Double-station bidirectional die changing trolley

A double-station, mold trolley technology, applied in the field of mold changing vehicles, can solve the problem of changing molds for a piece of equipment, and achieve the effect of improving mold changing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

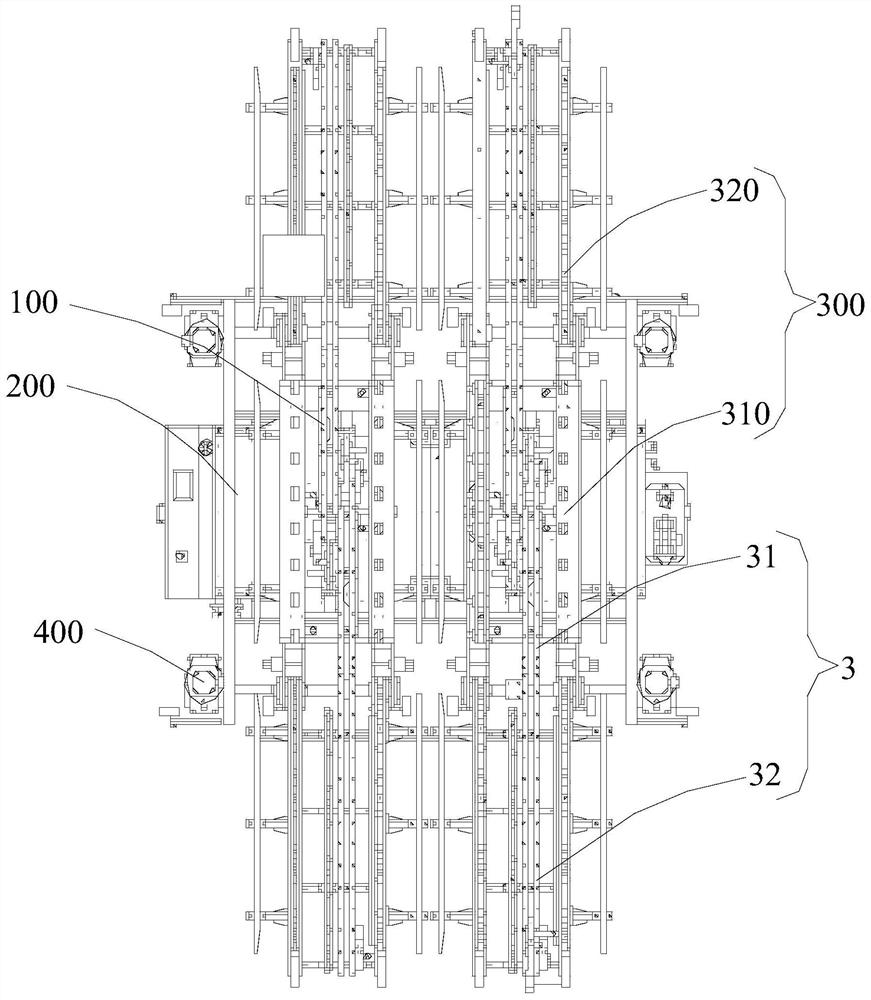

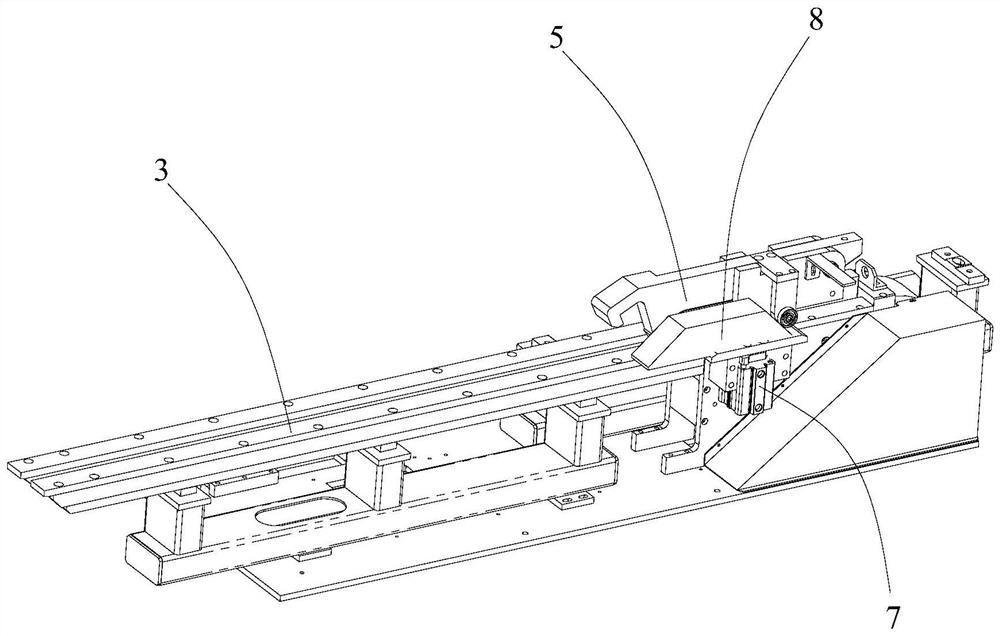

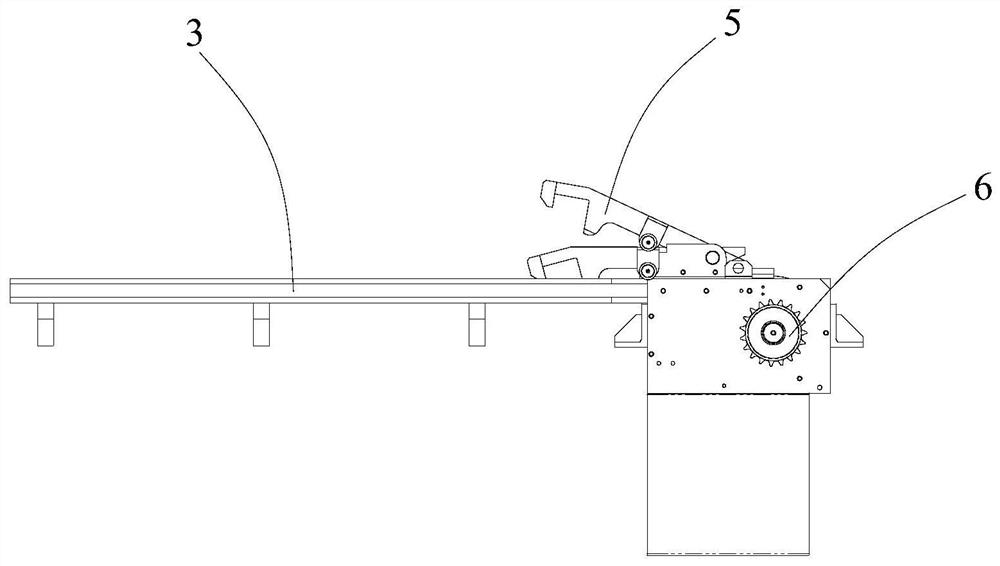

[0022] See Figure 1 to Figure 5 , the double-station two-way mold changing trolley includes four lift-type push-pull mold changing machines 100 , a car body 200 , four auxiliary guide rails 300 and a turning motor 400 .

[0023] The bottom of the car body 200 is provided with wheels or rails to facilitate the movement of the car body 200. Since the internal equipment layout of the factory is generally relatively neat, rails are generally laid between two rows of equipment. The direction of the two rows of equipment for placing molds faces the rails. , the car body 200 can travel along the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com