Stamping die for automobile part machining

A technology for stamping dies and auto parts, applied in the field of die stamping, which can solve the problems of cumbersome loading and unloading of devices, large manual labor, and low work efficiency, and achieve the effects of reducing manual labor, high practicability, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

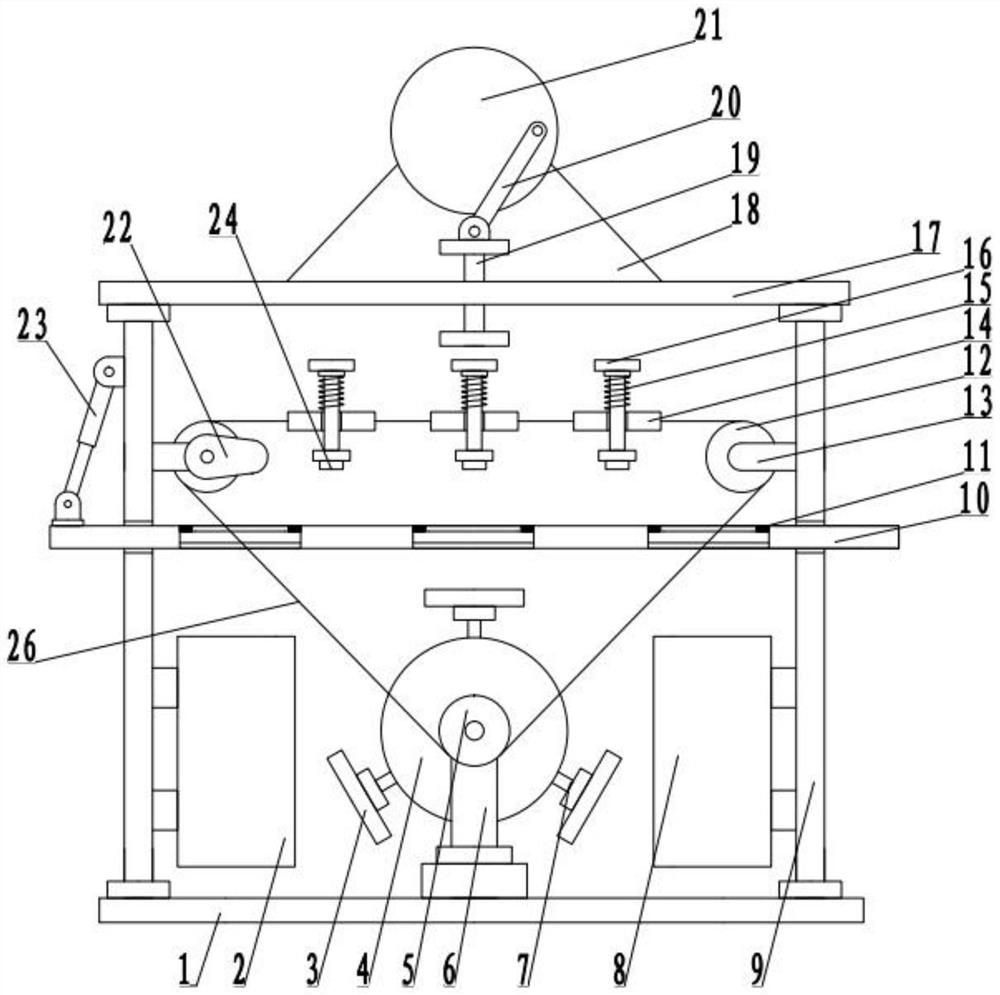

[0025] see Figure 1-4 , a stamping die for processing auto parts, including a base plate 1, and also includes:

[0026] The struts 9 fixedly arranged on both sides of the bottom plate 1, the top of the struts 9 are fixedly connected to the top plate 17;

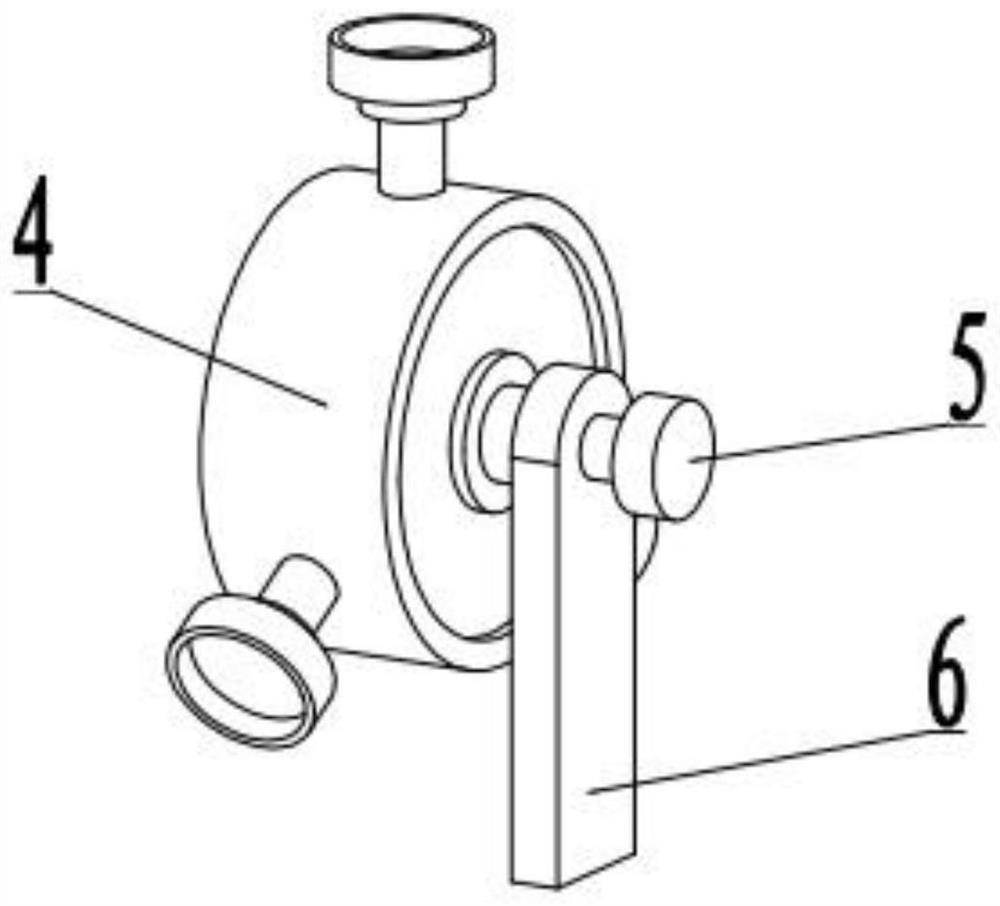

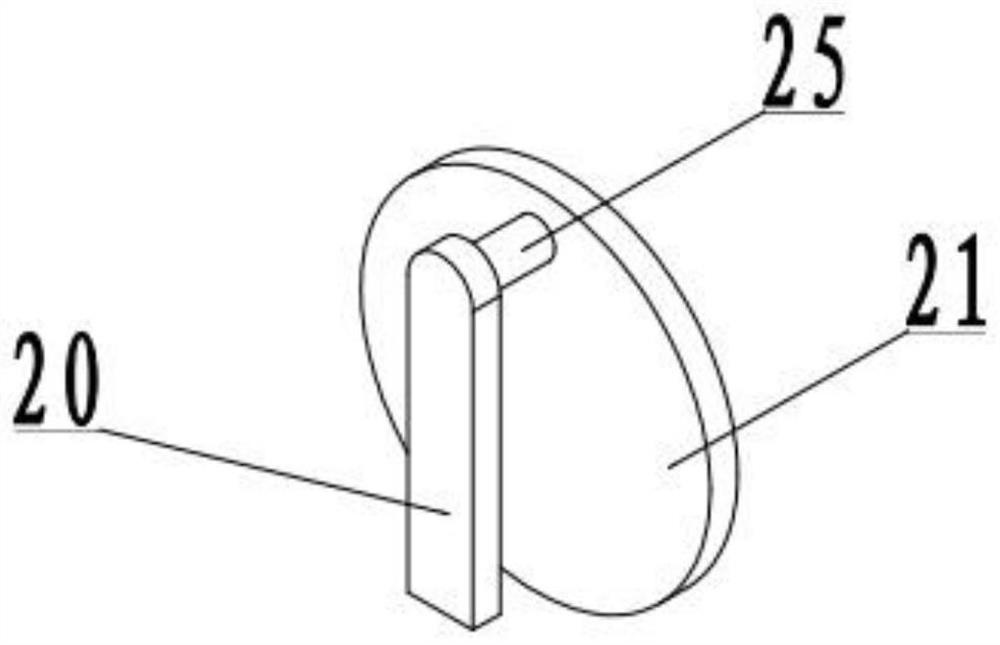

[0027] The conversion mechanism arranged between the poles 9 includes a mounting rod 6, which is fixedly connected to the bottom plate 1, and one side of the mounting rod 6 is connected to the switching disc 4 in rotation, and the rotating shaft of the switching disc 4 is connected to the mounting rod on one side in the axial direction. 6. The side wall is rotatably connected to the installation wheel 5, and the axial side of the rotation shaft of the installation wheel 5 is fixedly connected to the rotation shaft of the conversion disc 4. The conversion disc 4 is fixedly connected to the suction cup 7, and there are multiple suction cups. The mold plate 3 is fixedly adsorbed, the side wall of the installation rod 6 is fixe...

Embodiment 2

[0031] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the telescopic assembly includes a limit block 14, the limit block 14 is fixedly arranged on the transmission belt 26, and the piston is slid through the limit block 14 The rod 16 and the piston rod 16 are T-shaped structures. The elastic member 15 is sheathed on the piston rod 16 . A stamping die is provided at the bottom of the piston rod 16 , and a magnetic head 24 is fixedly provided on the stamping die.

[0032] The feeding mechanism includes a feeding plate 10, the two ends of the feeding plate 10 are slidably connected with the pole 9, the feeding plate 10 is provided with a bearing groove 27, and the two sides of the inner wall of the bearing groove 27 are fixedly connected to the magnet block 11, and the pole 9 The side wall is hinged with an electric telescopic rod 23, and one end of the electric telescopic rod 23 is hinged with the feeding plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com