Automatic die rotating and replacing device for bending machine

A bending machine and automatic technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large handling space span, non-circular mold, large space occupation, etc., to improve space utilization and mold change efficiency The effect of improving and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

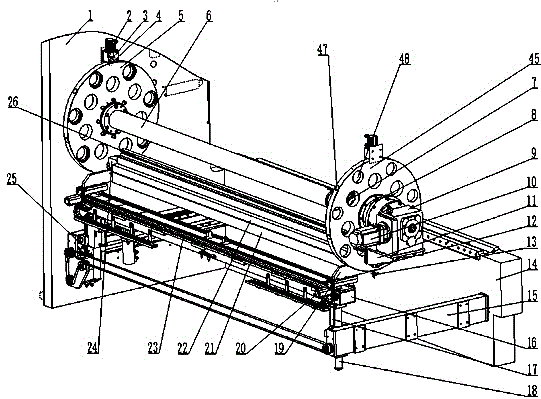

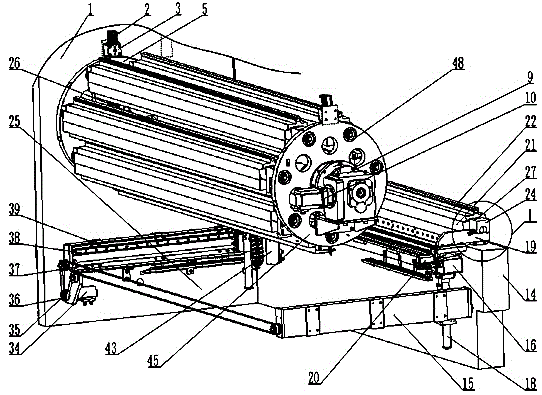

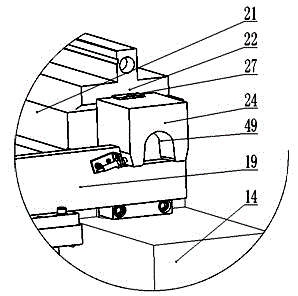

[0033] Such as figure 1 As shown, the automatic rotary mold conversion device of the bending machine includes a mold turnover mechanism 26 and a mold backstop and handling mechanism 25 arranged between the left and right vertical plates 1 on the bed, such as Figure 4 As shown, the mold turnover mechanism 26 includes: a left bearing seat 31 and a right bearing seat 8 which are respectively fixedly arranged on the vertical plates 1 on the left and right sides, and a left turntable shaft 30 is installed through a bearing on the left bearing seat 31, and when turning left On the disc shaft 30, the left rotary wheel disc 5 pivoting with the left rotary disc shaft 30 is fixedly arranged; The right rotary wheel 45 pivoted by the shaft 32; the left rotary wheel 5 and the right rotary wheel 45 are connected together through a rigid connection shaft 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com