Locking mechanism and bending die quick clamping system including locking mechanism

A locking mechanism and clamping technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high mold precision requirements for segmented molds and loose clamping of segmented molds, so as to eliminate safety problems , The clamping force does not attenuate, and the effect of avoiding torsional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

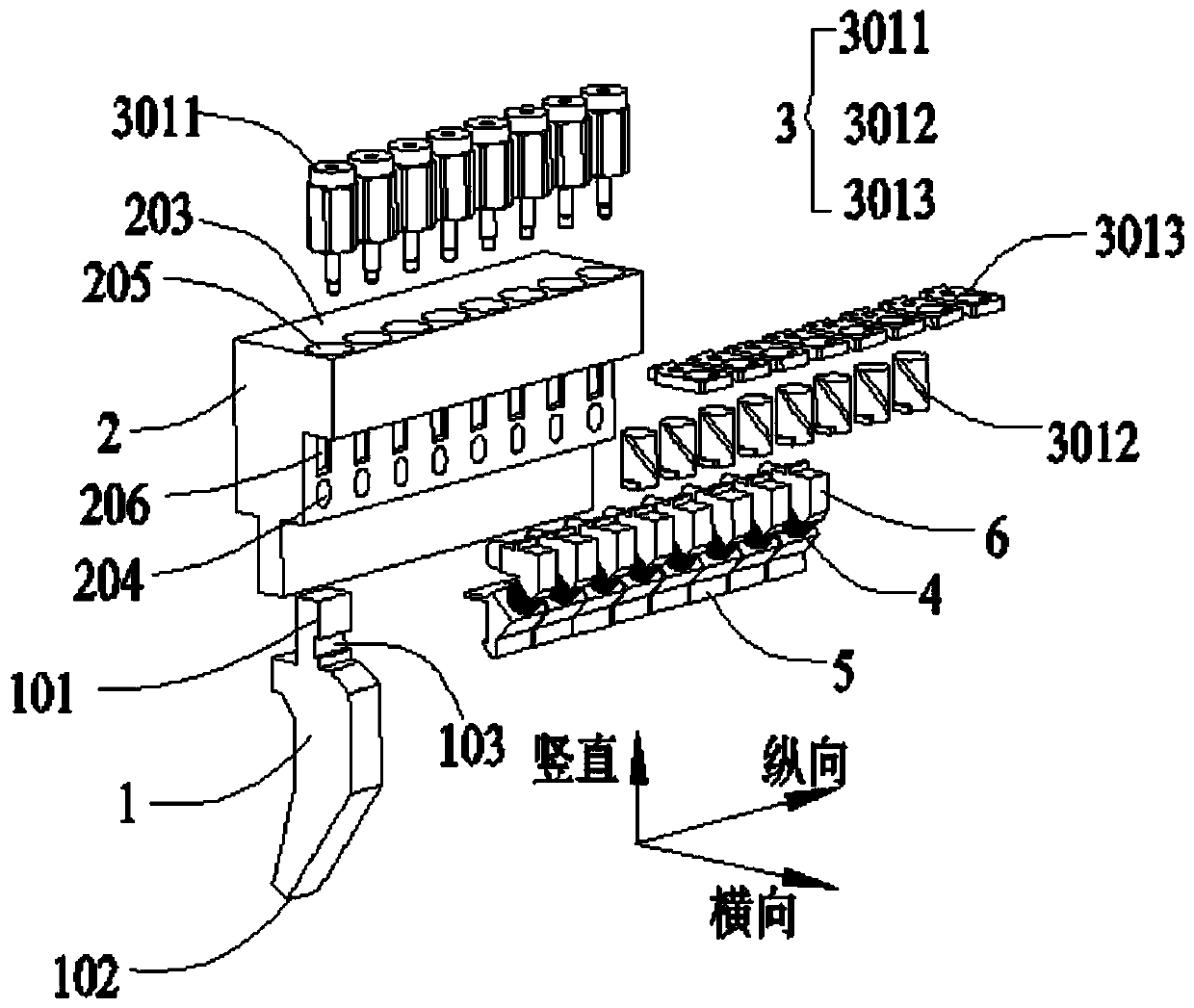

[0075] Embodiment 1, a locking mechanism, such as figure 1 , Figure 13-Figure 15 As shown, it includes an installation base 2 and a clamping executive assembly. One or more groups of clamping executive assemblies are arranged longitudinally on one or both sides of the installation base 2, and the mold is clamped to the clamping executive assembly. Between the installation base 2, the clamping execution assembly approaches or moves away from the installation base 2 along a plane perpendicular to the longitudinal direction; and, adjacent to the clamping execution assembly is arranged closely.

[0076] The installation base 2 is a fixed part, and the installation base 2 is fixed on the bending machine. The movement direction of the clamping actuator assembly is perpendicular to its arrangement direction, so when the clamping actuator assembly clamps the mold, the adjacent clamp There will be no interference between the clamping actuators, and the distance between the adjacent c...

Embodiment 2

[0082] Embodiment 2, on the basis of Embodiment 1, the locking actuator assembly further includes an elastic body 4 located between the anti-drop locking hook 5 and the locking tooth 6; the elastic member 4 is suitable for squeezing the anti-drop locking hook 5 , and apply a force towards the vertical reference plane 202 to the clamping part 101 of the upper mold through the anti-drop lock hook 5, the force can be the total force or a component force, that is, the direction of the elastic force of the elastic member 4 can be directly opposite to the vertical The direction of the straight reference plane 202 may also extend obliquely to the direction of the vertical reference plane 202 .

[0083] The force exerted by the third working surface 502 of the anti-drop lock hook 5 on the upper mold 1 is vertically upward for supporting the upper mold 1, and the third working surface 502 and the horizontal reference plane 201 jointly limit the displacement of the upper mold 1 in the ve...

Embodiment 2a

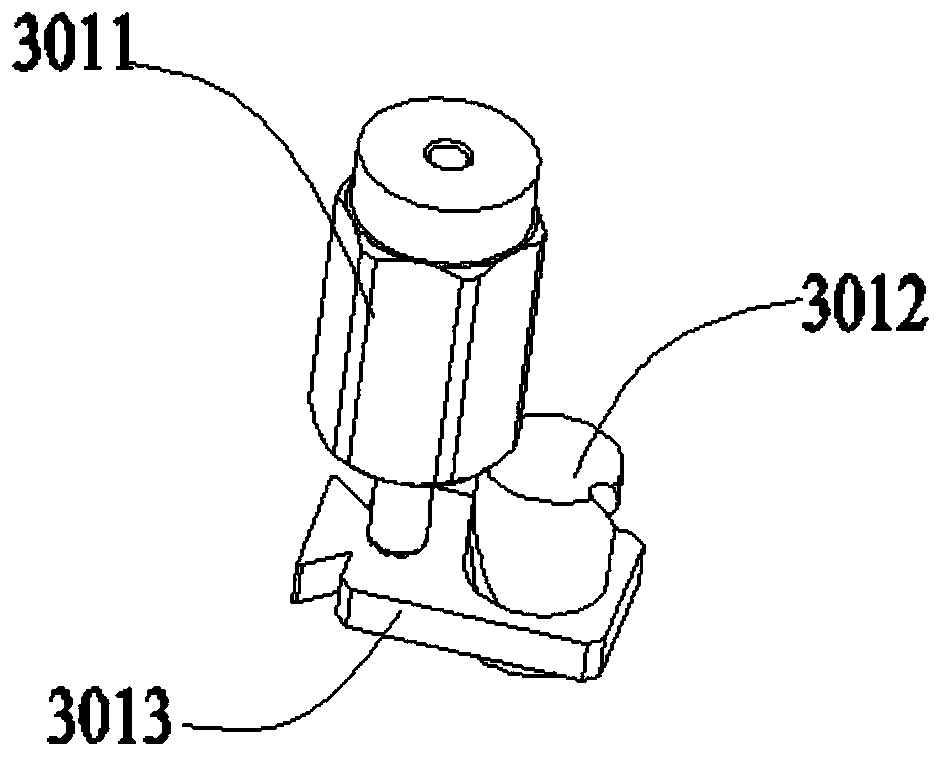

[0087] Embodiment 2a is used for an asymmetric mold, and the fourth working surface 604 is a circular curved surface. Such as Figure 16 As shown, the matching structure between the anti-drop lock hook 5 and the locking tooth 6 is: the bottom of the locking tooth 6 extends obliquely downward with a positioning column 603, and the fourth working surface 604 is the circumferential surface of the positioning column 603, away from the upper One end of the anti-drop locking hook 5 of the clamping part 101 is provided with a positioning groove 503 coupled with the positioning post 603 , and the elastic member 4 is sheathed on the circumferential surface of the positioning post 603 . The positioning column 603 extends toward the installation base 2 .

[0088] The structure on one side of the anti-drop locking hook 5 that cooperates with the upper mold 1 is as follows: a protruding hook 501 facing the direction of the installation base 2 is provided at the bottom of the second workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com