Double-station die changing trolley

A mold trolley and dual-station technology, applied in the field of dual-station mold-changing trolleys, can solve the problems of reduced work efficiency, large floor space, and lengthened mold-changing trolley structure, so as to improve work efficiency and floor space. Small, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

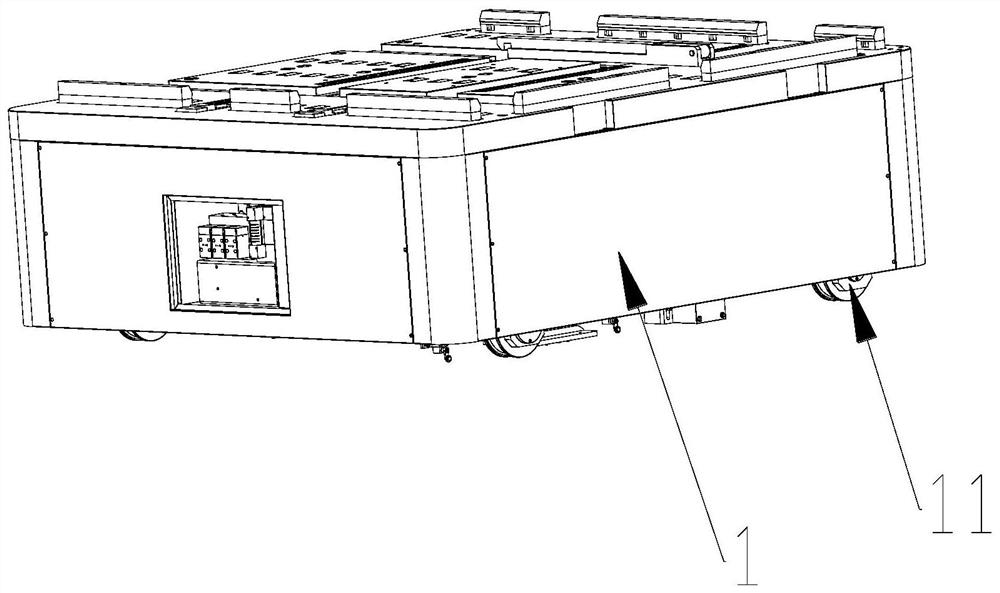

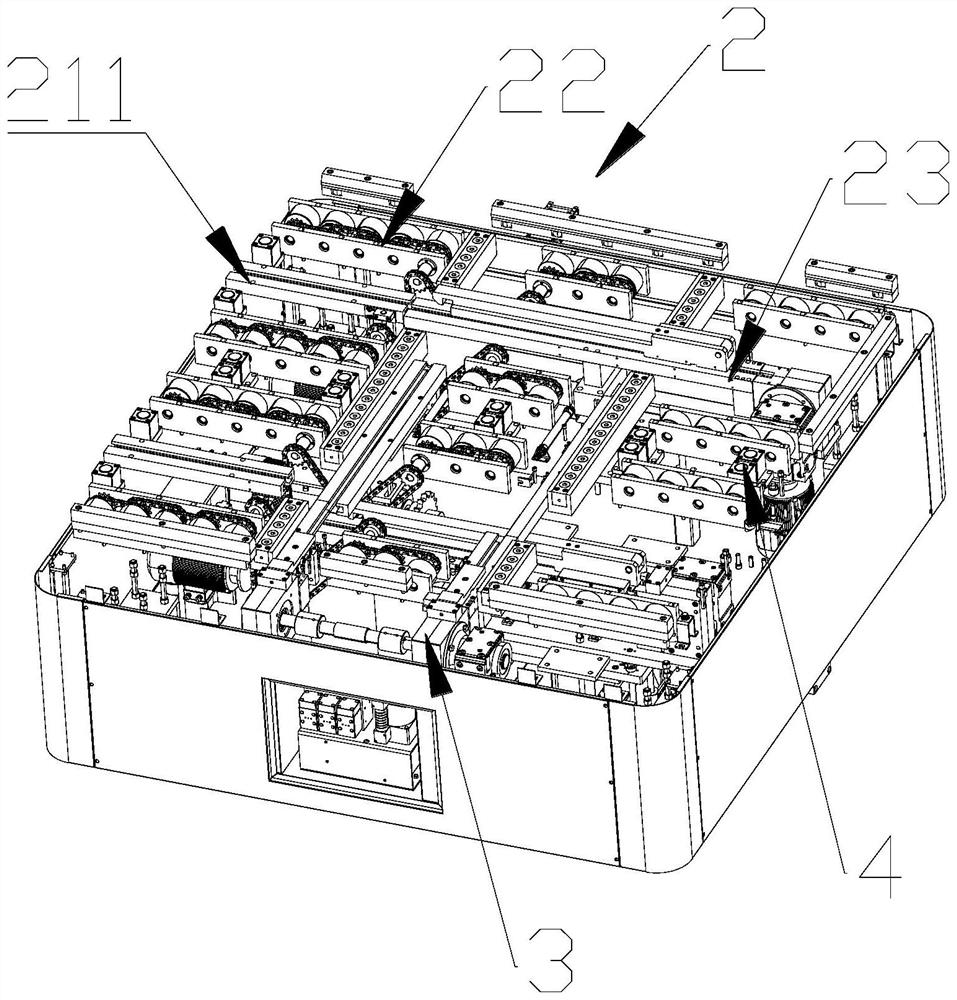

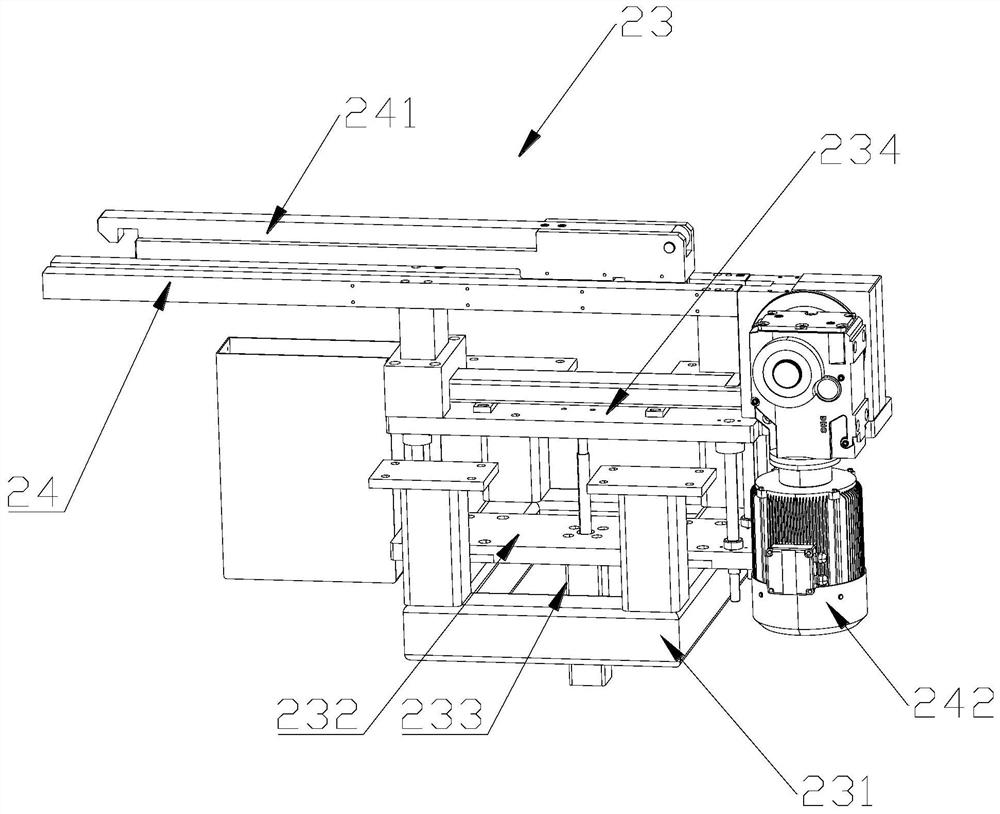

[0018] Such as figure 1 and 2 As shown, a double-station mold change trolley includes a car body 1, a first station and a second station are installed on the car body 1, and the first station includes a dual-power mold change mechanism 2, The dual-power mold change mechanism 2 includes a lifting push-pull mechanism 21 and a roller mechanism 22 positioned on both sides of the lift push-pull mechanism 21, and also includes a push-pull mechanism 3 vertically arranged with the double-power mold change mechanism 2, and the first station and the second The mold positioning block 4 and the first motor that drives the positioning block 4 to lift are arranged between the two stations. The second station has the same structure as the first station; The push-pull mechanism 21 lifts up and pulls out the mold that needs to be replaced in the mold library ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com