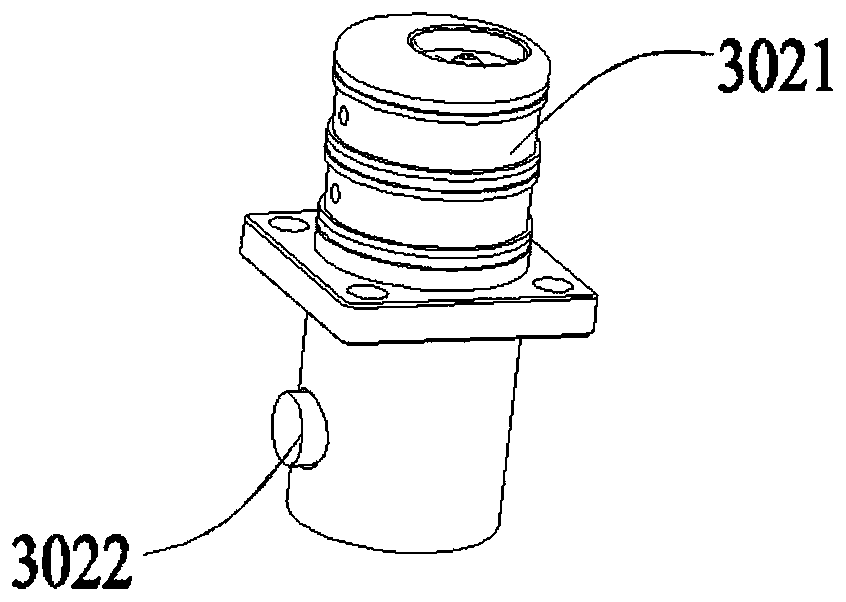

Locking mechanism and bending die quick clamping system including locking mechanism

PendingCN111167949AClamp evenlyEliminate incomplete clamping of moldsShaping toolsShaping safety devicesClassical mechanicsEngineering

The invention discloses a locking mechanism and a bending die quick clamping system including the locking mechanism. The locking mechanism comprises a mounting base and one set or more sets of clamping execution assemblies, the one set or more sets of clamping execution assemblies arranged in the longitudinal direction are provided on the one transverse side or two transverse sides of the mountingbase, a mold is clamped between the clamping execution assemblies and the mounting base, and the clamping execution assemblies are close to or away from the mounting base in a plane perpendicular tothe longitudinal direction; and the adjacent clamping execution assemblies are arranged next to each other. The locking mechanism and the bending die quick clamping system including the locking mechanism can completely eliminate the situation that the mold cannot be completely clamped when the clamping position slightly changes due to mold machining errors or mold abrasion and other reasons (potential safety hazards can occur), it is guaranteed that any segment of the mold at the any mounting position on the mounting base is uniformly and consistently clamped, and the clamping force is not degraded.

Owner:王勇

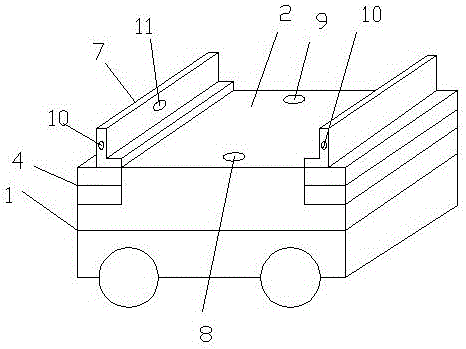

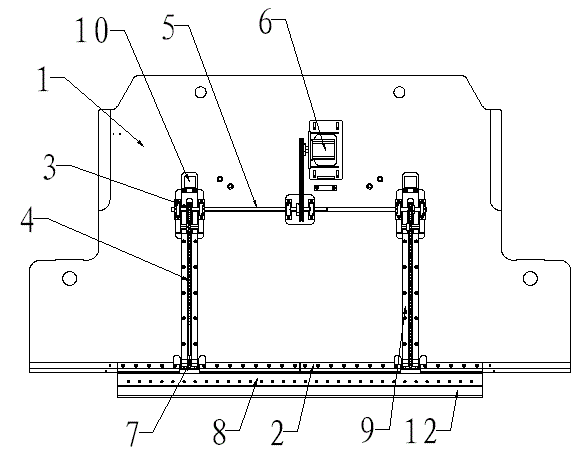

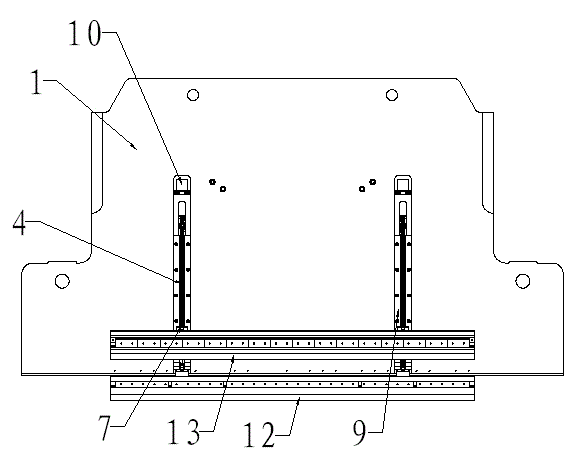

Double-station die changing trolley

PendingCN111687321AImprove work efficiencySmall footprintShaping toolsElectric machinerySmall footprint

The invention discloses a double-station die changing trolley. The double-station die changing trolley comprises a trolley body, a first station and a second station are installed on the trolley body,the first station comprises a double-power die changing mechanism, the double-power die changing mechanism comprises a lifting push-pull mechanism and roller mechanisms located on the two sides of the lifting push-pull mechanism, the double-station die changing trolley further comprises a push-pull mechanism perpendicular to the double-power die changing mechanism, a die positioning block and a first motor for driving the positioning block to ascend and descend are arranged between the first station and the second station, and the second station and the first station are of the same structure. According to the double-station die changing trolley, through the double stations arranged on the die changing trolley, the working efficiency of the die changing trolley is improved; and the driving mechanism in the push-pull mechanism is arranged inside the die changing trolley, so that the die changing trolley structure is small in occupied area, workers can operate the die changing trolley conveniently, and the die changing efficiency is improved by adopting the dual-power die changing mechanism.

Owner:江苏格莱富智能装备有限公司

Mold frame system capable of quickly replacing mold core

The invention provides a mold frame system capable of quickly replacing a mold core, and relates to the technical field of molds. The mold frame system capable of quickly replacing the mold core solves the technical problem of low efficiency caused by the fact that the mold core can be replaced only when the mold is disassembled from an injection molding machine during wire changing production inthe prior art. The mold frame system capable of quickly replacing the mold core comprises a front mold frame, a rear mold frame, a front mold core and a rear mold core, wherein mold core mounting grooves are formed in the front mold frame and the rear mold frame, the front mold core and the rear mold core are correspondingly arranged in the mold core mounting grooves of the front mold frame and the rear mold frame, threaded holes are formed in the back surfaces, opposite to a mold clamping surface, of the front mold core and the rear mold core, bolts can correspondingly penetrate through the mold core mounting grooves of the front mold frame and the rear mold frame and can be correspondingly connected with corresponding threaded holes in a threaded way, and the front mold core, and the rear mold core and the rear mold frame can be matched with the threaded holes through bolts. According to the mold frame system capable of quickly replacing a mold core, the mold replacing efficiency isvery high and rapid line changing production is realized.

Owner:中山英诺莱比智能科技有限公司

Injection mould capable of being easily de-molded

The invention discloses an injection mould capable of being easily de-molded. The injection mould is formed by a movable mould and a fixed mould, which are used as the injection mould, wherein each one of the movable mould and the fixed mould comprises a molding part, a pushing-out mechanism, a mould guide part and a pouring system; a mould cavity is arranged in the mould; the mould cavity is arranged on the mould closing face of the single injection mould, namely, the mould cavity is arranged on the mould closing face of the movable mould or the mould closing face of the fixed mould; the mould closing face of the other injection mould has no mould cavity and is a plane; the movable mould and the fixed mould are closed to form the complete injection mould cavity. According to the injection mould disclosed by the invention, the structure of only arranging the mould cavity on the single injection mould is applicable to injection of a standard test sample strip or an injection piece with the similar shape. The injection mould has the beneficial effects of being beneficial to simplification of the structure of the mould, improving the manufacturability of the mould and reducing the cost of the mould.

Owner:广州现代塑料有限公司

Die changing trolley with lifting and quick positioning functions

Owner:JIANGSU ZHISHI TECH CO LTD

Quick mold changing device, injection molding machine, and quick mold changing method for injection molding machine

Owner:GREE ELECTRIC APPLIANCES INC

Drawing die

The invention discloses a drawing die which comprises an upper die base, a lower die base and a blank holder. The blank holder area of the blank holder is provided with a special-shaped blank holder face. The blank holder face comprises a plurality of convex parts and a plurality of concave parts. The convex parts and the concave parts are in alternative distribution, and the adjacent convex parts and concave parts are connected. The opening width of each convex part is equal to the opening width of the corresponding concave part. The largest depth of each convex part is equal to the largest depth of the corresponding concave part. The convex parts and the concave parts form the wave-shaped blank holder face, wastes after drawing can be shrunk by the wave-shaped blank holder face, the appearance quality of car cover parts is guaranteed, the waste area after drawing and shrinking is reduced, and the waste discharge problem in a trimming process is solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

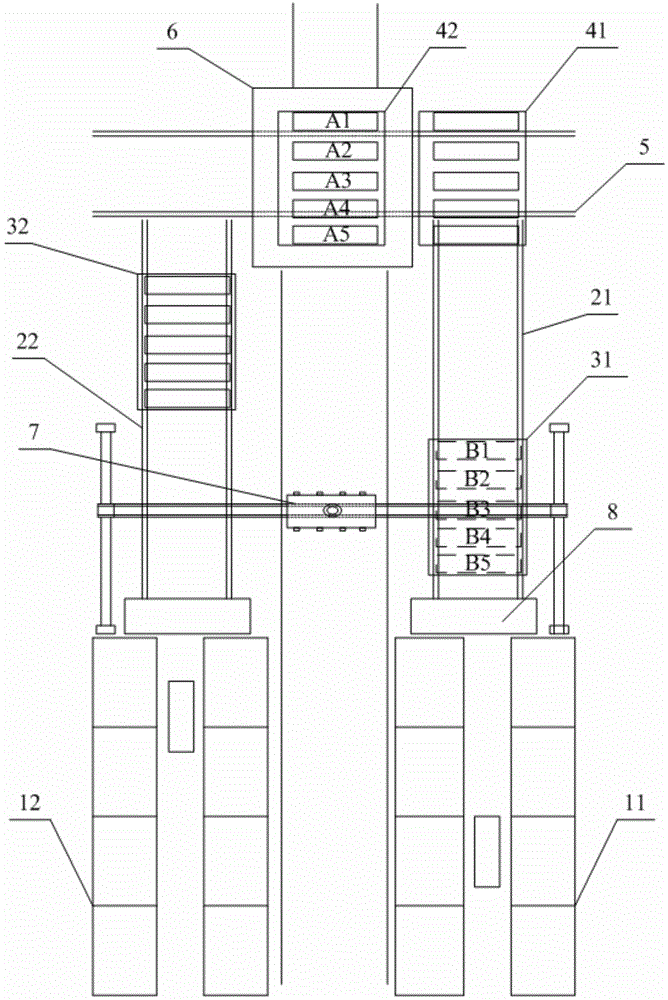

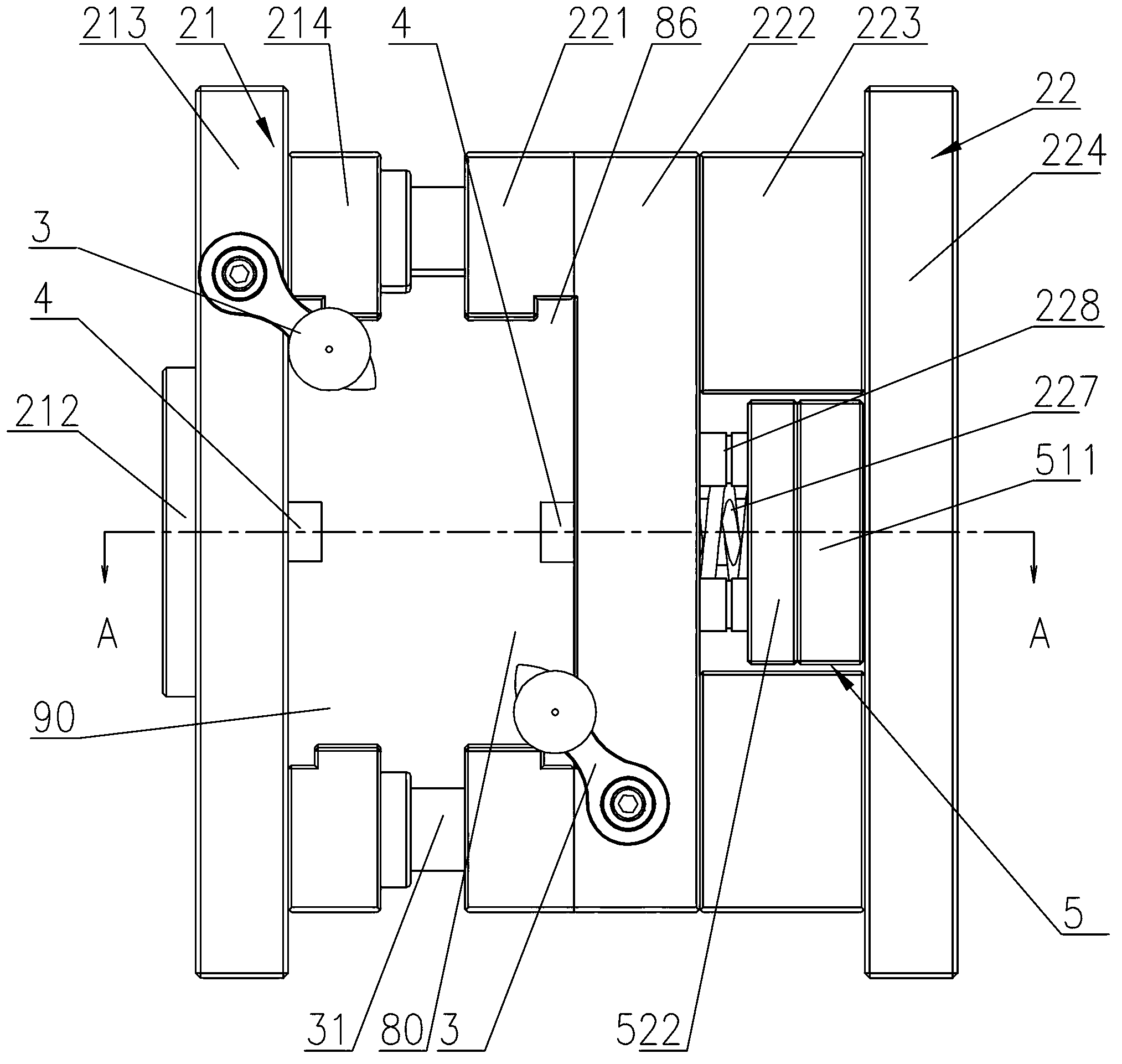

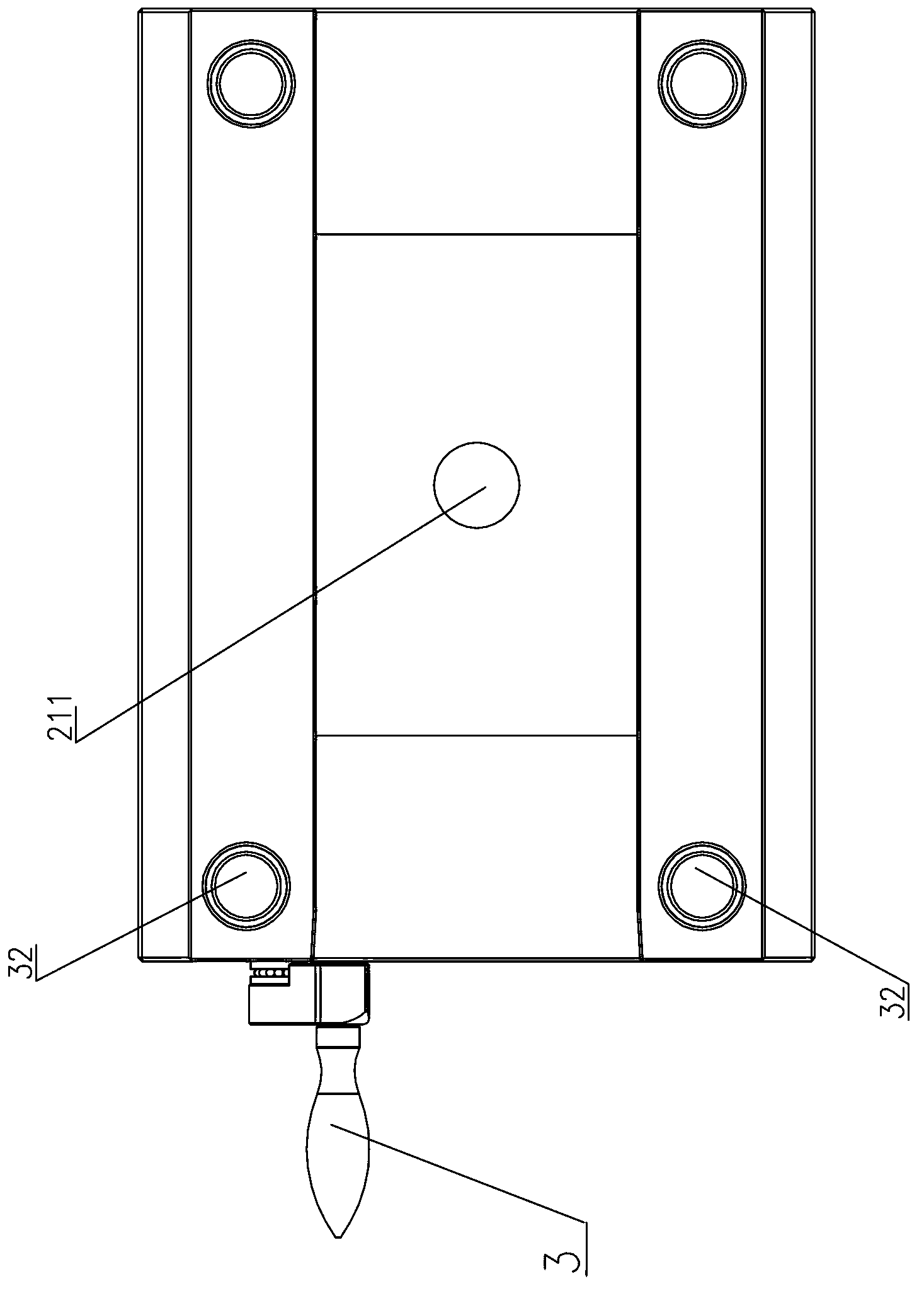

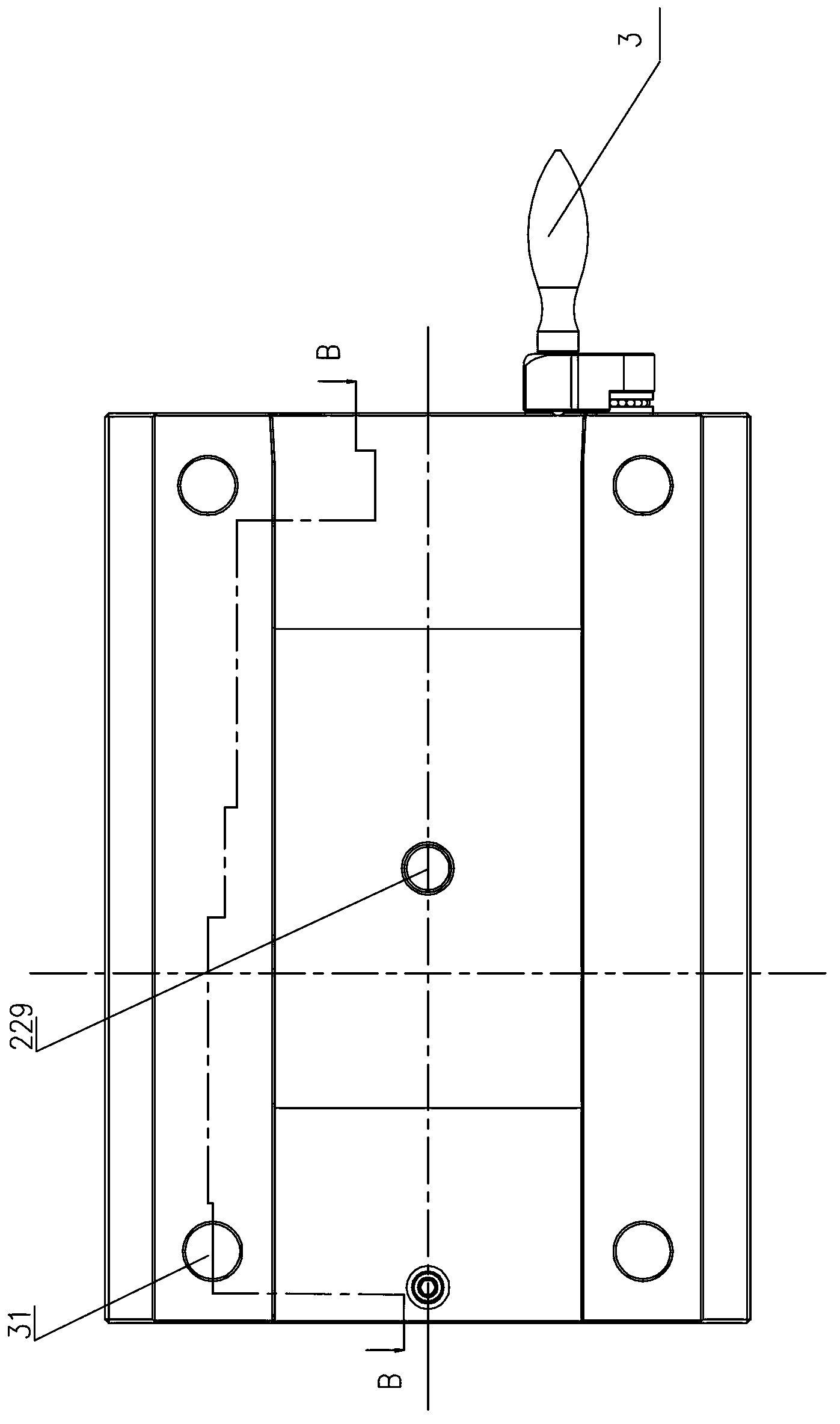

Stamping die changing system and method

The invention provides a stamping die change system which is used for changing a die for a press and comprises a die library and a trolley moving rail, wherein the die library is used for storing the die and is connected with the press through the trolley moving rail. A die change trolley for conveying the die is arranged on the trolley moving rail, a die arrangement device for carrying the die is arranged between the die library and the trolley moving rail, a worktable is arranged on the press and in butt joint with the trolley moving rail to place the die, and a worktable conveying rail for conveying the worktable to the working position of the press is arranged on the press. The die is conveyed out of the die library, conveyed to the worktable of the press by the die change trolley, conveyed to the preset working position of the press by the worktable and stamped. The die is stored by the die library, conveyed by the die change trolley, automatically conveyed in placed by the worktable of the press and rapidly and accurately changed, and die change efficiency is improved. The invention further provides a stamping die change method.

Owner:GREE ELECTRIC APPLIANCES INC

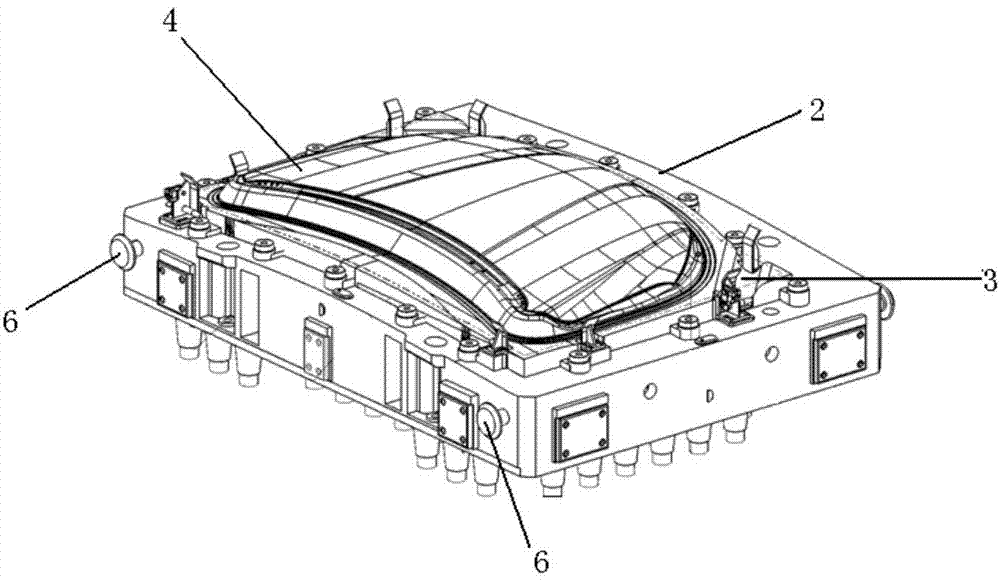

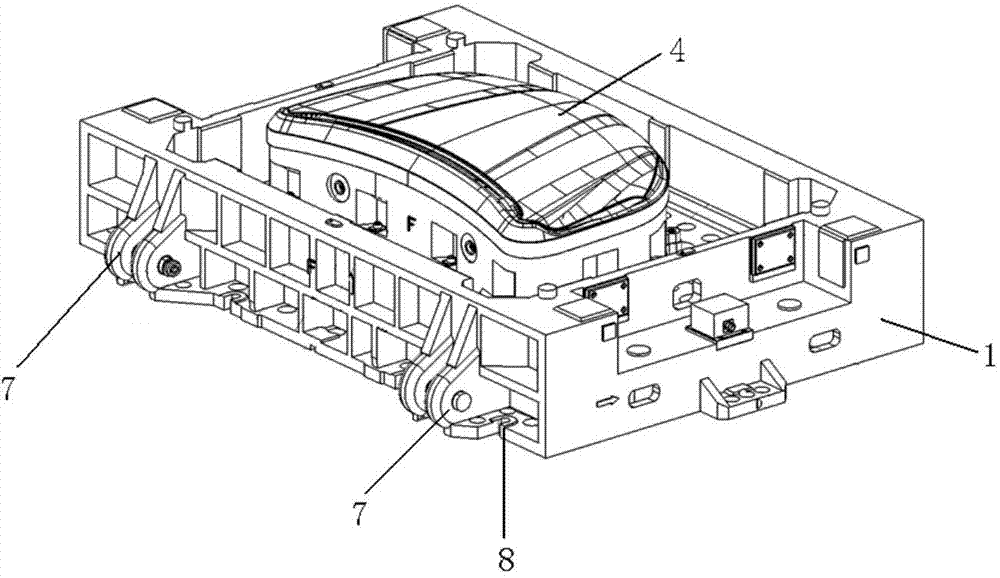

Novel fixture mechanism for refrigerator door body foaming line

PendingCN110450330AReduce labor intensityImprove mold change efficiencyDomestic articlesEngineeringRefrigerated temperature

Owner:CHANGHONG MEILING CO LTD

Stamping die for automobile part machining

PendingCN114273524AImprove mold change efficiencyImprove work efficiencyShaping toolsEjection devicesMotor vehicle partTransmission belt

The invention discloses a stamping die for automobile part machining, and relates to the technical field of die stamping, the stamping die comprises a bottom plate and further comprises supporting rods arranged on the two sides of the bottom plate, and the tops of the supporting rods are fixedly connected with a top plate; the switching mechanism is arranged between the supporting rods and comprises a mounting rod, the mounting rod is fixedly connected with the bottom plate, one side of the mounting rod is rotatably connected with a switching disc, the side wall of the mounting rod on one axial side of a rotating shaft of the switching disc is rotatably connected with a mounting wheel, one axial side of the rotating shaft of the mounting wheel is fixedly connected with the rotating shaft of the switching disc, and the switching disc is fixedly connected with a suction cup. A mold plate is fixedly adsorbed on the suckers, the side walls of the mounting rods are fixedly connected with positioning rods, one sides of the positioning rods are rotationally connected with rotating wheels, a transmission belt is arranged between the rotating wheels and the mounting wheels, a telescopic assembly is arranged on the transmission belt, and the feeding mechanism is arranged between the mounting rods and used for feeding and discharging. The driving mechanism is arranged above the top plate and used for driving the telescopic assembly below to conduct stamping.

Owner:上海乾驰模具有限公司

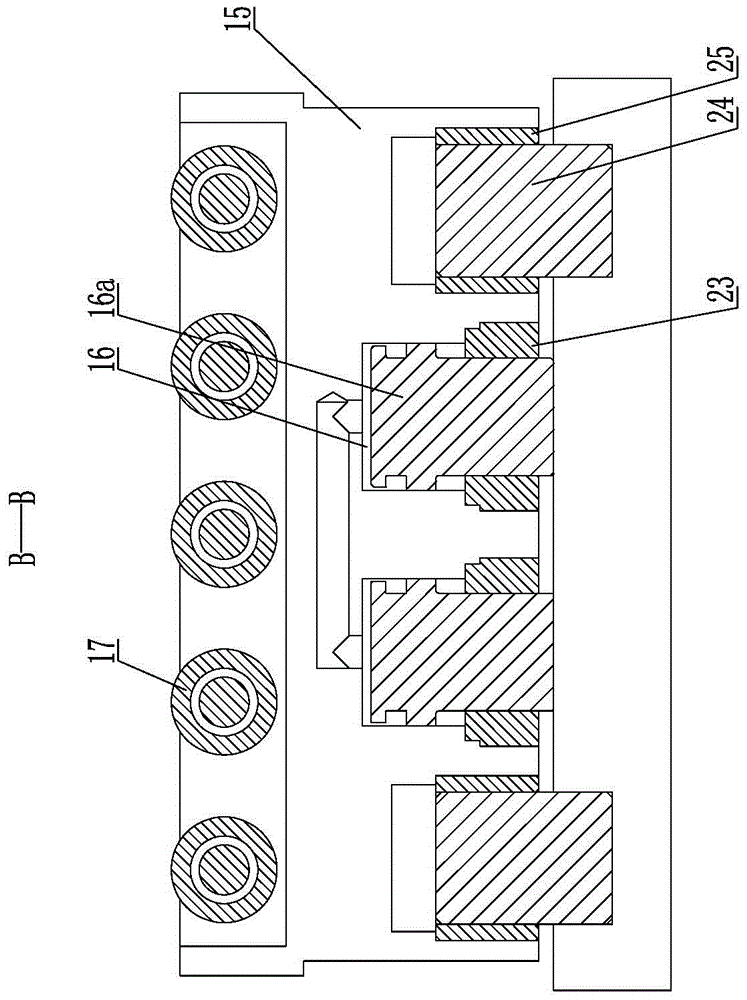

Double-station bidirectional die changing trolley

ActiveCN112338069AImprove mold change efficiencyShaping toolsElectrical and Electronics engineeringMechanical engineering

The invention relates to a double-station bidirectional die changing trolley. The double-station bidirectional die changing trolley comprises a trolley body, four lifting type push-pull die changing machines and four auxiliary guide rails, wherein the four auxiliary guide rails are arranged on the trolley body in parallel at intervals, the two ends of the auxiliary guide rails extend out of the trolley body, every two auxiliary guide rails form a set, every two lifting type push-pull die changing machines are arranged between every two sets of guide rails, and the two lifting type push-pull die changing machines face the two ends of the auxiliary guide rails correspondingly. Compared with the prior art, the double-station bidirectional die changing trolley is provided with the four liftingtype push-pull die changing machines, the two lifting type push-pull die changing machines face one side of the double-station bidirectional die changing trolley, the two lifting type push-pull die changing machines face the other side of the double-station bidirectional die changing trolley, dies can be changed for equipment located on the two sides of the double-station bidirectional die changing trolley at the same time, and the existing die changing efficiency can be doubled.

Owner:武汉博莱恩智能装备有限公司

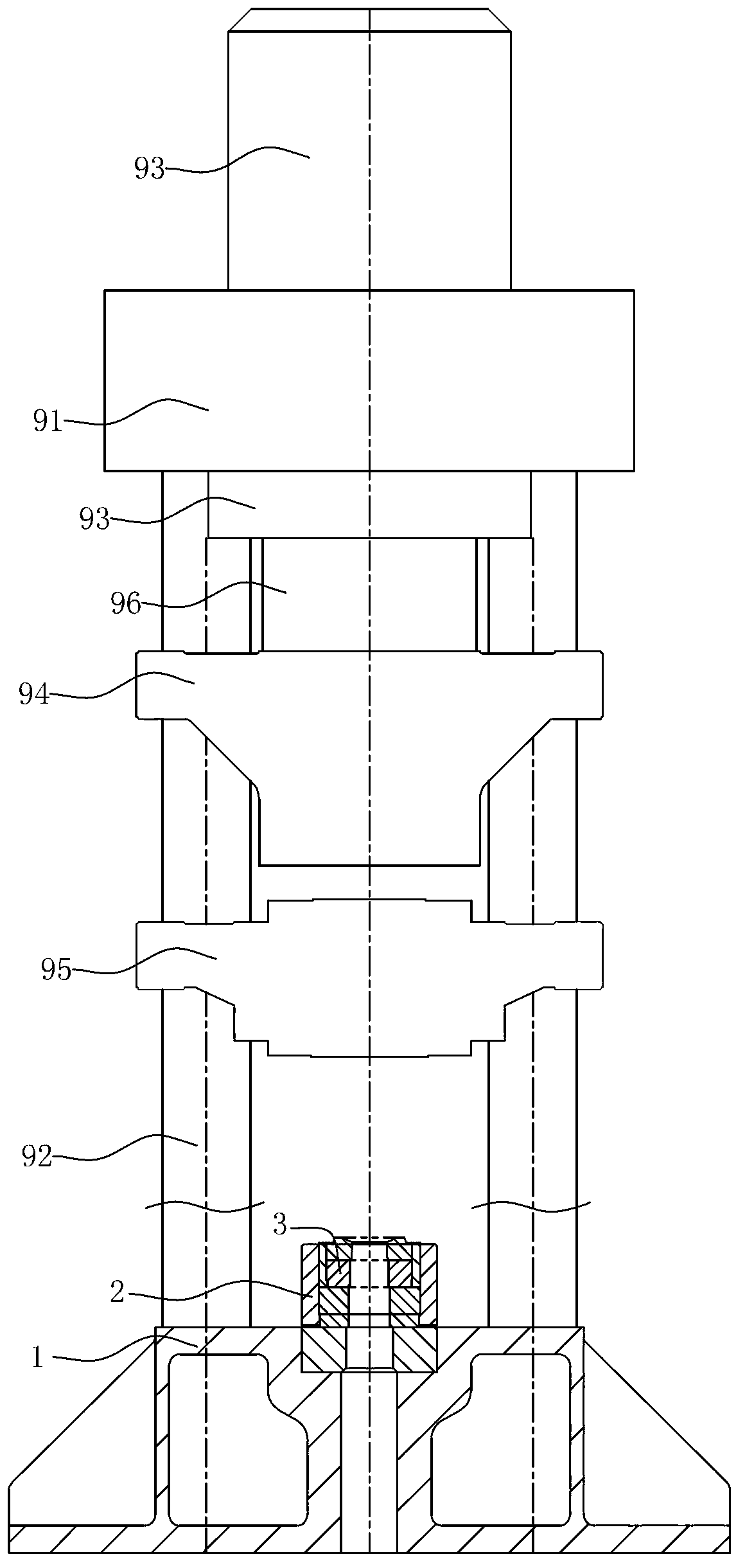

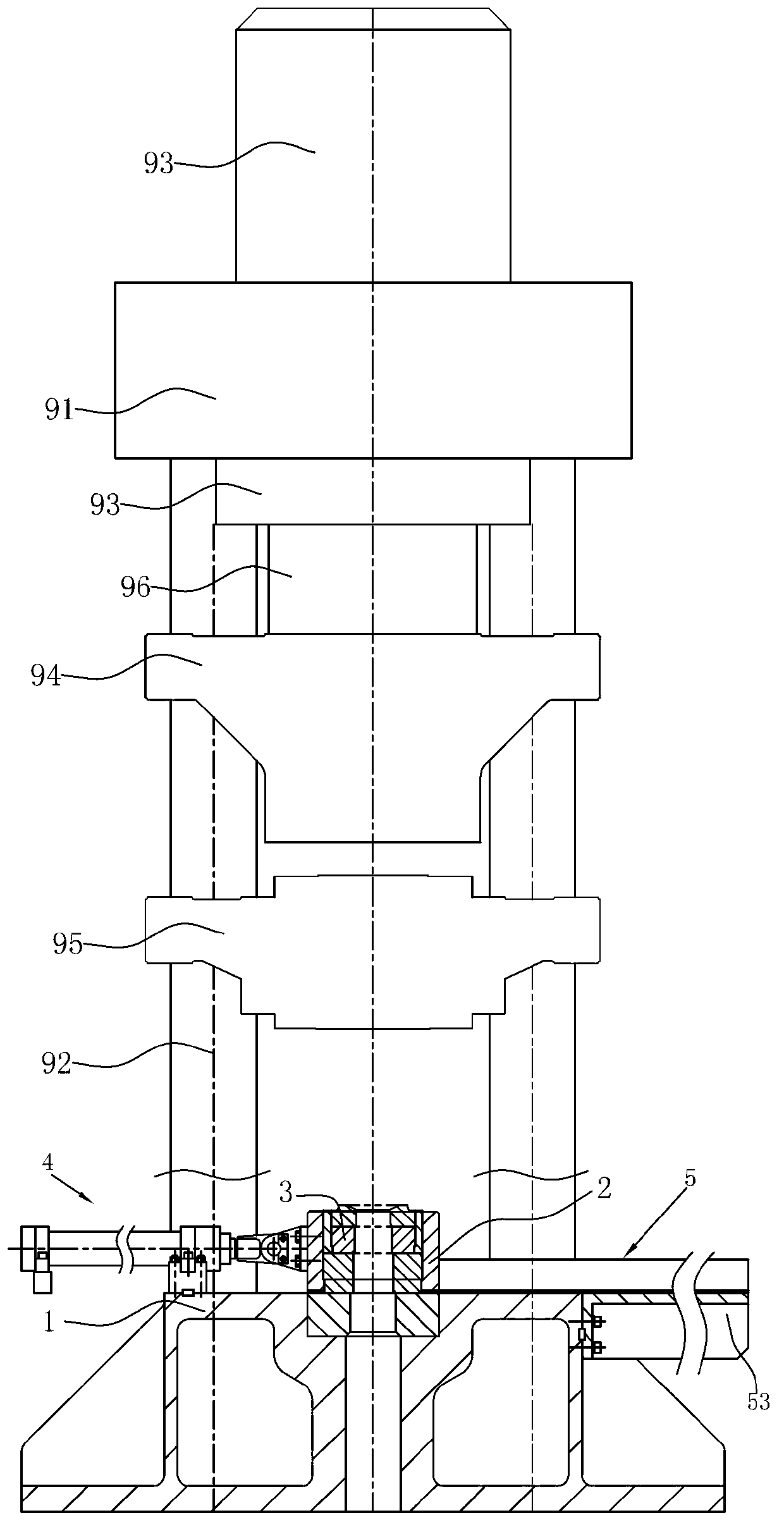

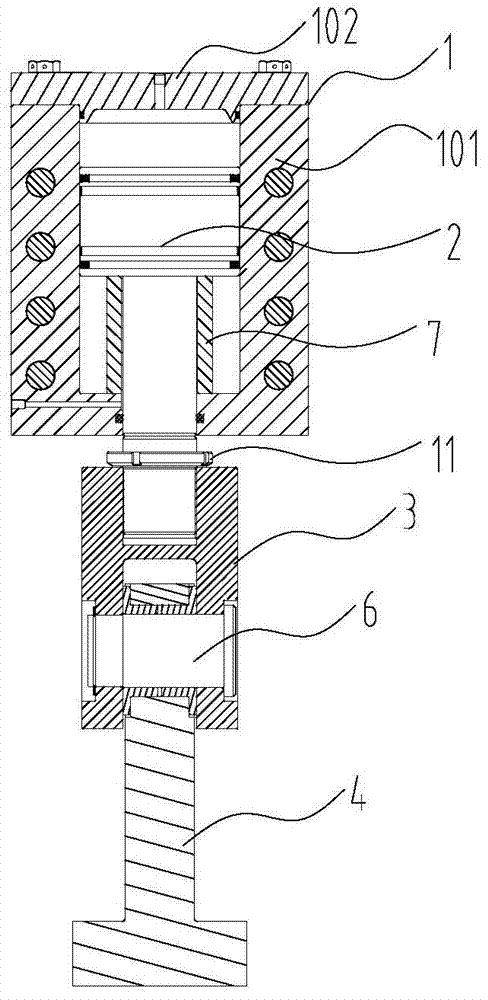

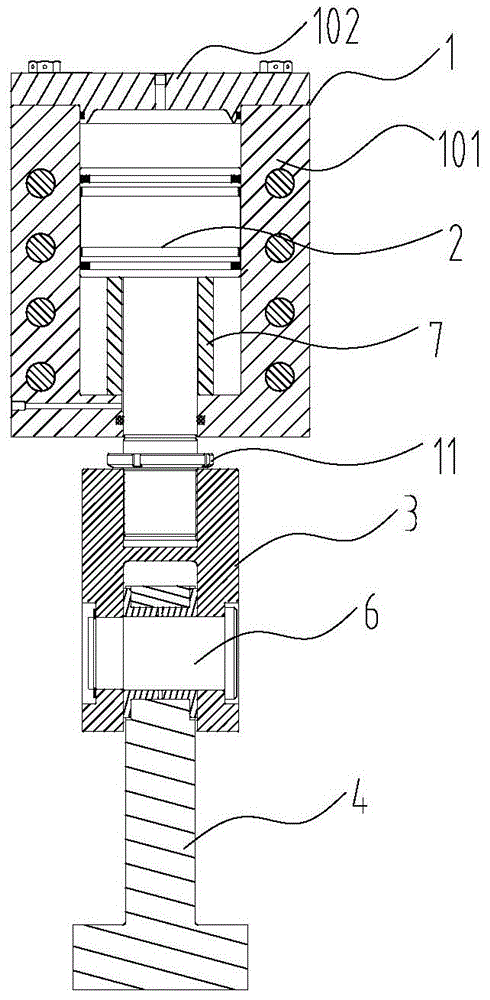

Clamping device of upper die base of hot die forging press

ActiveCN104493046ASimple structureEasy to operateForging/hammering/pressing machinesInverted-T shapeEngineering

The invention discloses a clamping device of an upper die base of a hot die forging press and belongs to the field of forging and pressing equipment. The clamping device comprises a bearing body, a piston, an intermediate connecting body, a swinging block, a swinging block driving mechanism and a piston driving mechanism. The bearing body is provided with an enclosed cavity, the piston is arranged in the enclosed cavity and divides the enclosed cavity into an upper cavity and a lower cavity, a piston rod connected with the piston penetrates the bottom wall of the bearing body, and the piston driving mechanism drives the piston to move in the enclosed cavity. One end of the swinging block is a connecting end while the other end is a free end, one end of the intermediate connecting rod is connected with the piston rod while the other end is hinged to the connecting rod of the swinging block through a connecting pin, and the free end of the swinging block is inverted-T shaped. The swinging block driving mechanism drives the swinging block to swing around the connecting pin. The clamping device has the advantages of simple structure, convenience in operation, high die change efficiency, low manufacture and maintenance cost and the like, production efficiency is improved, and production cost is lowered.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

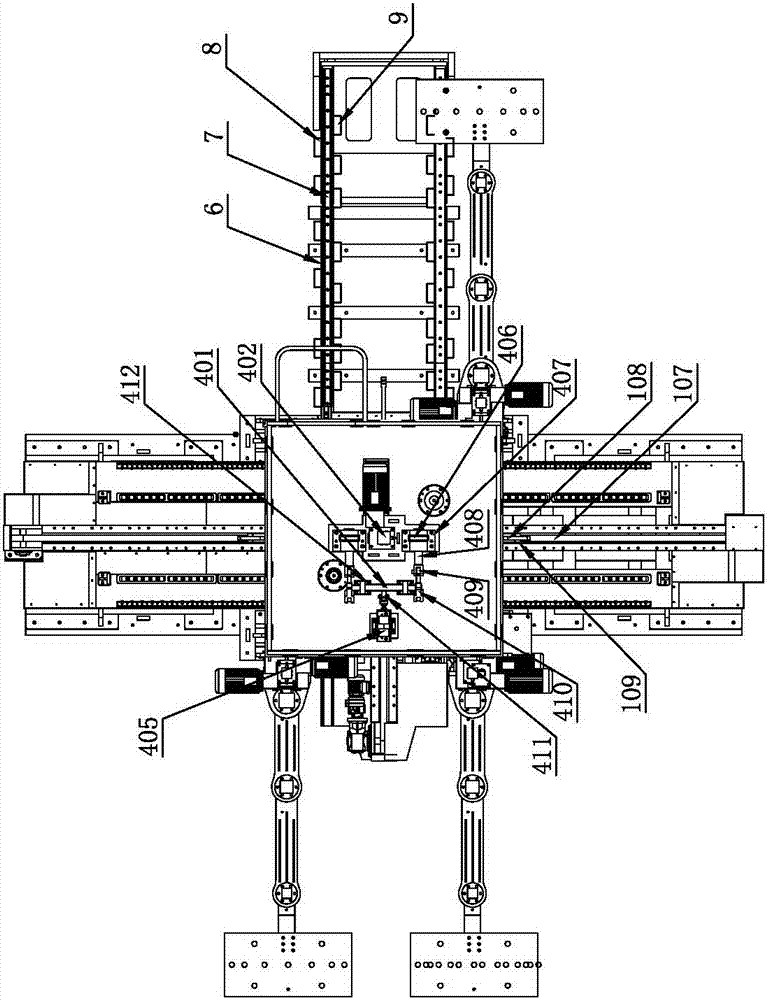

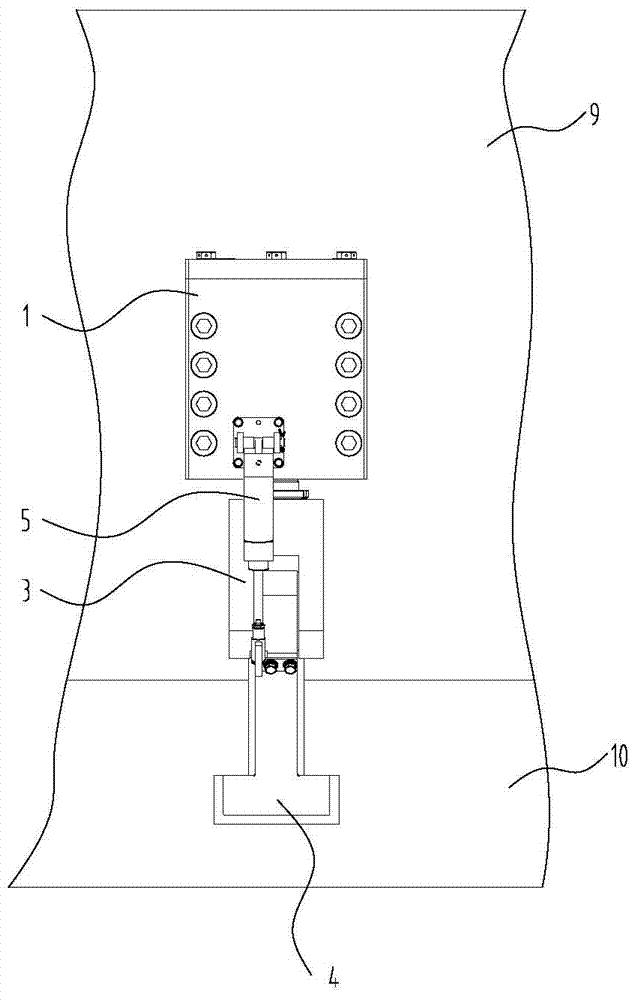

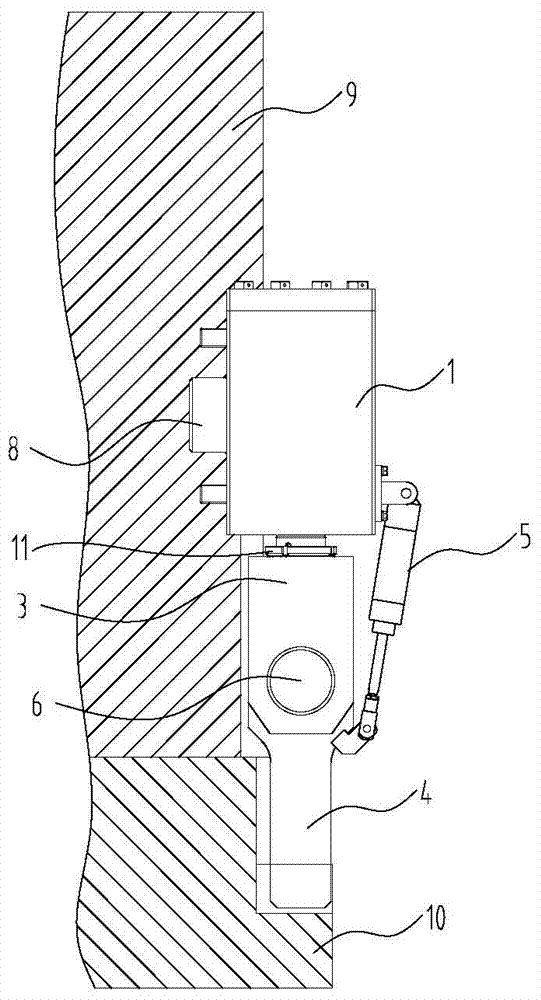

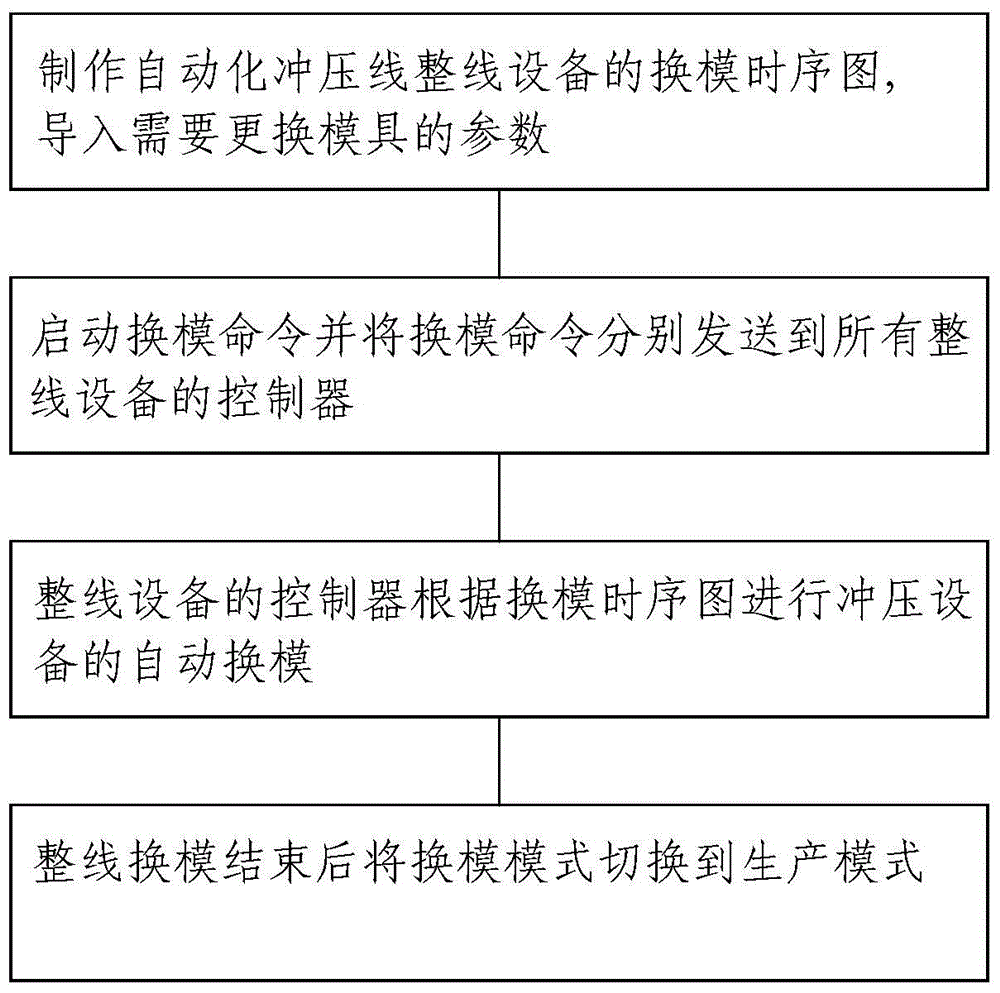

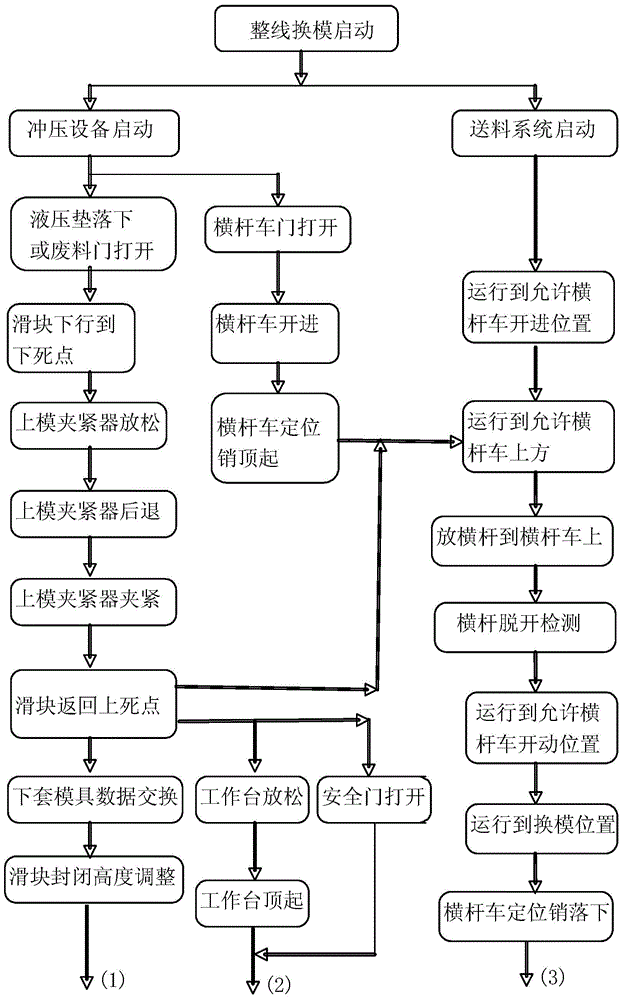

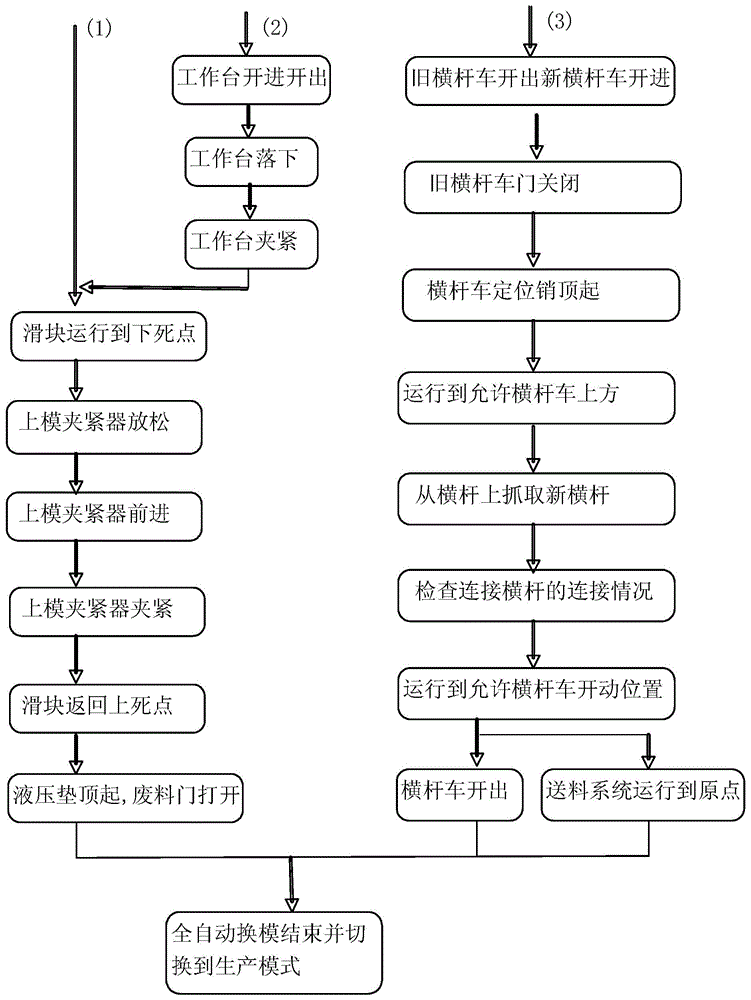

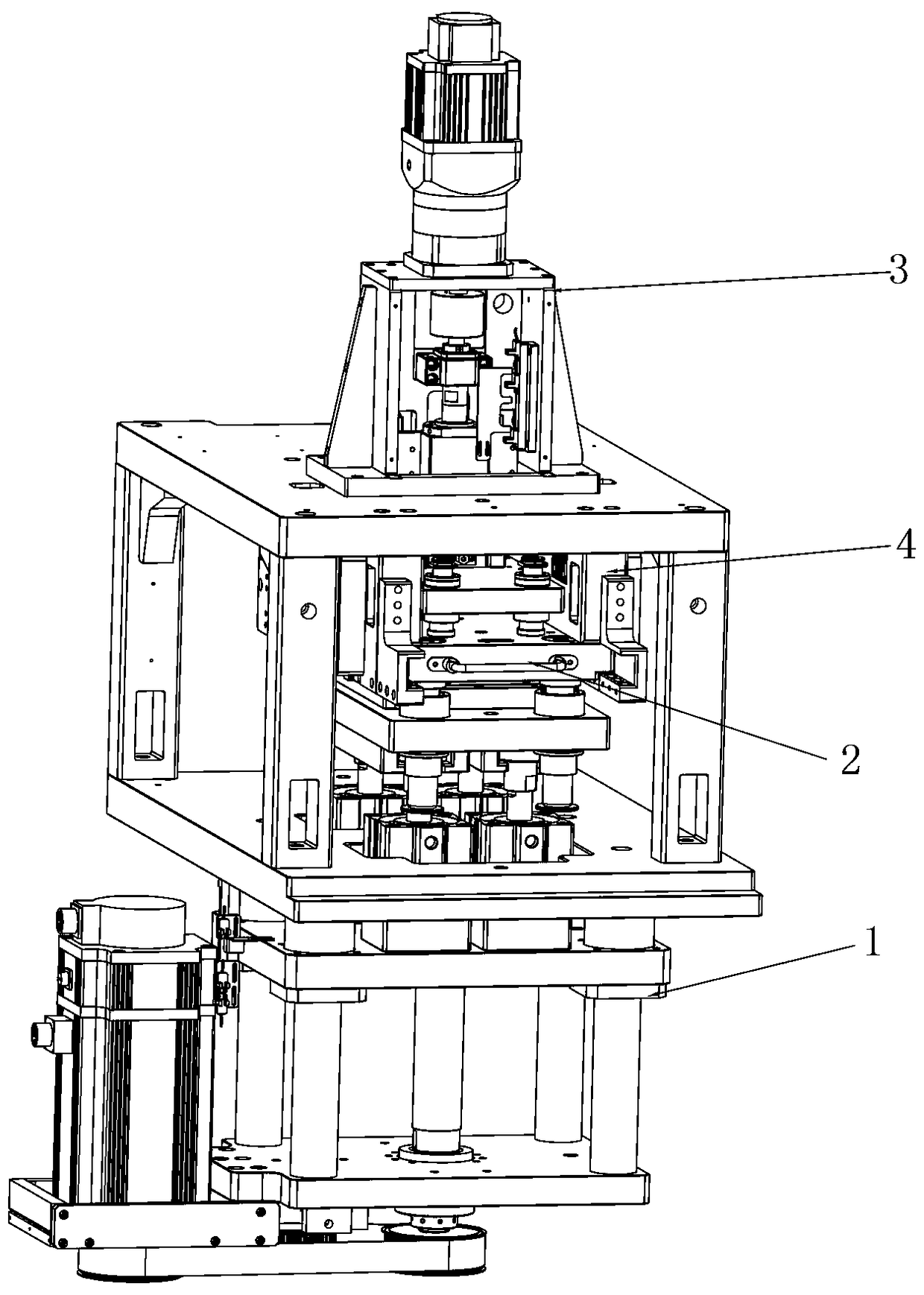

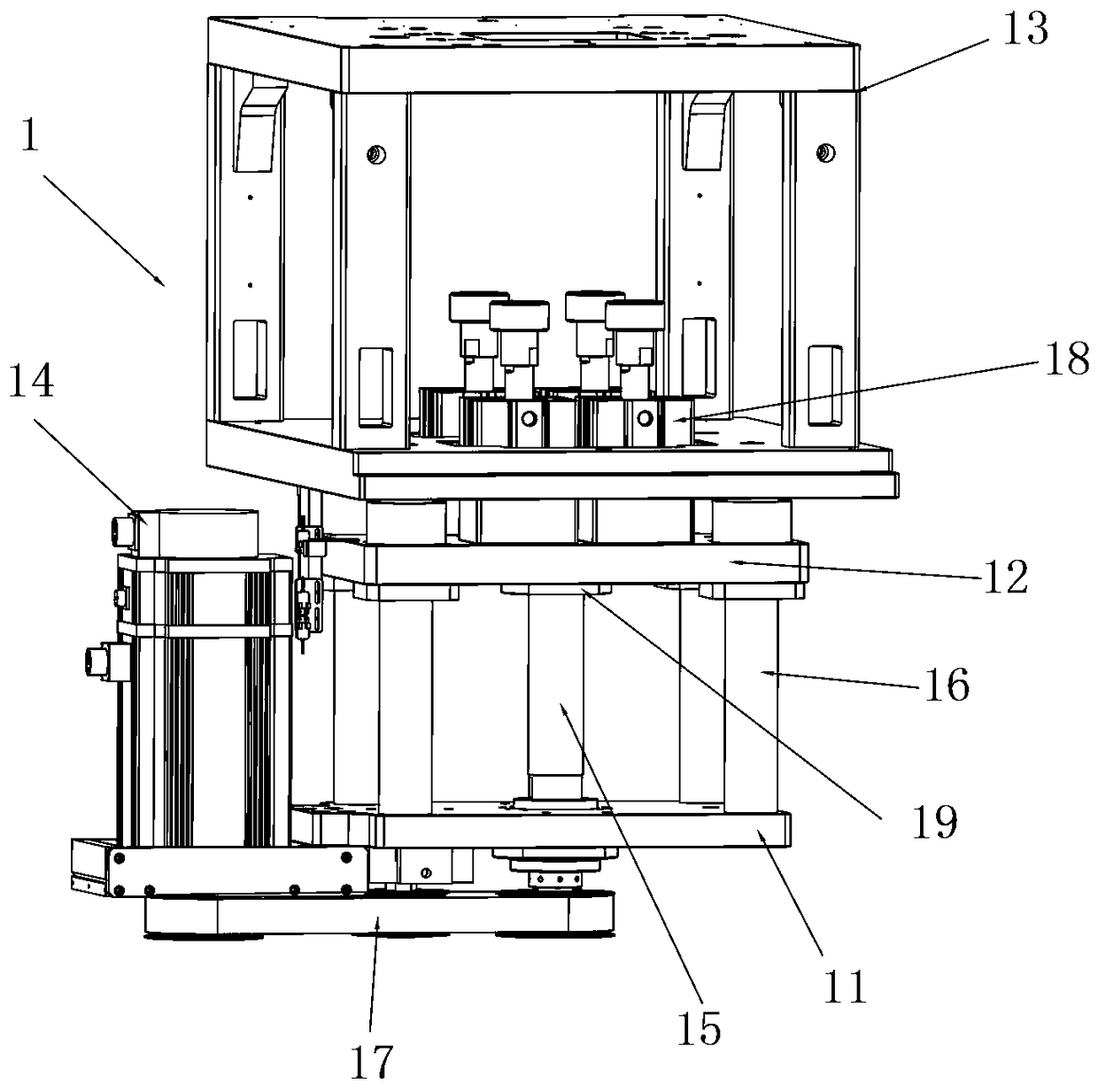

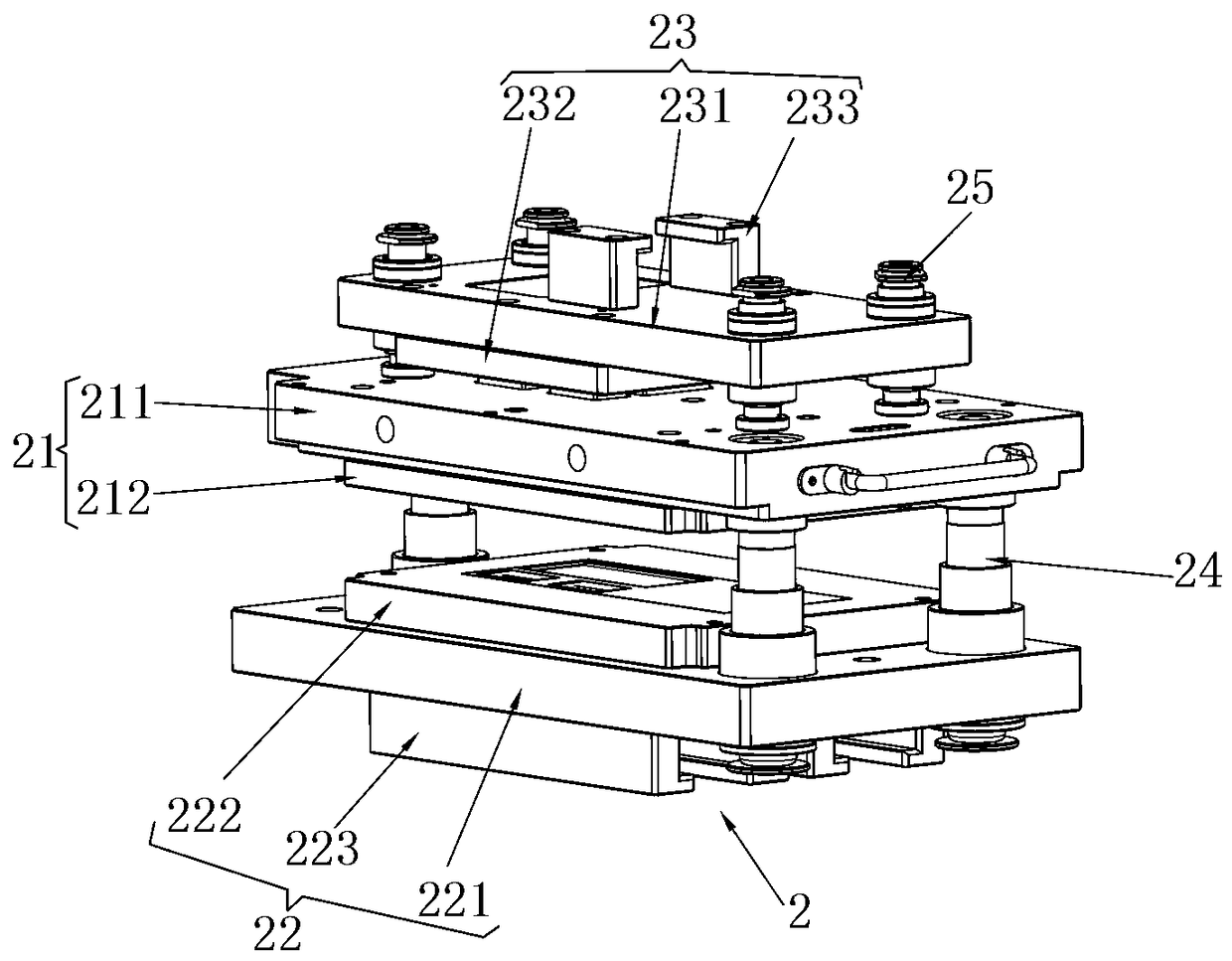

Automatic Die Changing Method for Stamping Equipment of Automatic Stamping Line

The invention provides an automatic mold replacing method for automated punch-line punching equipment. The method comprises the following steps: making a mold replacing time sequence diagram for automated punch-line equipment in a whole production line, and inputting parameters of a mold which needs to be replaced; starting a mold replacing order, and sending the mold replacing order to the controllers of all equipment in the whole production line respectively; performing automatic mold replacement on the punching equipment according to the mold replacing time sequence diagram by the controllers of the equipment in the whole production line; converting the mold replacing mode into the production mode when finishing the mold replacement in the whole production line. In the method provided by the invention, mold replacement is performed according to the mold replacing time sequence diagram, and the mold replacing procedure is memorized, and the problems that automatic-line manual mold replacement consumes a long time and is large in safety risk is solved, so that not only is the mold replacing period greatly shortened, the mold replacing efficiency improved, the safety of equipment and stuff guaranteed, but also the automation level and the production efficiency of the whole production line are improved, and the safety performance of the equipment is improved.

Owner:JIER MACHINE TOOL GROUP

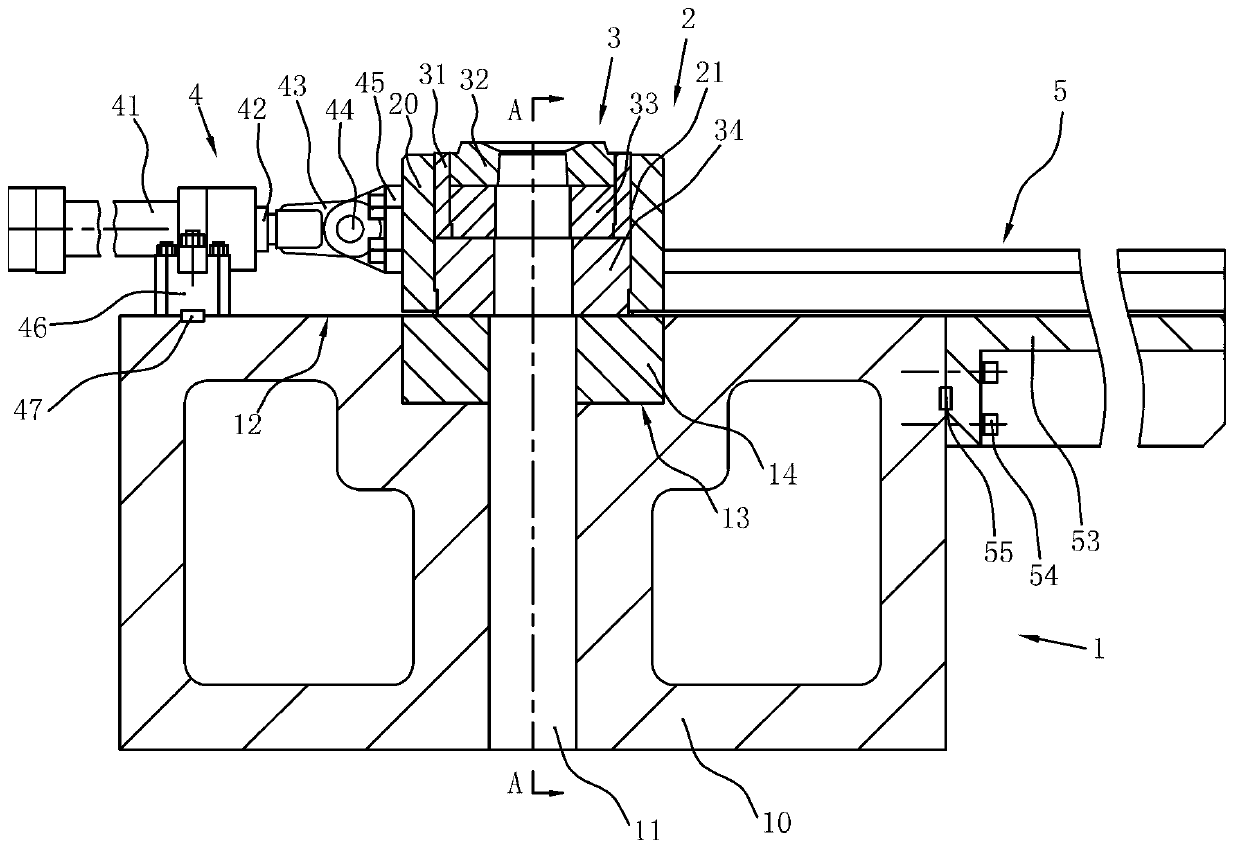

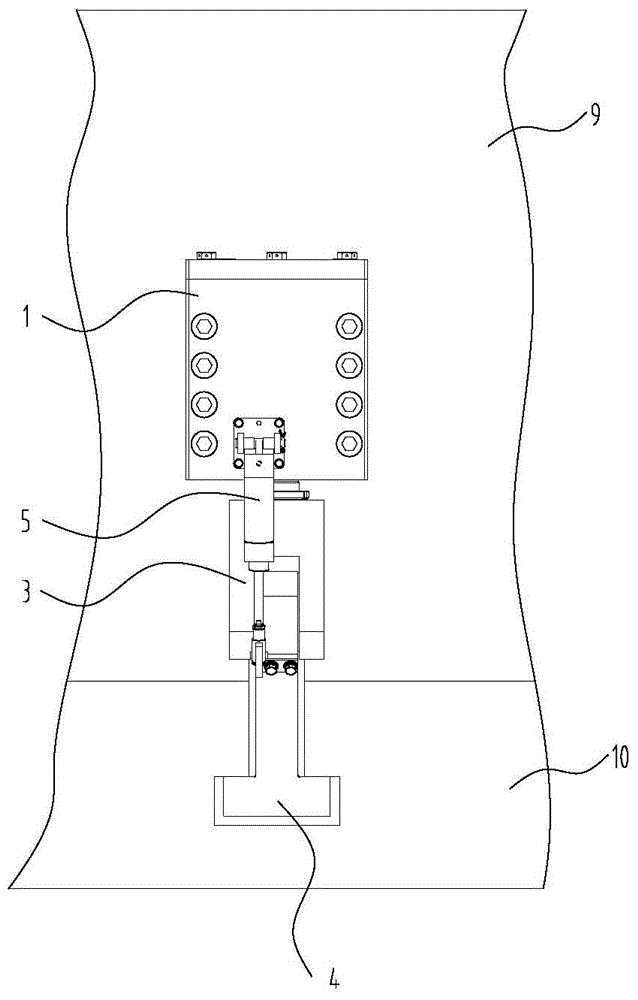

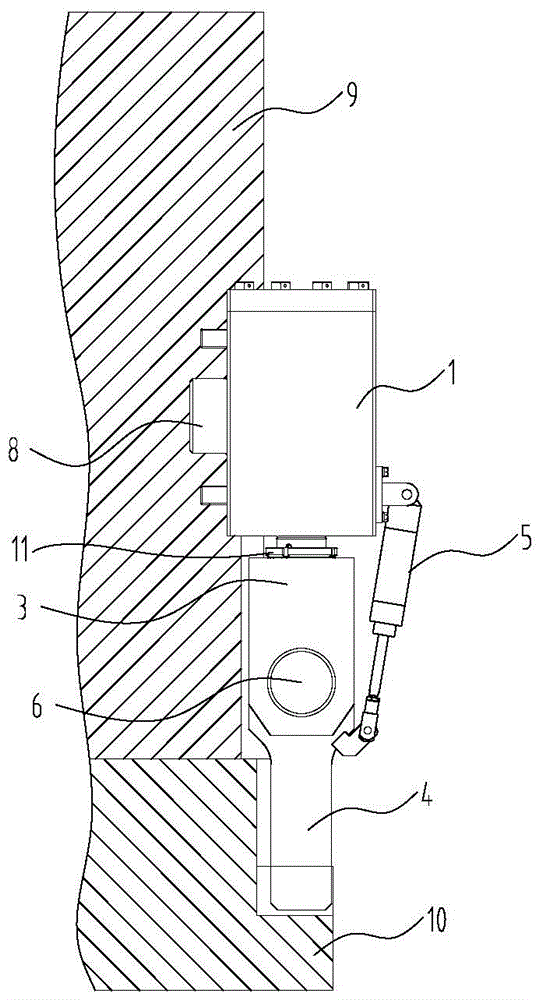

Pit punching mechanism for lithium battery packaging equipment

PendingCN109326830AQuick changeoverHigh positioning accuracyFinal product manufactureElectrolyte accumulators manufacturePunchingEngineering

The invention discloses a pit punching mechanism for lithium battery packaging equipment. The pit punching mechanism comprises a jacking device, a pit punching mould device, a pit punching driving device and a pit punching mould fixing seat, wherein the pit punching mould device comprises an upper mould assembly, a lower mould assembly and a punching head assembly; the lower mould assembly is fixed to the lower end of the upper mould assembly through a first guiding assembly, the lower end of the lower mould assembly is connected with the jacking device, the punching head assembly is fixed tothe upper end of the upper mould assembly through a second guiding assembly, the upper end of the punching head assembly is connected with the pit punching driving device, and the upper mould assemblyis arranged on the pit punching mould fixing seat and can slide. According to the pit punching mechanism disclosed by the invention, when a mould is replaced, the mould can integrally slide to the pit punching mould fixing seat; thus, the whole pit punching mould device can be suspended and fixed on the pit punching mould fixing seat, quick mould replacement is achieved, the location accuracy ishigh, the mould replacement efficiency is greatly improved, and the maintenance cost is saved.

Owner:东莞哈工自控科技有限公司

Injection molding machine mold replacing and stripping device

InactiveCN111645262AImprove mold change efficiencyIncrease productivityInjection molding machineMechanical engineering

The invention discloses an injection molding machine mold replacing and stripping device. The injection molding machine mold replacing and stripping device comprises a base; supporting blocks are symmetrically arranged at the left end and the right end of the base, a top plate is fixedly installed at the upper ends of the supporting blocks, a mold replacing cavity is formed in the front portion ofthe base, and a connecting cavity is formed in the rear side of the mold replacing cavity; and a mold replacing assembly used for replacing a mold is arranged above the base and comprises a left moldblock fixedly installed on the left portion of the upper end of the base. When the device works, a mold replacing plate can replace a mold through the mold replacing assembly, injection molding products can be demolded through a demolding assembly, the products can enter a collecting box through suction cups by means of a product collecting assembly, the mold replacing efficiency is improved, thepersonal safety is guaranteed, and the production efficiency is improved.

Owner:HANGZHOU YABANG INTELLIGENT TECH CO LTD

Pipe end machine convenient for die changing

PendingCN111375677ATime-consuming and laborious to solveEasy stampingShaping toolsGear wheelPipe fitting

The invention discloses a pipe end machine convenient for die changing. The pipe end machine comprises a controller, a rack, a punch device, a driving assembly used for driving the punch device to push forwards, and a positioning device used for clamping a pipe. The punch device comprises a movable mounting plate and a plurality of stamping heads elastically installed on the mounting plate. The mounting plate is slidably connected to the rack, and the sliding direction of the mounting plate is perpendicular to the stamping direction of the stamping heads. The positioning device is arranged atthe front end of the stamping direction of the stamping heads. The driving assembly drives the stamping heads to move to the positioning device. According to the pipe end machine, different stamping heads are arranged on the mounting plate, and when the stamping heads need to be replaced, the stamping heads can be replaced just by moving the mounting plate through a gear rack device; the end of the clamped pipe on the positioning device is stamped and shaped by using the stamping heads so as to solve the problems of time waste and labor waste during die changing; and the die changing efficiency is effectively improved, and stamping of different pipe end shapes is facilitated.

Owner:广东弘毅智能装备有限公司

Die changing trolley and die changing method thereof

PendingCN114248340AAchieve storageAchieve replacementMouldsMould auxillary partsStructural engineeringMechanical engineering

The invention relates to a die changing trolley and a die changing method thereof, the die changing trolley comprises a driving mechanism, a lifting mechanism mounted on the driving mechanism and a die changing mechanism driven by the lifting mechanism to lift, a mounting support is further fixedly arranged on the side, close to the die changing end, of the driving mechanism, and a rail connecting mechanism is mounted at the upper end of the mounting support; the die changing mechanism comprises at least two layers of die changing components which are arranged in parallel through a support. According to the die changing trolley combined with the die changing method, die core changing can be achieved through single equipment, the changing time is shortened, and the changing efficiency is improved.

Owner:JIANGXI HEMEI CERAMICS +1

The Clamping Device of the Upper Die Holder of the Hot Die Forging Press

ActiveCN104493046BSimple structureEasy to operateForging/hammering/pressing machinesInverted-T shapeEngineering

The invention discloses a clamping device of an upper die base of a hot die forging press and belongs to the field of forging and pressing equipment. The clamping device comprises a bearing body, a piston, an intermediate connecting body, a swinging block, a swinging block driving mechanism and a piston driving mechanism. The bearing body is provided with an enclosed cavity, the piston is arranged in the enclosed cavity and divides the enclosed cavity into an upper cavity and a lower cavity, a piston rod connected with the piston penetrates the bottom wall of the bearing body, and the piston driving mechanism drives the piston to move in the enclosed cavity. One end of the swinging block is a connecting end while the other end is a free end, one end of the intermediate connecting rod is connected with the piston rod while the other end is hinged to the connecting rod of the swinging block through a connecting pin, and the free end of the swinging block is inverted-T shaped. The swinging block driving mechanism drives the swinging block to swing around the connecting pin. The clamping device has the advantages of simple structure, convenience in operation, high die change efficiency, low manufacture and maintenance cost and the like, production efficiency is improved, and production cost is lowered.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Die changing device

InactiveCN107053007AImprove mold change efficiencyImprove securityGrinding feedersGrinding/polishing safety devicesEngineeringMechanical engineering

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com