Sorgo rod skin and core separating device

A separation device and skin-core technology, applied in bark, plant material mechanical processing, wood processing equipment, etc., can solve the problems of laborious and laborious, hard to control, and different depths of millet stalks, and achieve high quality and deep uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

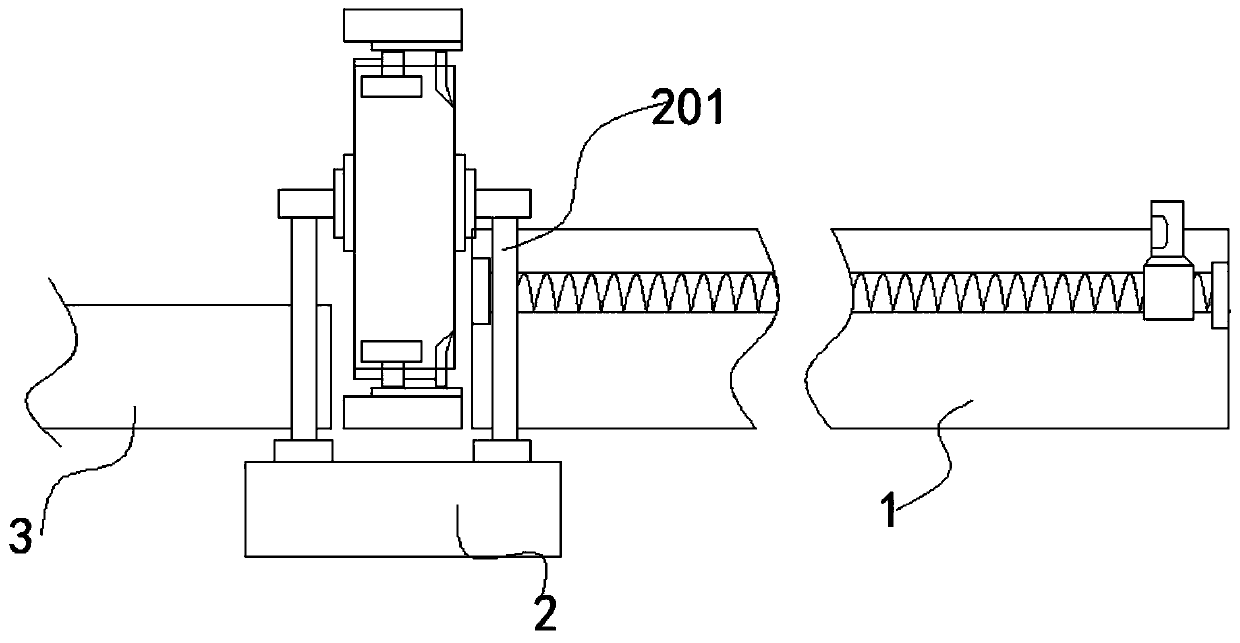

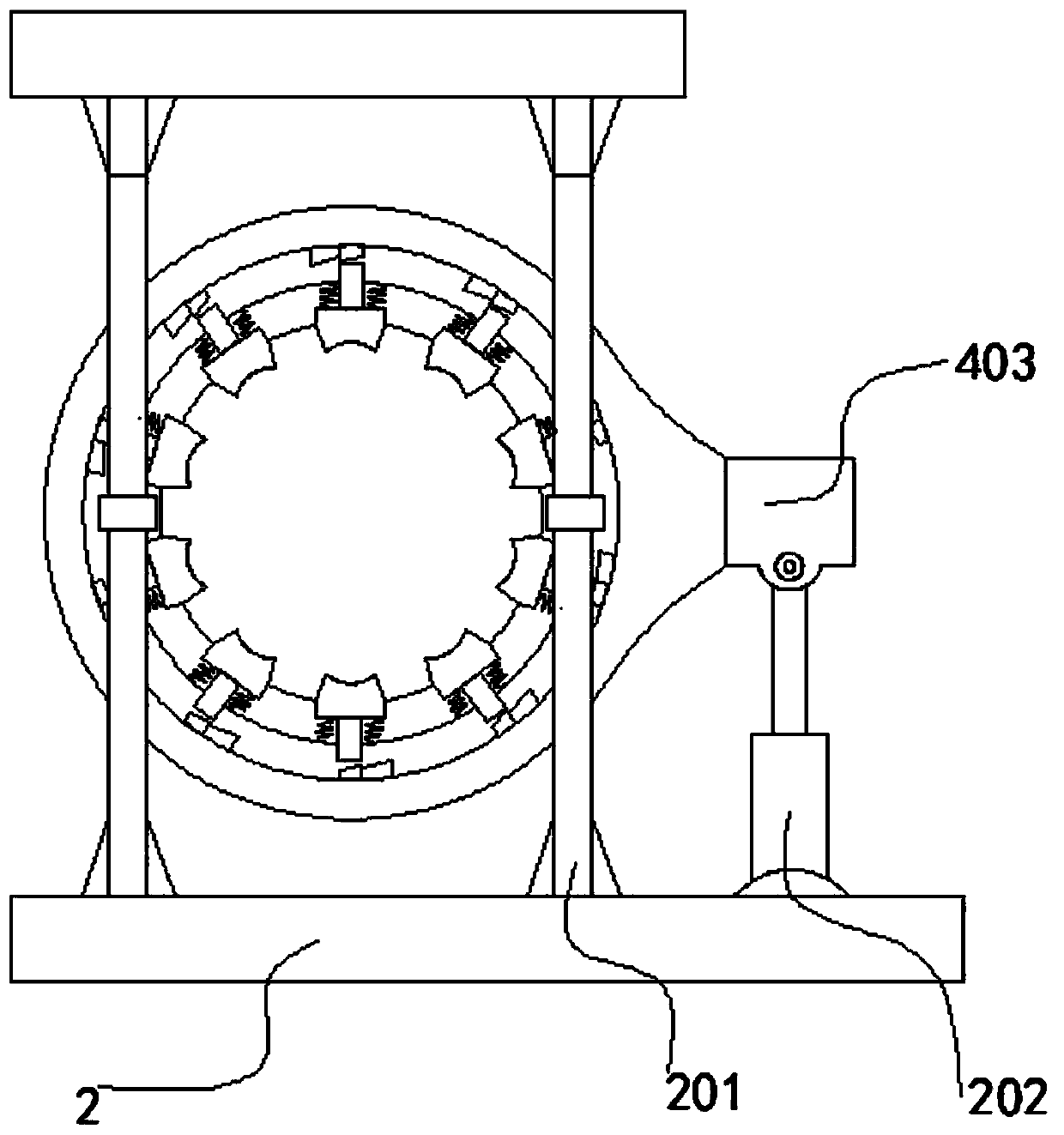

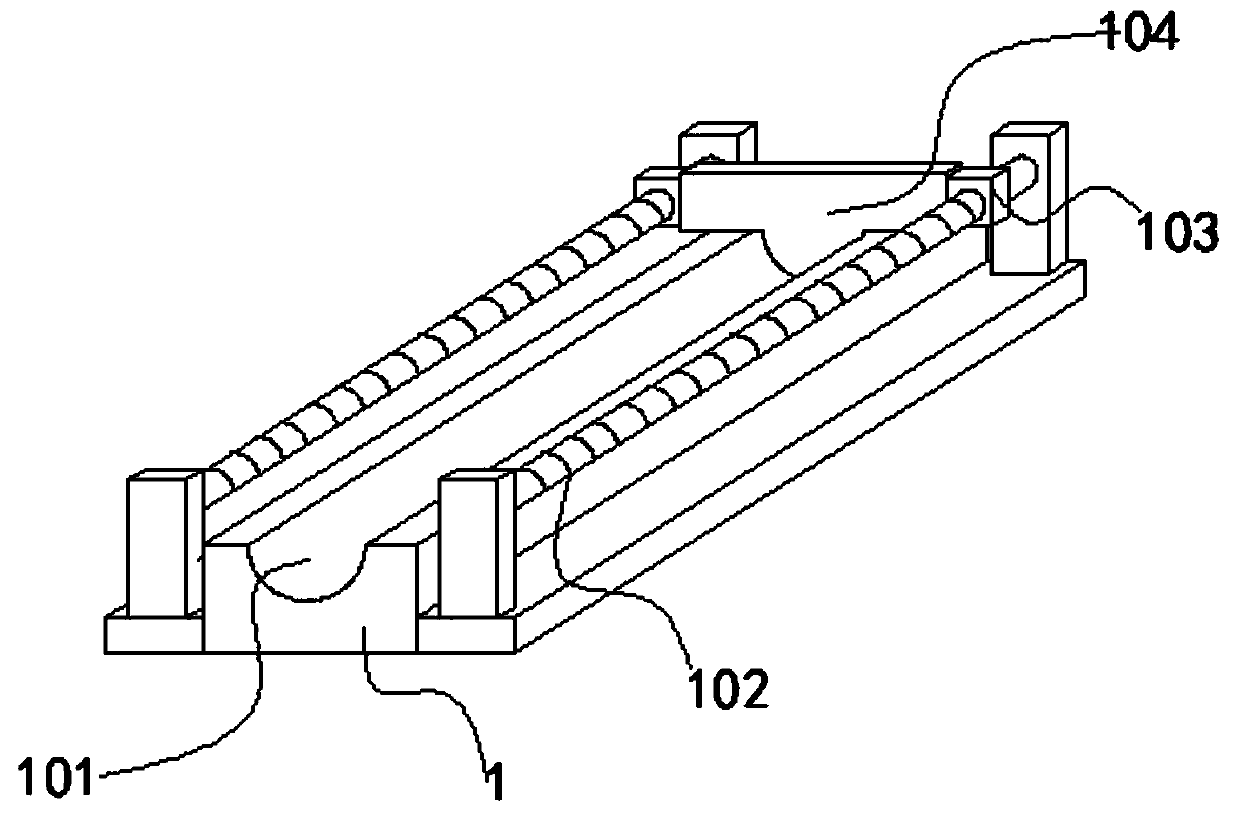

[0031] as attached figure 1 To attach Figure 7 Shown:

[0032] The invention provides a skin-core separation device for millet stalks, which includes a feeding trough 1, a frame plate 2, a discharge trough 3, a rotating ring 4, a fixed ring 5, a first splint 6, and a tension spring 7. The second splint 8, placement slot 101, lead screw 102, lead screw motor 103, push plate 104, bracket 201, electric telescopic rod 202, first slider 401, second slider 402, connecting shaft 403, positioning shaft 404, limit groove 501, clamping surface 601, first top block 602, cutting knife 801 and second top block 802; shelf plate 2 is located between feed chute 1 and discharge chute 3, directly above feed chute 1 A placement trough 101 is integrated, and a lead screw 102 is fixedly connected to the left and right sides above the feed trough 1. A lead screw motor 103 is nested outside the lead screw 102, and a push plate 104 is welded between the two lead screw motors 103 A bracket 201 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com