Pit punching mechanism for lithium battery packaging equipment

A technology for packaging equipment and lithium batteries, used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficult operation, time-consuming disassembly and assembly, and achieve efficiency improvement, maintenance cost savings, positioning high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following describes the present invention in further detail with reference to the accompanying drawings and specific embodiments, without limiting the scope of implementation of the present invention.

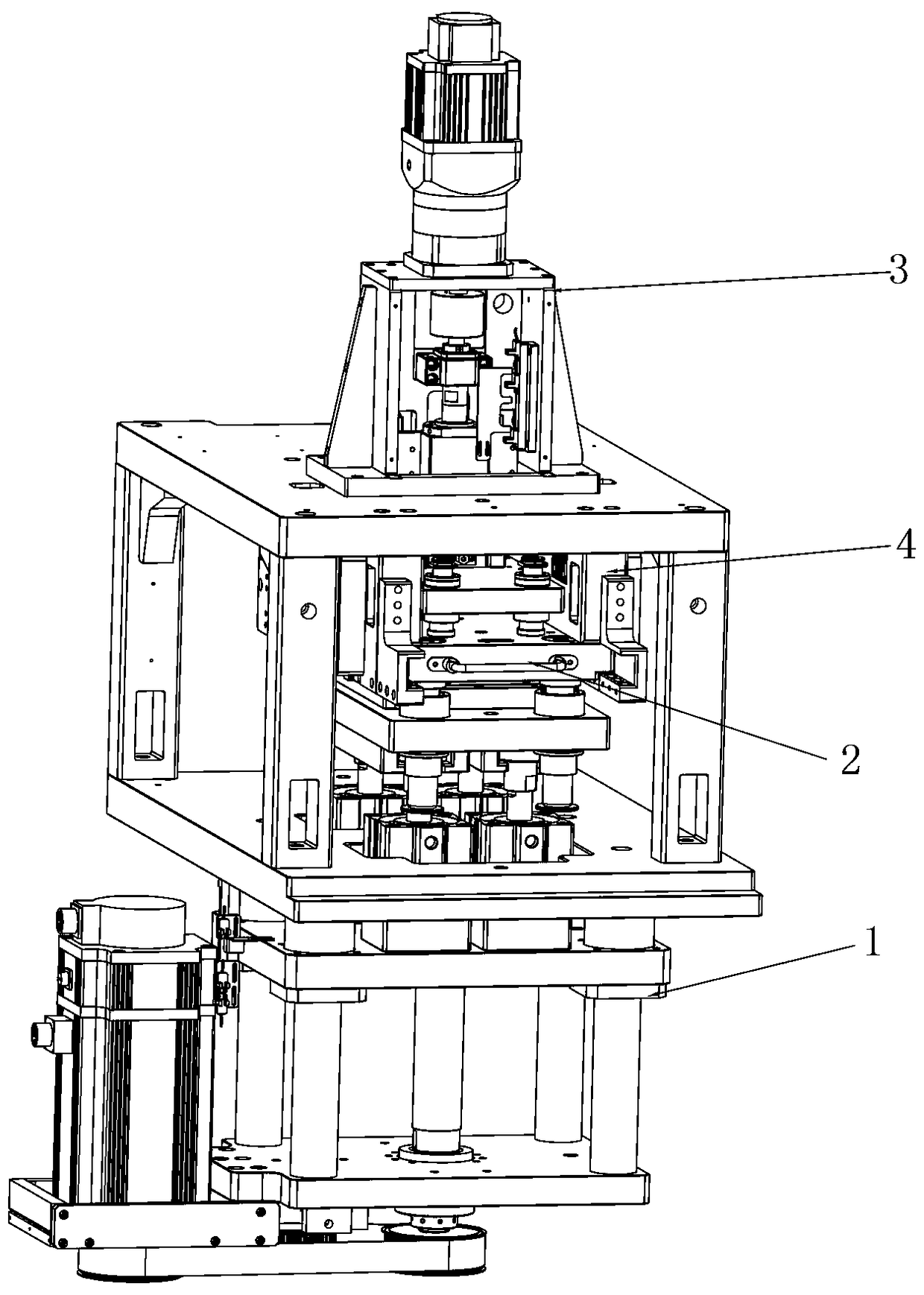

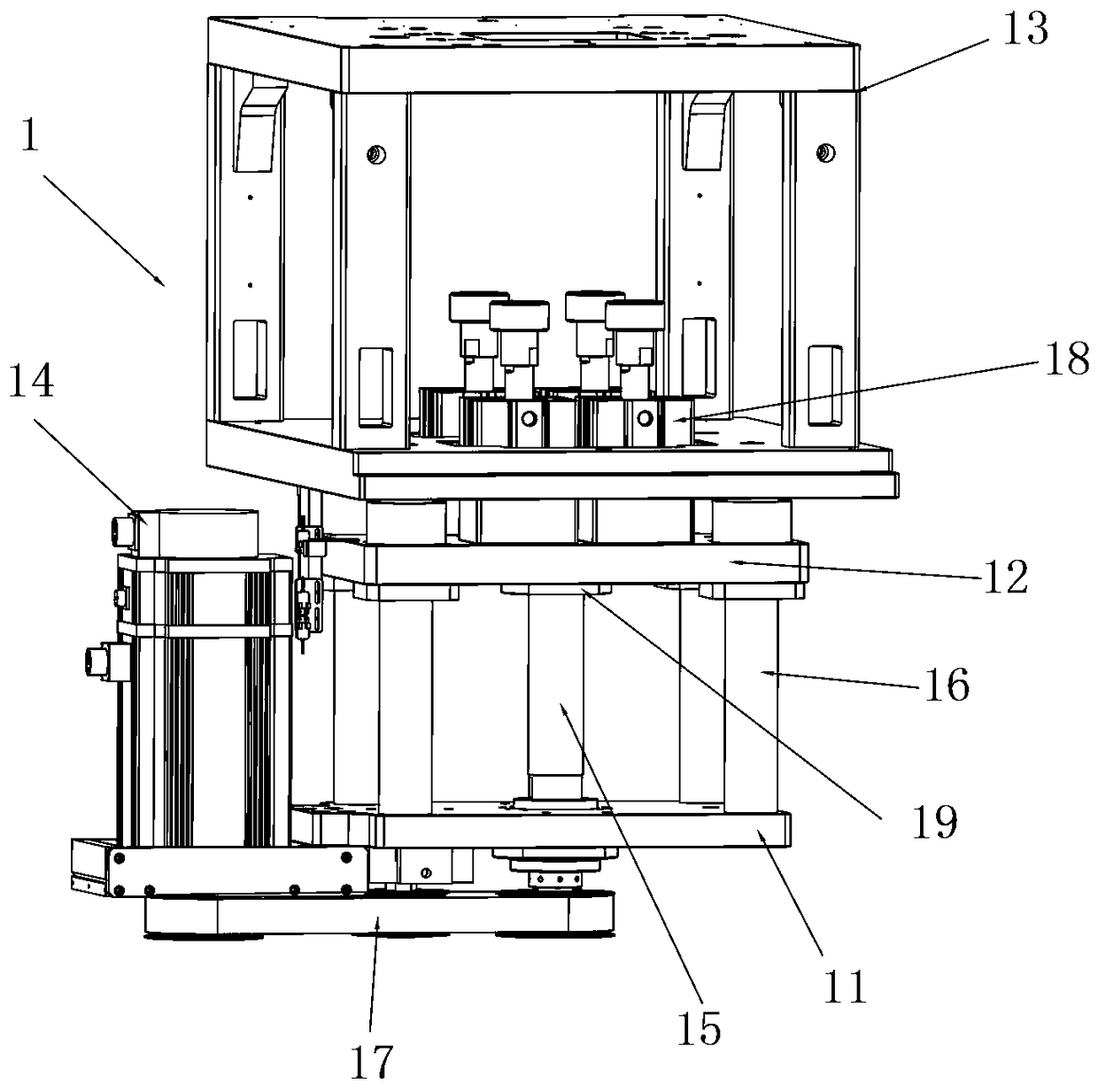

[0028] Such as Figure 1 to Figure 5 As shown, the punching mechanism of a lithium battery packaging device described in this embodiment includes a jacking device 1, a punching mold device 2, a punching drive device 3, and a punching mold fixing seat 4;

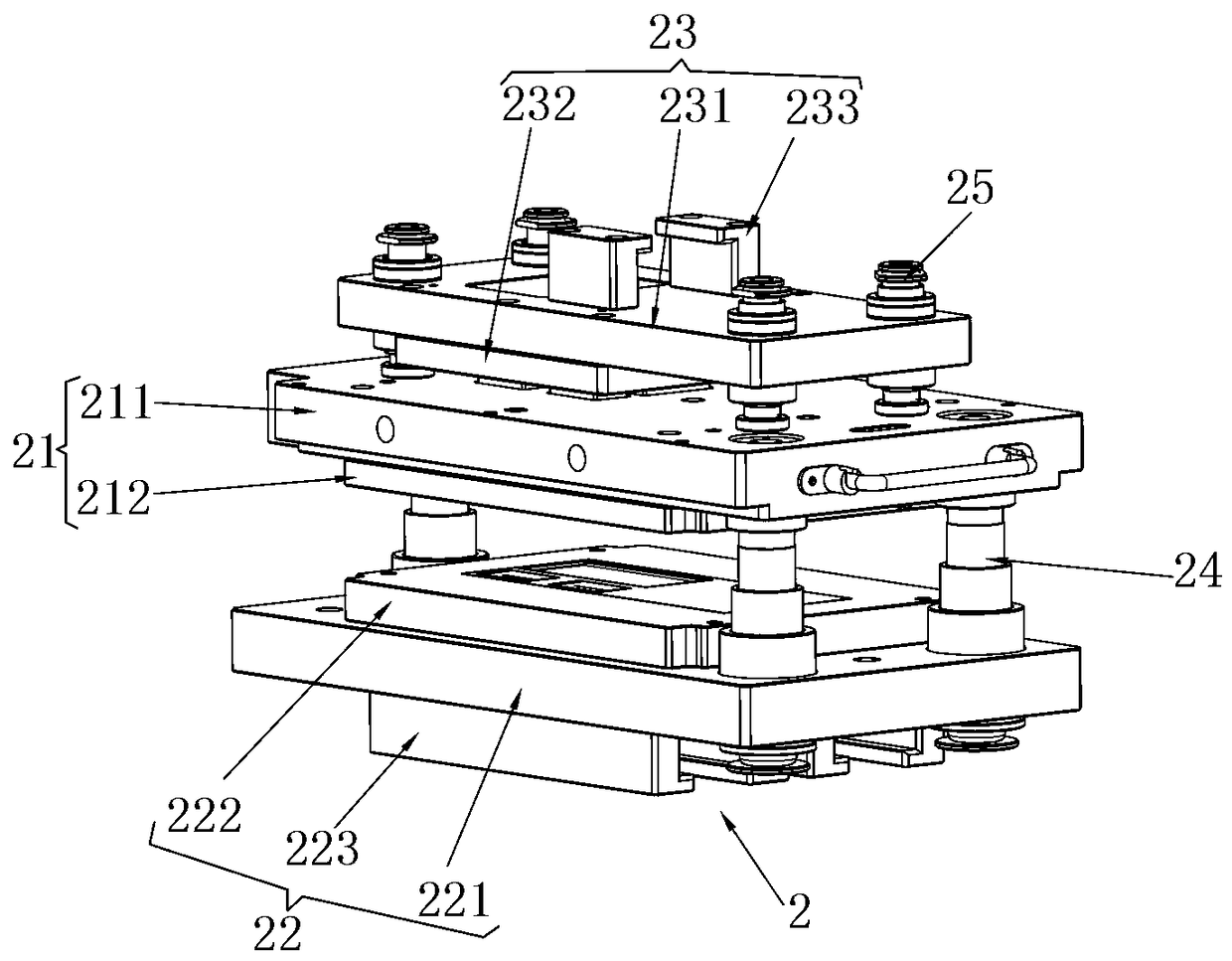

[0029] The punching mold device 2 includes an upper mold assembly 21, a lower mold assembly 22, and a punch assembly 23. The lower mold assembly 22 is fixed to the lower end of the upper mold assembly 21 through a first guide assembly 24, and the lower mold assembly 22 The lower end of the punch assembly 23 is connected to the jacking device 1, the punch assembly 23 is fixed to the upper end of the upper die assembly 21 through the second guide assembly 25, and the upper end of the punch assembly 23 is connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com