Core unloading device of sand core assembly

A sand core and core assembly technology, which is applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problems of unstable core setting, sand rubbing of the lower core, and increased production costs, so as to achieve convenient adjustment and avoid incorrect core setting. Stabilize and reduce the effect of casting waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments may enable those skilled in the art to fully understand the present invention, but they do not limit the present invention to the scope of the described embodiments.

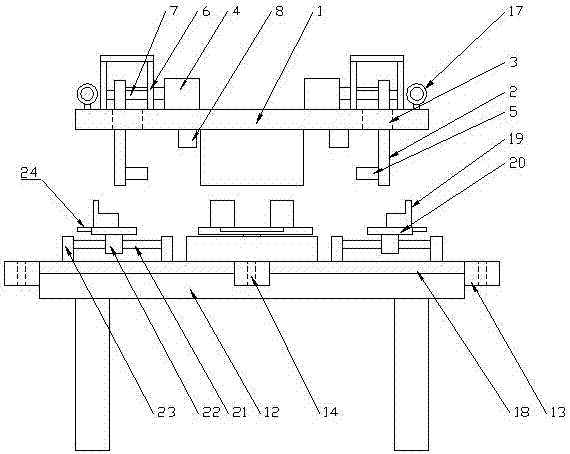

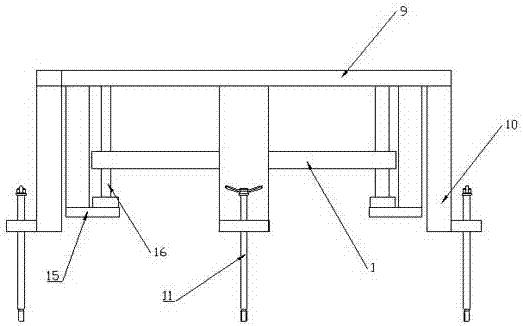

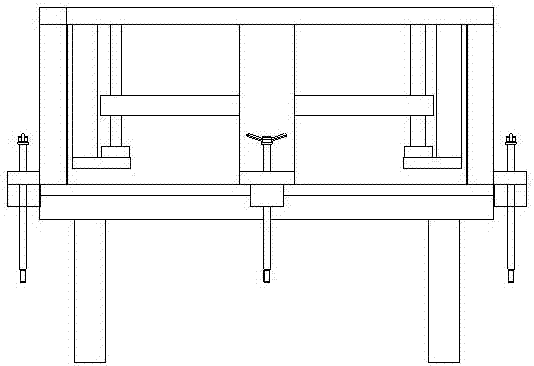

[0028] Such as Figure 1-Figure 4 A sand core assembly core lowering device is shown, which is used to assemble and clamp the combined sand core to facilitate subsequent hoisting by crane, including

[0029] A sand core moving unit is located at the upper end. The sand core moving unit includes a sand core moving support 1 on which a clamping mechanism for clamping the sand core is installed.

[0030] The sand core clamping mechanism includes four sand core clamping plates 2 distributed in a rectangular shape. At the same time, the sand core moving support 1 also has four through holes 3 through which the sand core clamping plates 2 pass up and down. The plate 2 is vertically arranged in the through hole 3, and the upper end of the sand core clamping plate 2 extends out of the sand cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com