Die changing trolley of press machine and die changing method

A mold changing trolley and press technology, which is applied in the field of presses, can solve the problems of long downtime for mold changing, difficult replacement and transportation, and increased labor intensity of operators, so as to shorten the mold changing time, quickly change, and change molds convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

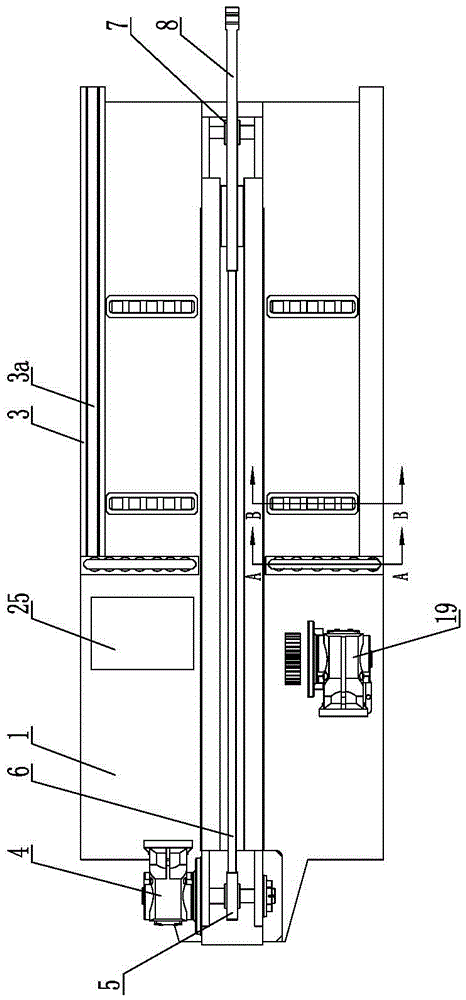

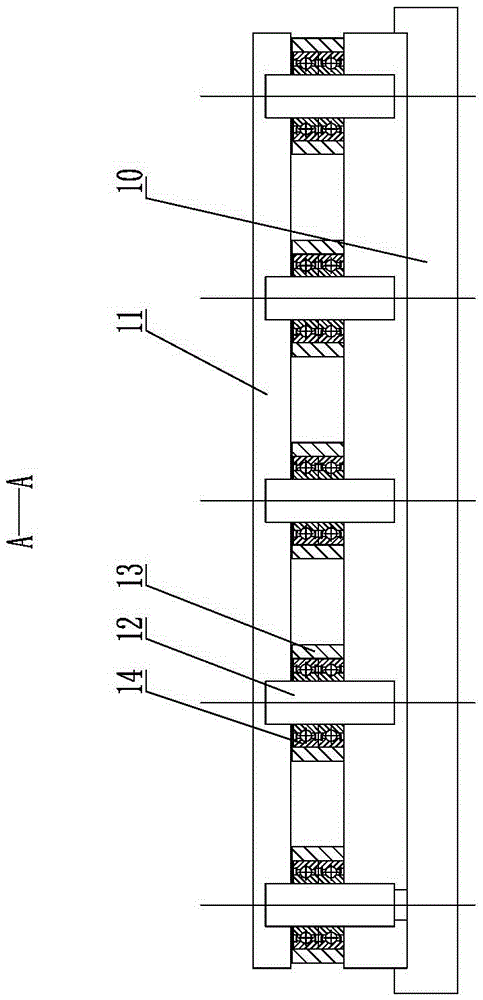

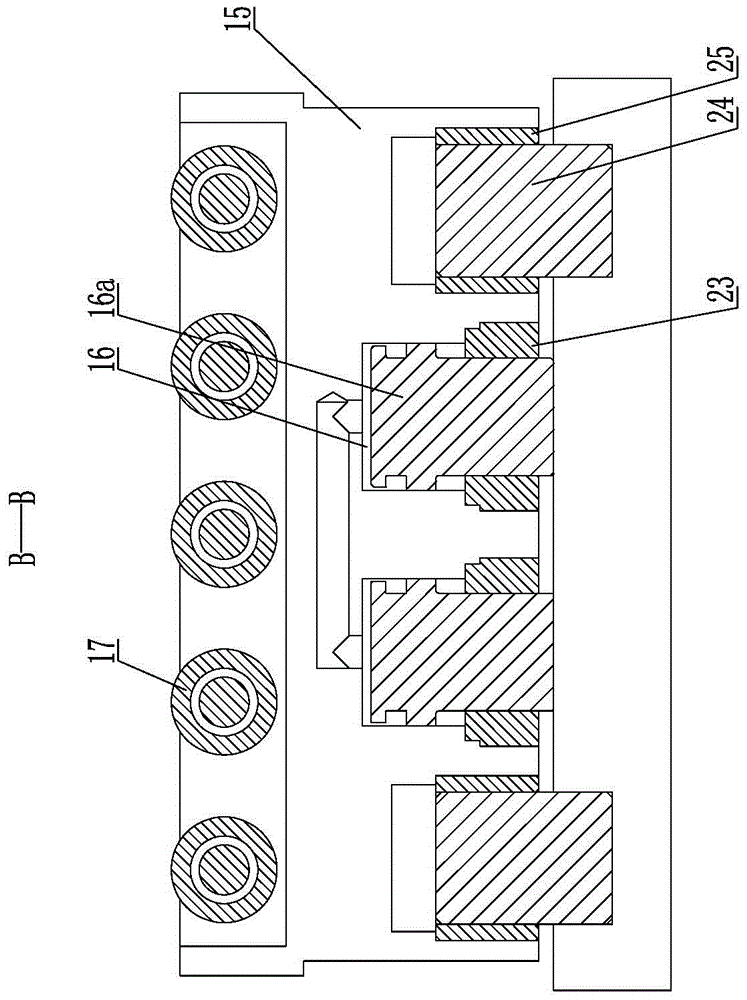

[0026] Such as Figure 1-7 As shown, it is a press mold changing trolley, including a body 1, wheels 2 are arranged on the bottom of the body 1, a driving mechanism is arranged on the body 1, and a pair of mold carrier guide rails 3 are arranged in parallel on the left and right sides of the body 1, at least one mold carrier The guide rail 3 is provided with an outer convex guide strip 3a, and the vehicle body 1 is provided with a mold carrier push-pull mechanism that pulls the mold carrier to move on the mold carrier guide rail 3. The mold carrier push-pull mechanism includes a push-pull motor 4, and the output end of the push-pull motor 4 is provided There is a pulley 5, which is connected to the pulley 2 7 fixed on the car body 1 via a belt. The belt 6 is parallel to the guide rail 3 of the mold base. The belt 6 is connected with a sliding hook 8 connected to the mold base; the lower part of the mold base Corresponding to the outer convex guide bar 3a is provided with a doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com