Intelligent assembly device of motor worm

A technology for assembling equipment and worms, used in metal processing equipment, workpiece clamping devices, metal processing and other directions, can solve the problems of reducing the service life of product parts, slow changing models, increasing the manufacturing cost of parts, etc., to improve the accuracy of crimping and crimp part quality, quick change bar adjustment, and the effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be further described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

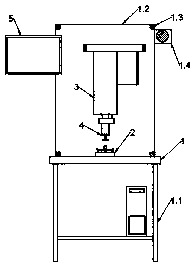

[0026] refer to Figure 1~Figure 4 As shown in the structural diagram, an intelligent motor worm assembly equipment includes a bracket 1, a crimping base 2, a servo motor system 3, a PLC communication control system, and a human-computer interaction interface 5. The bracket 1 includes a support base 1.1 and Equipment box 1.2, safety gratings 1.3 and warning lights 1.4 are installed on the surrounding surface of the equipment box 1.2, which can effectively guarantee the safety of workers and the quality of assembled parts, and can prevent potential danger or problems in assembled parts. Stop the operation of the equipment in time, and run automatically after the danger or problem is solved.

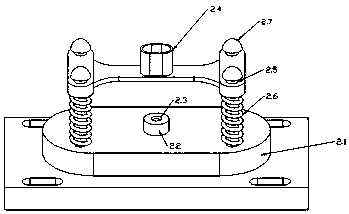

[0027] The crimping base 2 includes a base 2.1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com