Servo press-fitting floating self-locking supporting mechanism

A technology of support mechanism and support structure, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unguaranteed press-fitting depth and verticality yield rate, press-fitting accuracy cannot be guaranteed, product deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

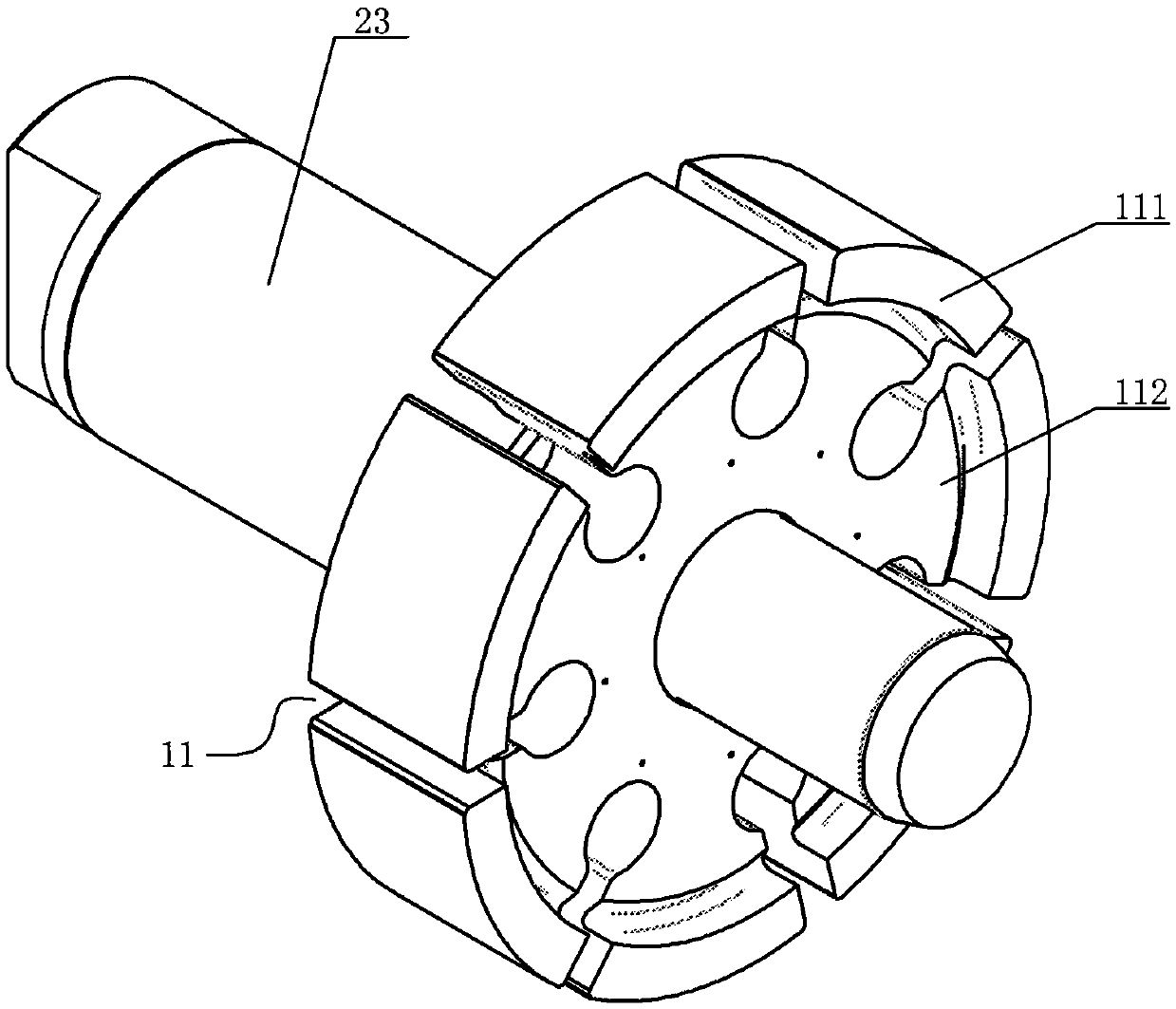

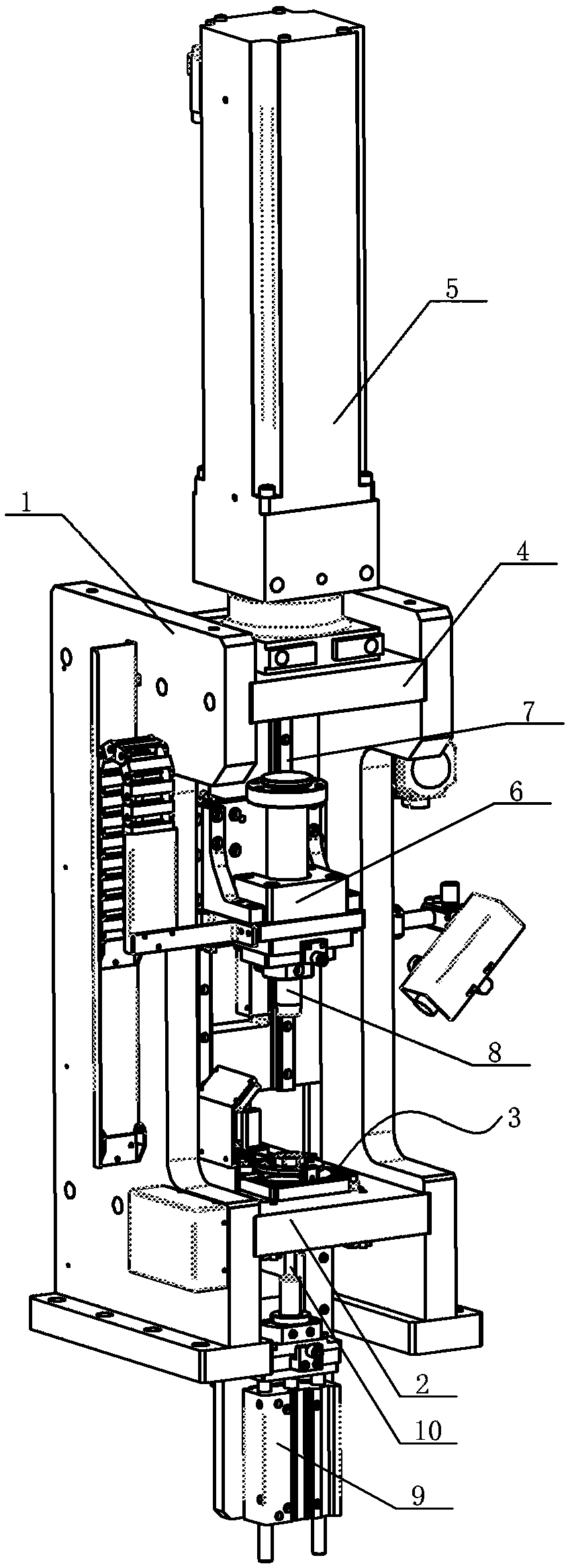

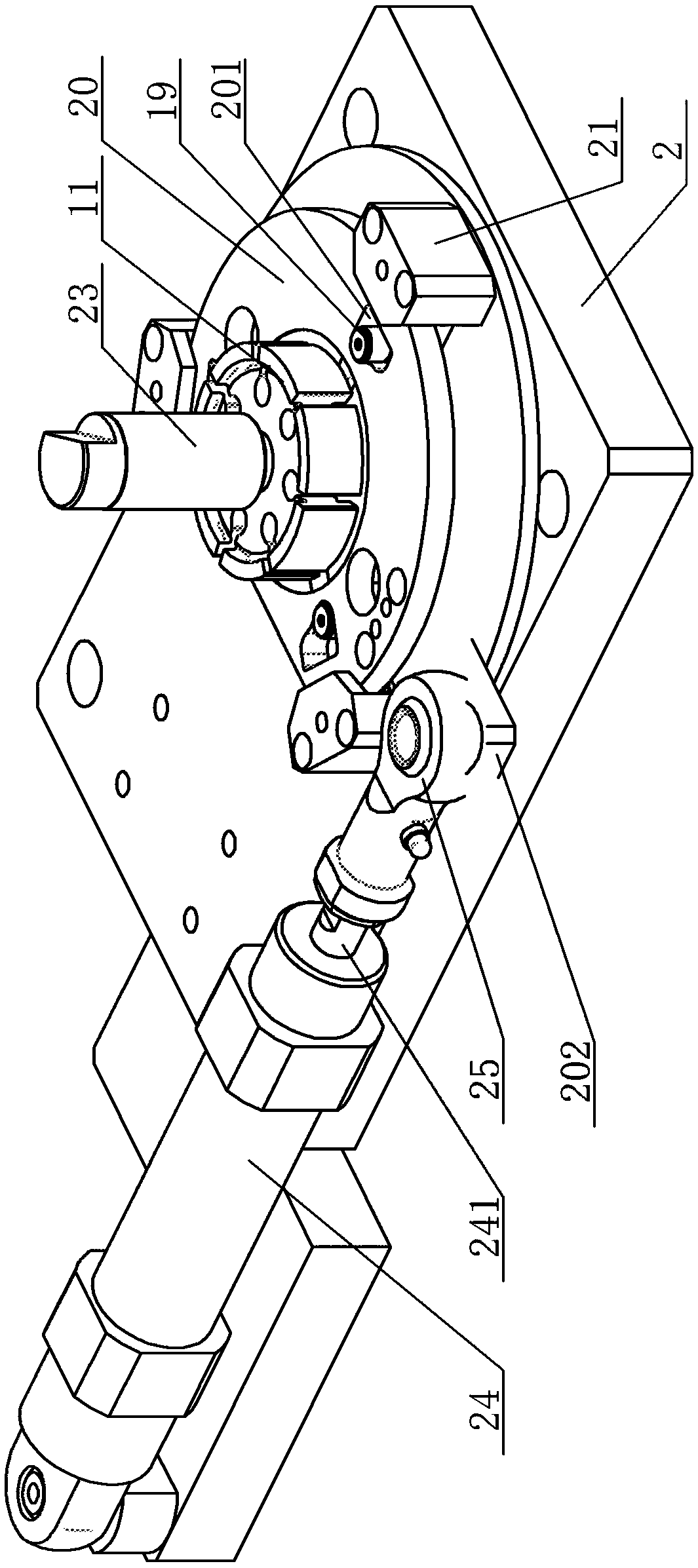

[0021] A servo press-fit floating self-locking support mechanism, see figure 1 : It includes a vertical mounting base 1, a floating self-locking support structure 3 is arranged on the middle horizontal positioning plate 2 of the vertical mounting base 1, a servo press 5 is fixedly installed on the top bracket 4 of the vertical mounting base 1, and the servo press The lower driving end of 5 is fixedly connected to the indenter mounting seat 6, and the back side guide rail of the indenter mounting seat 6 is fitted to the corresponding vertical guide rail 7. Arranged at the upper end of the floating self-locking support structure 3, the bottom of the vertical mounting base 1 is also provided with a vertical positioning cylinder 9, and the upper piston sleeve of the vertical positioning cylinder 9 is provided with a rotor center positioning mold sleeve 10, and the rotor center positioning mold The sleeve 10 is used to locate the initial position of the rotor 11. The floating self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com