Die changing trolley with lifting and quick positioning functions

A technology of mold trolley and lifting table, which is applied in the field of mold changing trolley with lifting and fast positioning, which can solve the problems of difficulty in lifting and adjusting the mold table, difficulty in meeting the needs of use, and single function, so as to improve the efficiency of mold changing , Simple and reasonable structure, high mold change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

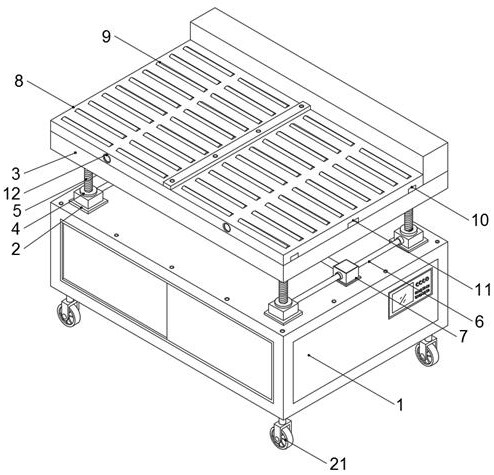

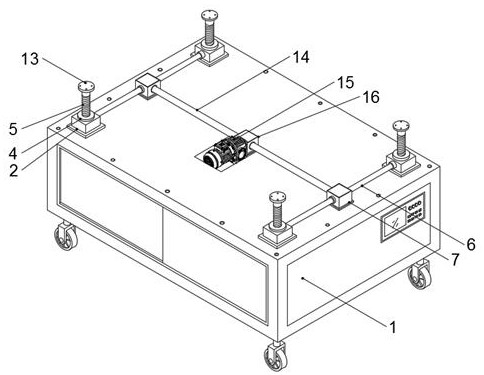

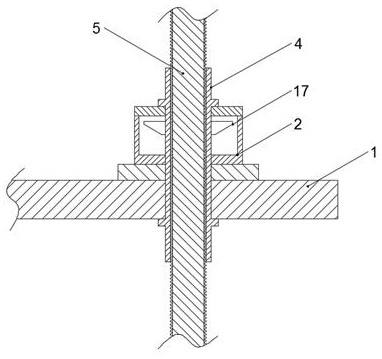

[0024] Example: such as Figure 1-4 As shown, a mold changing trolley with lifting and quick positioning of the present invention includes a main body 1, and fixed seats 2 are installed at the top four corners of the main body 1, and rotating sleeves are installed at the top of the fixed seats 2. 4. A pair of connecting seats-7 are fixedly installed on the top side of the main vehicle body 1, and the connecting seats-7 are respectively installed between the fixed seats 2, and the front and rear sides of the connecting seat-7 are connected to the transmission shaft-6 , the other end of the transmission shaft 6 is respectively connected to one side of the fixed seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com