Method for producing C-shaped hardwares of plastic steel door window

A plastic-steel door and window and a manufacturing method technology, applied in the field of C-shaped parts manufacturing, can solve the problems of undisclosed C-shaped parts process, intermittent independent process of manufacturing steps, and unguaranteed accuracy, so as to save processing work, save equipment, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

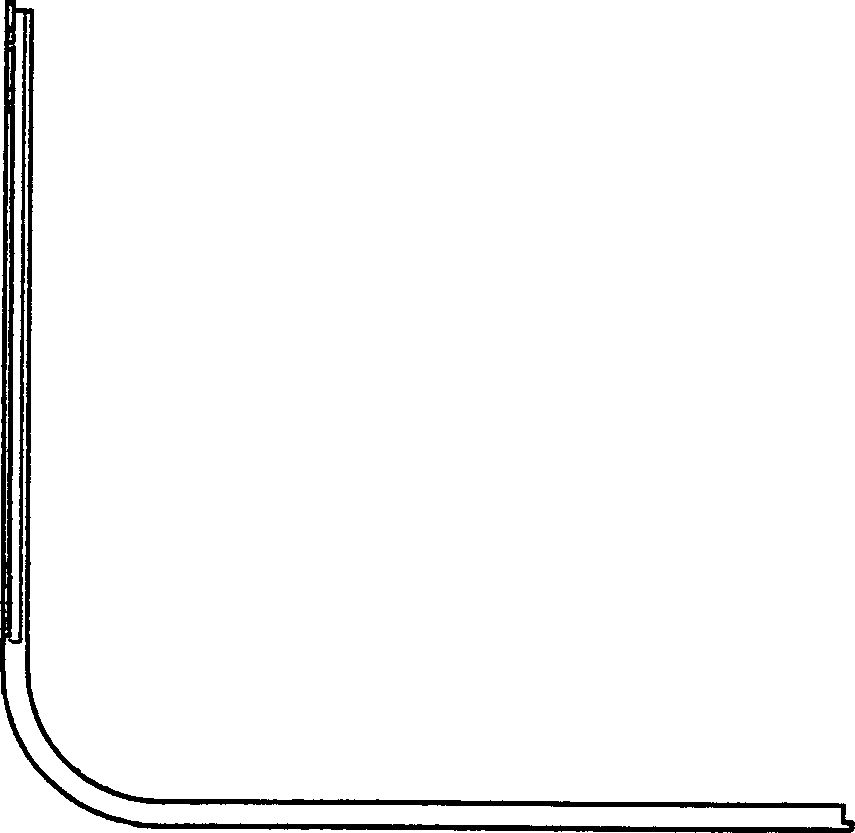

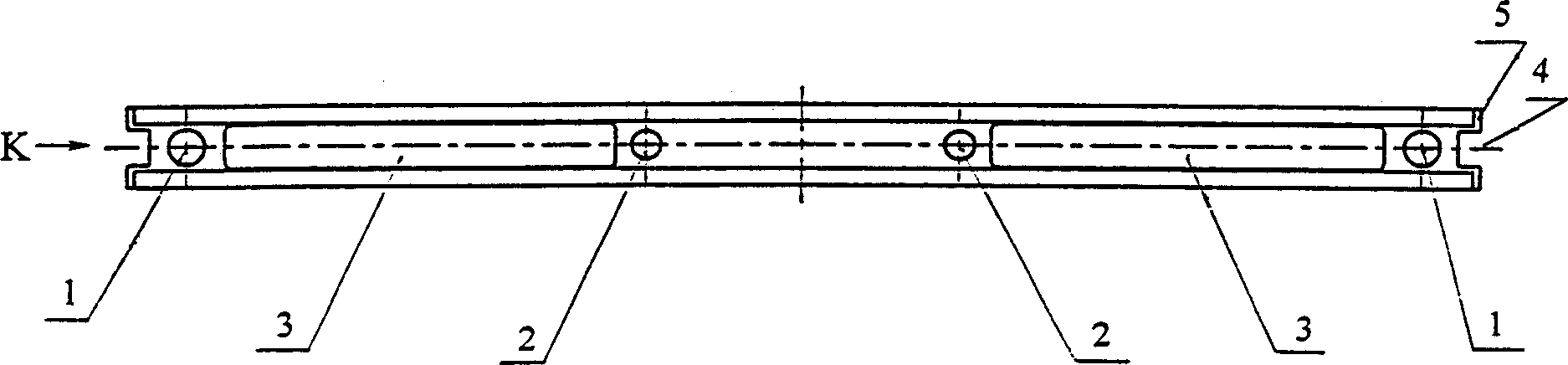

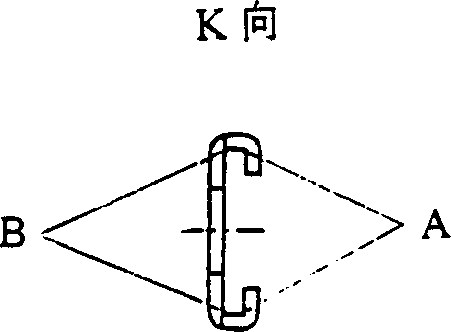

[0014] Such as figure 1 , figure 2 and image 3 The 90°C shaped part to be manufactured as shown is made by continuous processing according to the following process steps, such as Figure 4 In the process flow shown, the first row uncoils the coiled strip steel 6 on the uncoiler 10, and after being controlled by the first buffer storage device 11, the strip steel 6 is stably sent into the continuous forming machine 12, and the continuous cold bending is formed into The C-shaped section makes the gap between the grooves at the corners reach the requirement of 0.9 mm or more, and then controlled by the second buffer storage device 13, it is fed into the punching machine 18 stably and accurately by the automatic feeder 14, because the punching machine 18 The working part is equipped with punching notch device 15, punching, cutting die 16 and bending device 17, so the following process can be completely completed on the punching machine 18, first punch out the gap 5 by the punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com